Polyimide foam plastic and its preparation method

A technology of foam plastics and polyimide, which is applied in the direction of adhesives, etc., can solve the problems of poor overall uniformity of polyimide foam plastic foam and wide distribution of foam pore size, so as to achieve unaffected heat resistance and uniformity of cells Good, the effect of improving mechanical properties or flexibility properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention discloses a preparation method of polyimide foam plastics, comprising the following steps:

[0042] 1a) Mix dianhydride and lower aliphatic alcohol and carry out esterification reaction to obtain diacid diester solution;

[0043] 1b) mixing the diacid diester solution obtained in step 1a) with polymerized monomer amine and polyamic acid powder to obtain a mixed solution;

[0044] 1c) Concentrating the mixed liquid obtained in the step 1b) followed by foaming and thermal imidization in order to obtain polyimide foam plastics.

[0045] In the present invention, in the preparation process of polyimide foam obtained by polymerization of dianhydride and diamine, polyamic acid powder is added in the preparation process of its foaming precursor, and polyamic acid powder is used as a foam nucleating agent to improve the polyimide foam. Cell uniformity of imide foam.

[0046] In the embodiment of the present invention, dianhydride and lower aliphatic alcohol are ...

Embodiment 1

[0124] Add 64.44g (0.20mol) of 4,4'-benzophenonetetracarboxylic dianhydride to 126g of methanol, heat to reflux for esterification reaction, and continue the reaction for 1 hour until the system is clear to obtain a diacid diester solution.

[0125] The temperature of the reaction system was lowered to room temperature, and 40.05 g (0.20 mol) of 4,4'-diaminodiphenyl ether was added, and the stirring reaction was continued for 1 hour to form a uniform mixed solution.

[0126] Concentrate the above mixed solution, then spread the obtained solid powder on an aluminum plate to form a 2mm powder layer, transfer it to an oven, and foam it at 160°C for 60 minutes to obtain a foamed polyimide intermediate brittle material, This brittle foam was pulverized to obtain polyamic acid powder.

