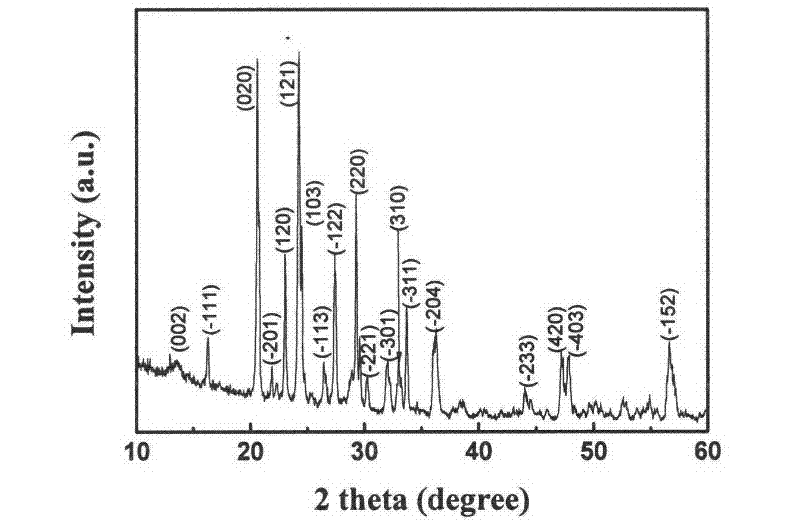

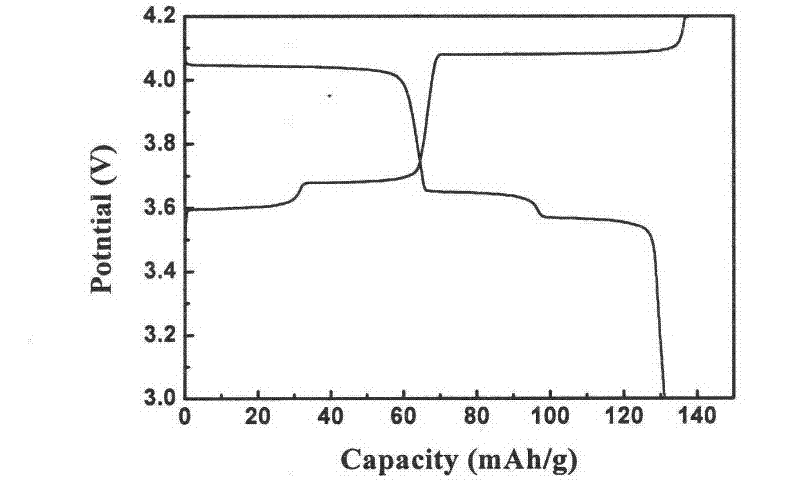

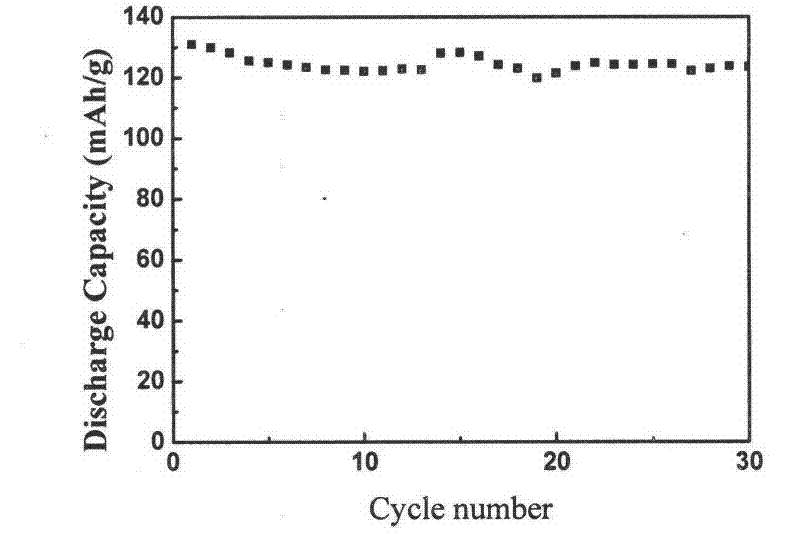

Rheological phase method for modifying lithium ion cathode material Li3V2(PO4)3 by adopting PEG composite system

A positive electrode material and rheological phase technology, applied in the field of rheological phase, to achieve high charge and discharge capacity, good cycle performance, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Take 3.0313g vanadium pentoxide (V 2 o 5 ) in the beaker, adding mass percentage concentration is 30% hydrogen peroxide 30ml, stirs with glass rod, forms vanadium pentoxide hydrogel (V 2 o 5 ·nH 2 O);

[0017] (2) Add 6.603g of diammonium hydrogen phosphate, 2.098g of lithium hydroxide monohydrate and 0.1g of high molecular weight PEG10000 to the product obtained in step (1), and ultrasonically vibrate for 8 minutes;

[0018] (3) Use a 5ml pipette to measure 1.5ml of analytically pure small molecular weight PEG200 and add it to the product obtained in step (2), transfer it to a round bottom flask, and evaporate to dryness on a rotary evaporator at 45°C for 1 hour, and then Dry in a vacuum drying oven at 80°C for 4 hours; take it out, grind it into powder with an agate mortar, take the powder in a porcelain boat, and sinter it in a vacuum sintering furnace at 700°C under the protection of high-purity argon for 15 hours. After cooling to room temperature, the pro...

Embodiment 2

[0022] (1) Take 3.0313g vanadium pentoxide (V 2 o 5 ) in the beaker, adding mass percentage concentration is 30% hydrogen peroxide 30ml, stirs with glass rod, forms vanadium pentoxide hydrogel (V 2 o 5 ·nH 2 O);

[0023] (2) Add 6.603g of diammonium hydrogen phosphate, 2.098g of lithium hydroxide monohydrate and 0.3g of high molecular weight PEG20000 to the product obtained in step (1), and ultrasonically vibrate for 8 minutes;

[0024] (3) Use a 5ml pipette to measure 2ml of analytically pure small molecular weight PEG400 and add it to the product obtained in step (2), transfer it to a round-bottomed flask, and evaporate to dryness on a rotary evaporator at 50°C for 0.5 hour. Dry in a vacuum drying oven at 120°C for 4 hours; take it out, grind it into powder with an agate mortar, take the powder in a porcelain boat, sinter in a vacuum sintering furnace at 850°C under the protection of high-purity argon for 20 hours, and naturally Cooling to room temperature yields Li 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com