Method for regenerating cathode material of waste lithium ion battery through electrolysis of molten alkali

A lithium-ion battery, cathode material technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of high cost, easy secondary pollution, complex process flow, etc., achieve high recovery efficiency, is conducive to recovery, metal resources The effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

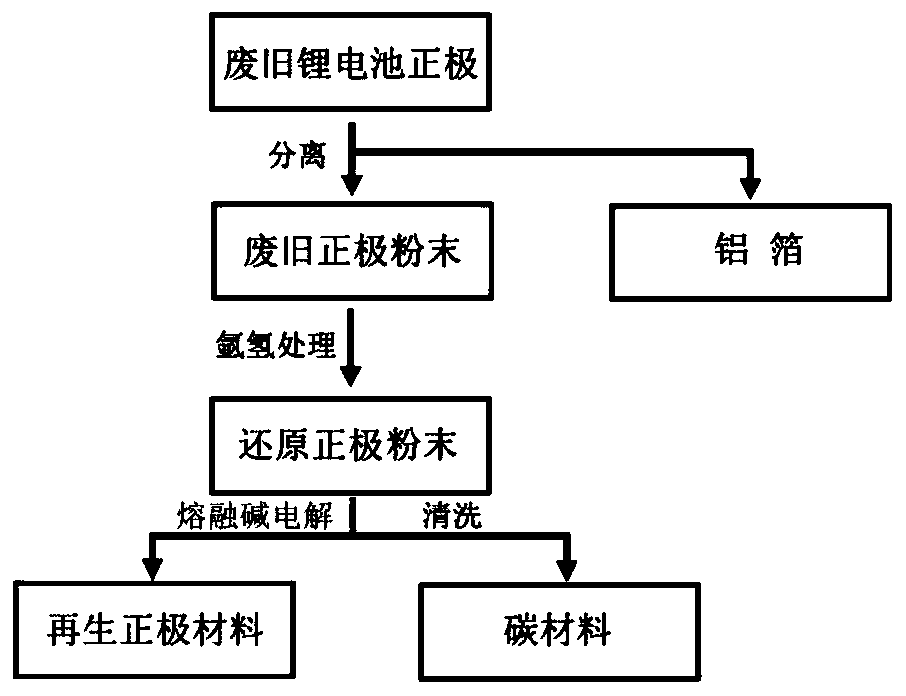

[0034] Example 1 is to prepare the regenerated high-quality lithium cobaltate positive electrode material by one-step electrolysis in the mixed molten alkali system of KOH and LiOH by pre-reducing the processed waste lithium ion battery positive electrode lithium cobaltate material, such as figure 1 As shown, the specific steps are:

