Multi-element lithium-rich manganese-based positive electrode material and preparation method and application thereof

A lithium-rich manganese-based, cathode material technology, applied in the field of electrochemistry, can solve problems such as complex preparation methods, achieve the effects of simple preparation methods, conducive to large-scale production, and avoid lithium loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

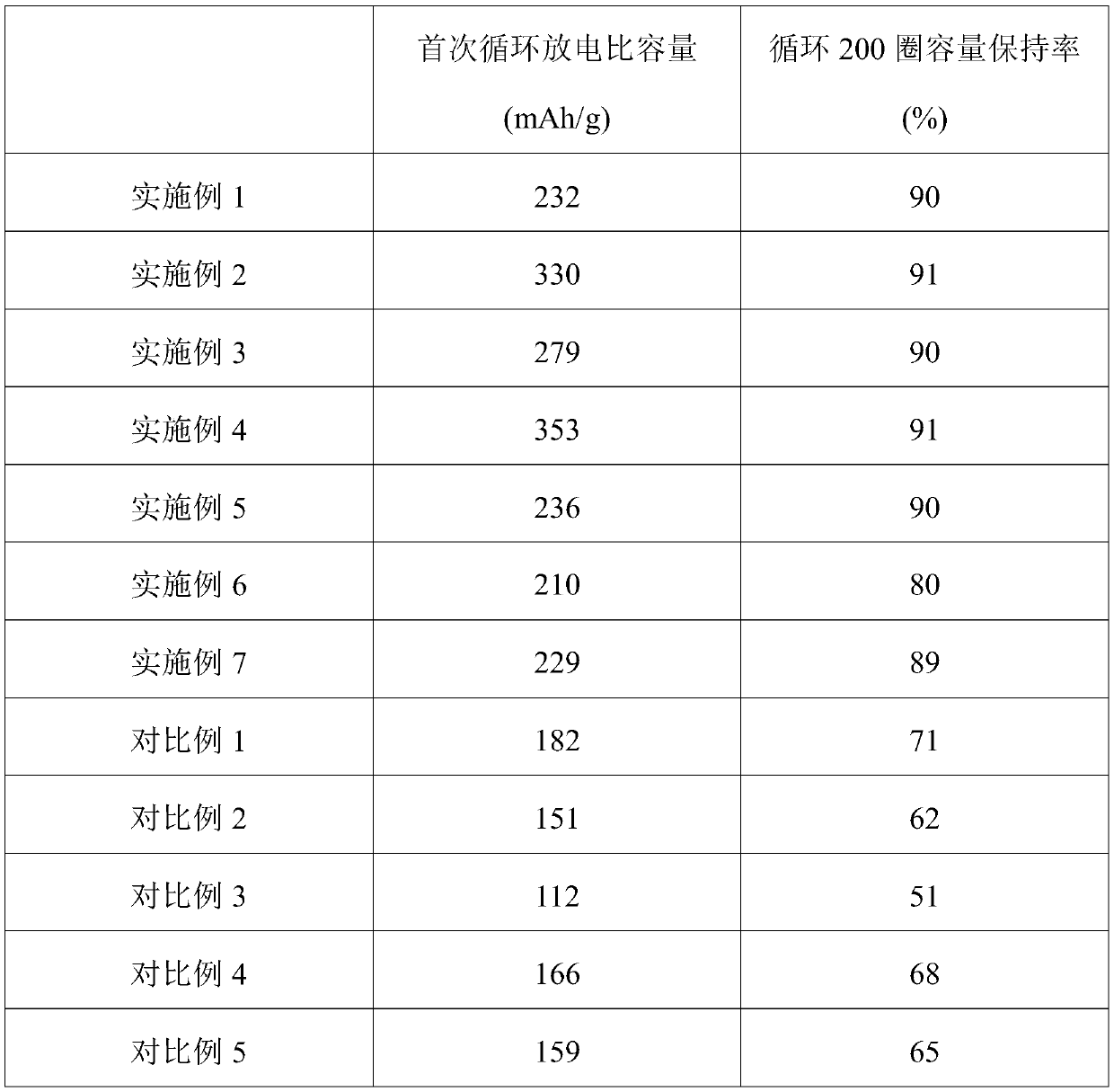

Examples

Embodiment 1

[0052] This embodiment provides a multi-element lithium-rich manganese-based positive electrode material Li 2 mn 0.5 Ti 0.1 V 0.2 Mo 0.1 o 2 The preparation method of F, described preparation method comprises the steps:

[0053] Mix lithium hydroxide, manganese oxide, titanium dioxide, vanadium pentoxide, molybdenum trioxide and lithium fluoride according to the stoichiometric ratio, and then ball mill the mixture for 80 hours under an argon atmosphere with a ball-to-material ratio of 5:1 to obtain the multi-component rich Lithium-manganese-based cathode materials.

