P-doped glass powder, preparation method of P-doped glass powder, and method for preparing positive silver slurry for solar battery from P-doped glass powder

A technology for solar cells and phosphorus glass, which is applied in the field of preparing front-side silver paste, can solve the problems of low photoelectric conversion efficiency and low phosphorus doping efficiency of crystalline silicon solar cells, and achieve high photoelectric conversion efficiency and high-efficiency doping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: In this embodiment, a phosphorus-doped glass powder consists of 1-10 parts by weight of PbO, 15-30 parts of Bi 2 o 3 , 15 to 25 parts of SiO 2 , 10 to 35 parts of TeO 2 , 5 to 15 parts of ZnO, 3 to 5 parts of MgO, 5 to 15 parts of B 2 o 3 Prepared with 1-10 parts of phosphorus source.

specific Embodiment approach 2

[0020] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the phosphorus source is phosphorus pentoxide, diammonium hydrogen phosphate, ammonium dihydrogen phosphate, calcium hydrogen phosphate, calcium phosphate, calcium pyrophosphate, phosphoric acid Potassium dihydrogen phosphate, dipotassium hydrogen phosphate, sodium acid pyrophosphate, sodium dihydrogen phosphate, disodium hydrogen phosphate, sodium phosphate, sodium pyrophosphate, calcium dihydrogen phosphate, phosphoric acid, potassium dihydrogen phosphate, dipotassium hydrogen phosphate, acid Sodium pyrophosphate, trimetapyrophosphate, potassium dihydrogen phosphate, potassium pyrophosphate, potassium tripolyphosphate, sodium metaphosphate, calcium dihydrogen phosphate, calcium dihydrogen phosphate, potassium dihydrogen phosphate and dipotassium hydrogen phosphate species or a mixture of several of them. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: the present embodiment is: a kind of preparation method of phosphorus-doped glass powder is finished according to the following steps:

[0022] 1. Weigh 1 to 10 parts of PbO and 15 to 30 parts of Bi by weight 2 o 3 , 15 to 25 parts of SiO 2 , 10 to 35 parts of TeO 2 , 5 to 15 parts of ZnO, 3 to 5 parts of MgO, 5 to 15 parts of B 2 o 3 and 1-10 parts of phosphorus source;

[0023] 2. Take 1 to 10 parts of PbO, 15 to 30 parts of Bi 2 o 3 , 15 to 25 parts of SiO 2 , 10 to 35 parts of TeO 2 , 5 to 15 parts of ZnO, 3 to 5 parts of MgO and 5 to 15 parts of B 2 o 3 Mix evenly to obtain mixed powder;

[0024] 3. Put the mixed powder in an aluminum crucible, then place the aluminum crucible in a high-temperature electric furnace with a temperature of 1200 ° C to 1400 ° C for 20 min to 60 min, and then quench the aluminum crucible in distilled water to room temperature to obtain coarse glass powder; Coarse glass powder is pulverized by a jet...

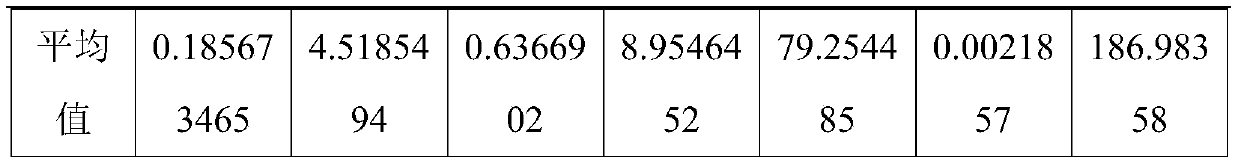

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com