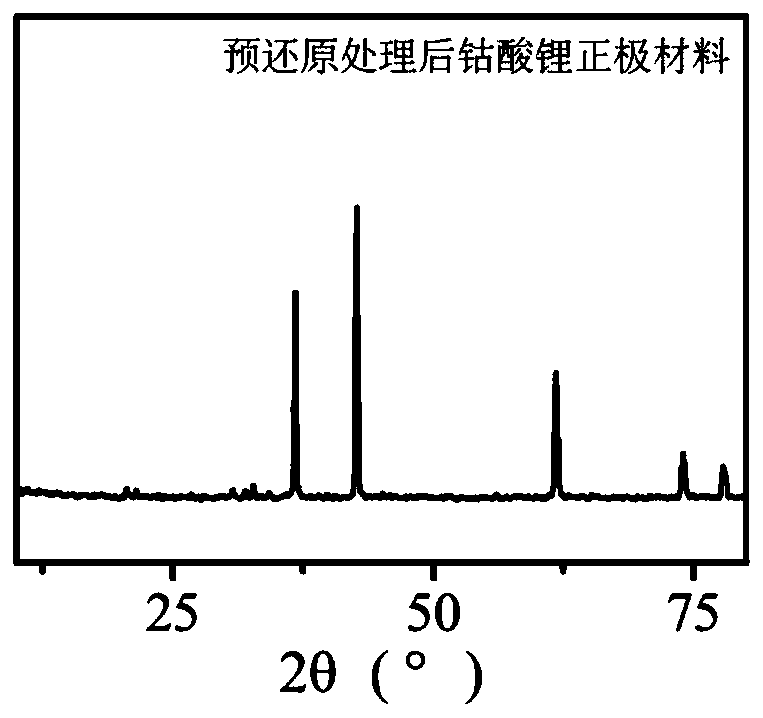

[0035] (1) Pretreatment of waste lithium-ion battery positive electrode materials: Disassemble the waste lithium cobalt oxide battery after discharge treatment, put it into a reduction tube furnace, pass in argon-hydrogen mixed gas, and control the H 2 Velocity is 50 m 3 / h, control the flow rate of Ar to 50 m 3 / h, after heating up to 200°C and keeping it warm for 2 h, scrape off the treated waste lithium cobaltate powder from the aluminum foil;

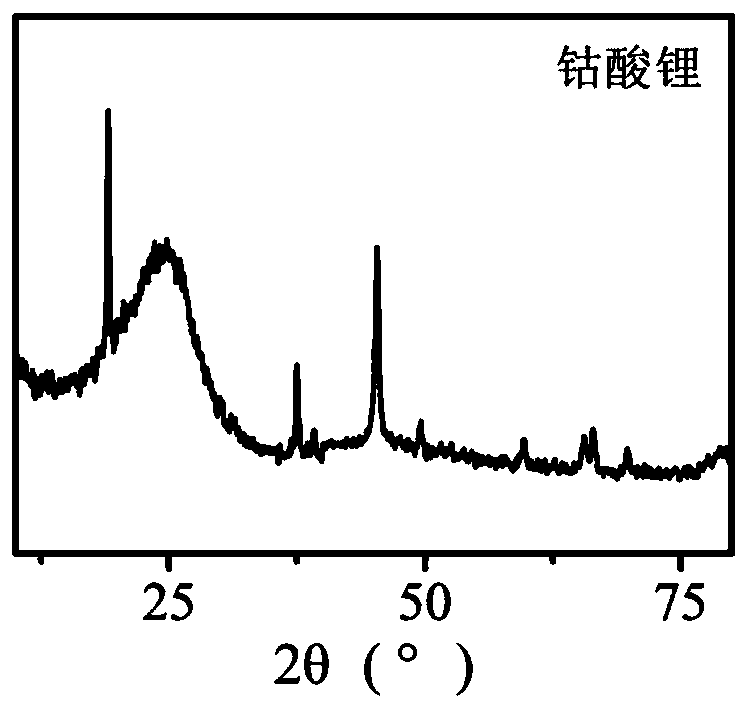

[0036] (2) Molten alkali electrolysis: Mix and grind KOH and LiOH at a mass ratio of 3:1, heat to 300 °C and melt, add pre-reduced waste lithium cobaltate powder, and the mass ratio of positive elect...

Embodiment 2

[0043]Example 2 Prepare the regenerated high-quality lithium manganate cathode material by one-step electrolysis in the mixed molten alkali system of KOH and LiOH with the lithium manganate cathode material of the waste lithium ion battery treated in the pre-reduction atmosphere, such as figure 1 As shown, the specific implementation method is:

[0044] (1) Pretreatment of waste lithium-ion battery positive electrode materials: Disassemble the waste lithium manganate battery after discharge treatment, put it into a reduction tube furnace, pass in argon-hydrogen mixed gas, and control H 2 Velocity is 50 m 3 / h, control the flow rate of Ar to 50 m 3 / h, after heating up to 200°C and keeping it warm for 2 h, scrape off the treated waste lithium manganate powder from the aluminum foil;

[0045] (2) Molten alkali electrolysis: KOH and LiOH are mixed and ground at a mass ratio of 3:1, heated to 300 °C and melted, and the waste lithium manganate powder after pre-reduction treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com