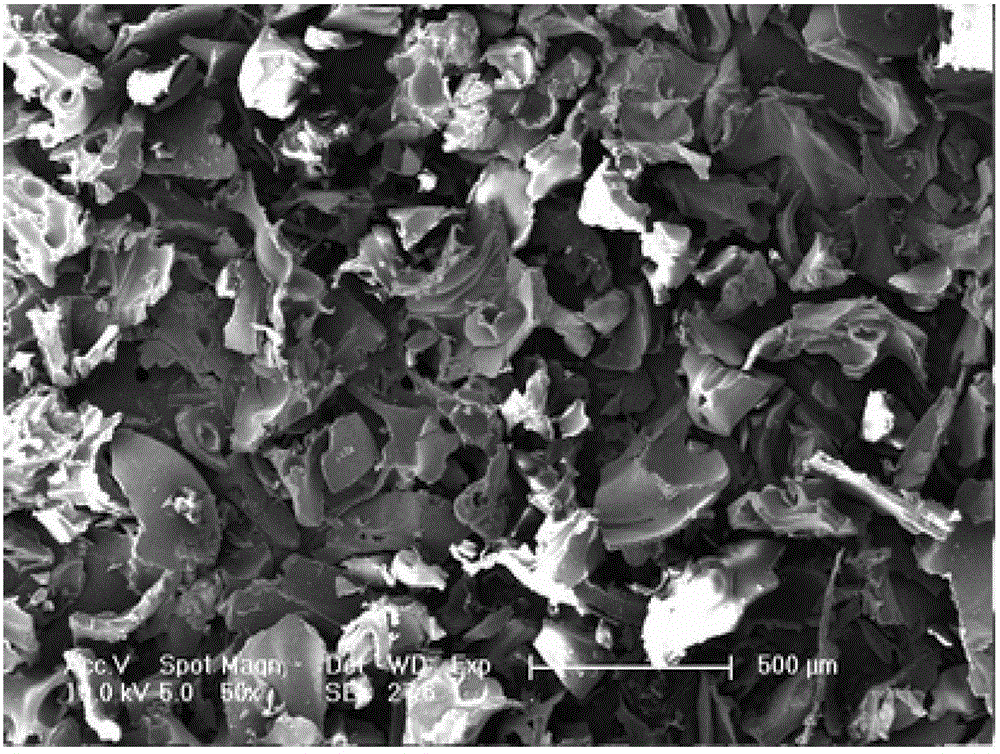

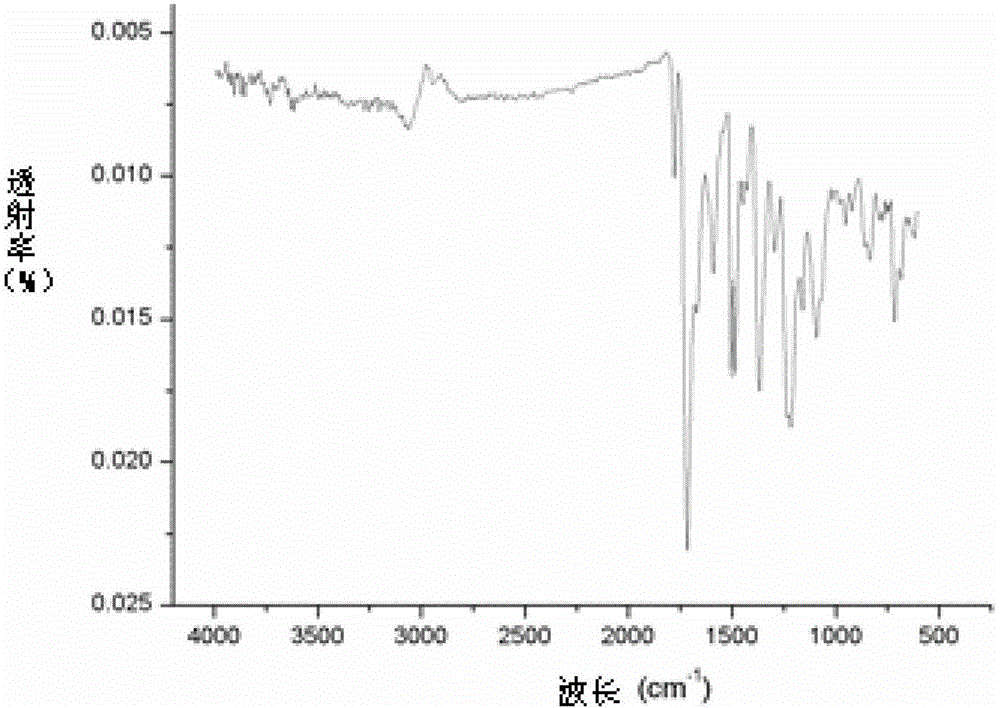

[0127] Electron microscope analysis and infrared spectrum analysis are carried out to gained powder, and analysis result is as follows: figure 1 with figure 2 as shown, figure 1 It is an electron...

Embodiment 2

[0129] Add 29.42g (0.10mol) of 4,4'-biphenyltetracarboxylic dianhydride into 63g of methanol, heat to reflux for esterification reaction, and continue the reaction for 1 hour until the system is clear to obtain a diacid diester solution.

[0130] The temperature of the reaction system was lowered to room temperature, 20.02 g (0.10 mol) of 3,4'-diaminodiphenyl ether was added, and the stirring reaction was continued for 1 hour to form a uniform mixed solution.

[0131] Concentrate the above mixed solution, then spread the obtained solid powder on an aluminum plate to form a 2mm powder layer, transfer it to an oven, and foam it at 160°C for 60 minutes to obtain a foamed polyimide intermediate brittle material, This brittle foam was pulverized to obtain polyamic acid powder.

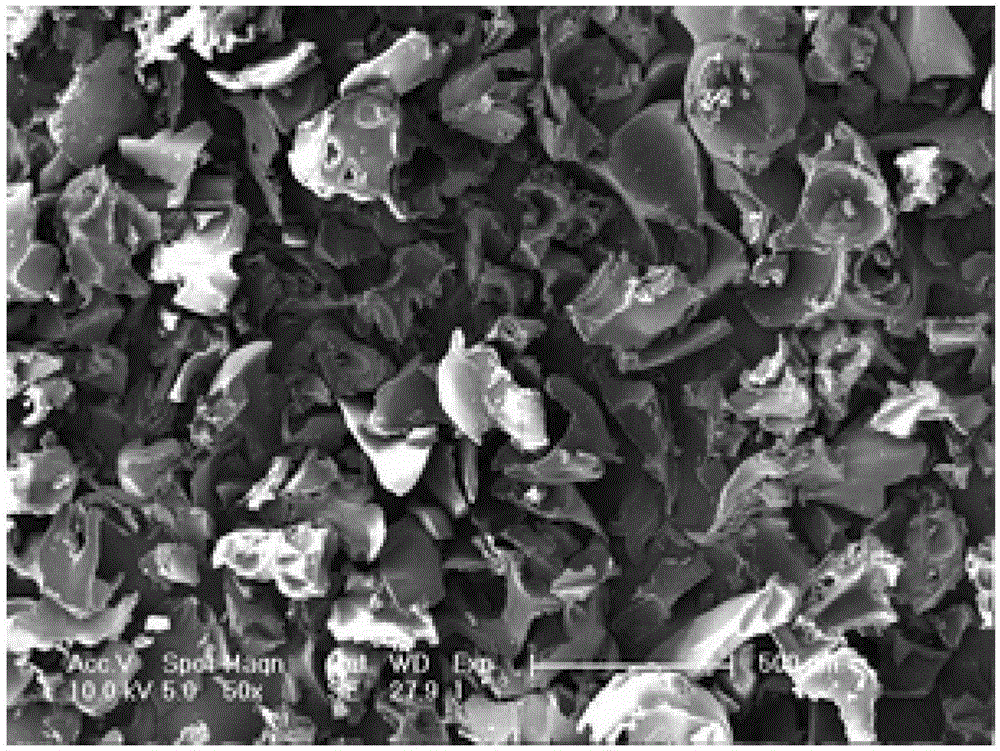

[0132] Electron microscope analysis and infrared spectrum analysis are carried out to gained powder, and analysis result is as follows: image 3 with Figure 4 as shown, image 3 It is an electron microg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com