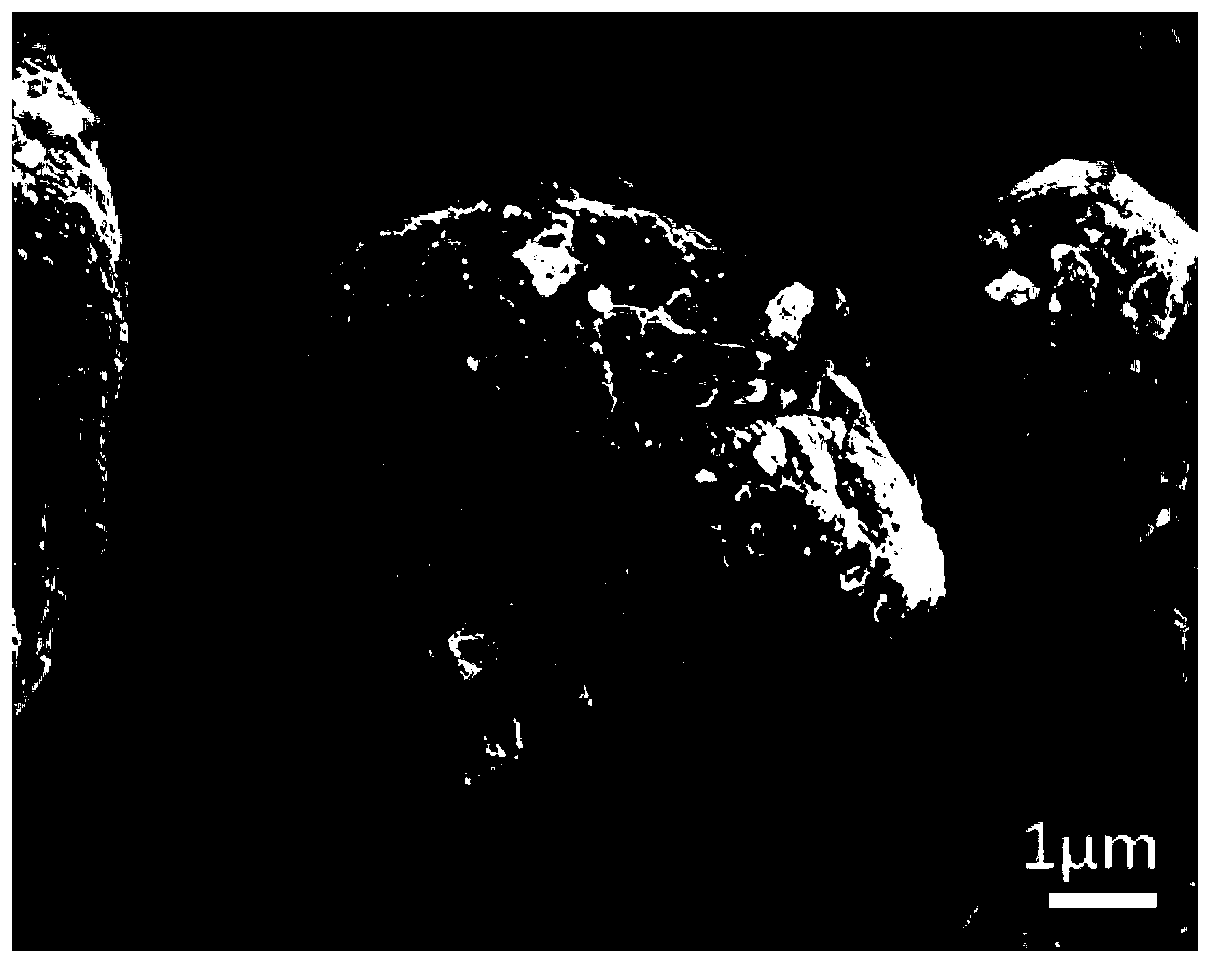

[0054] The scanning electron microscope image of the obtained multivariate lithium-rich manganese-based cathode material is as follows figure 1 As shown, it can be seen from the figure that the obtained positive electrode material is micron-sized spherical particles with regular shape and relatively dense particles.

Embodiment 2

[0056] This embodiment provides a multi-element lithium-rich manganese-based positive electrode material Li 2 mn 0.75 Zr 0.1 V 0.1 W 0.1 o 2 The preparation method of F, described preparation method comprises the steps:

[0057] Mix lithium oxide, manganese carbonate, zirconia, vanadium trioxide, tungsten trioxide and lithium fluoride according to the stoichiometric ratio, and then ball mill the mixture for 30 hours under a nitrogen atmosphere with a ball-to-material ratio of 10:1 to obtain the multi-element lithium-rich Manganese-based cathode materials.

Embodiment 3

[0059] This embodiment provides a multi-element lithium-rich manganese-based positive electrode material Li 2 mn 0.675 Ti 0.05 Nb 0.05 Cr 0.2 o 2 The preparation method of F, described preparation method comprises the steps:

[0060] Lithium carbonate, manganese acetate, tetrabutyl titanate, niobium trioxide, chromium trioxide and lithium fluoride were mixed according to the stoichiometric ratio, and then the mixture was ball milled for 5 h under a helium atmosphere with a ball-to-material ratio of 30:1 to obtain the obtained The multi-element lithium-rich manganese-based cathode material is described.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com