Composite bond cbn grinding wheel for stainless steel medullary cavity reamer and its application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

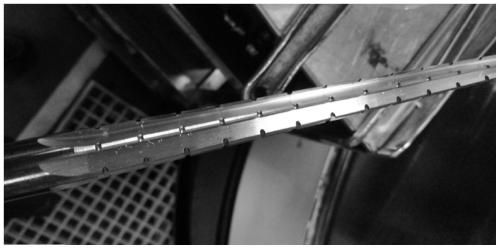

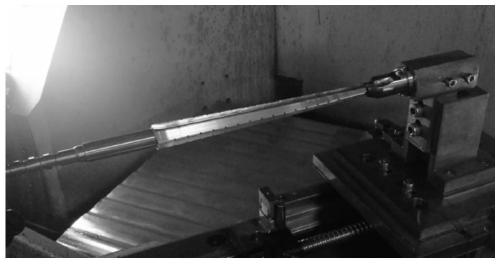

Image

Examples

Embodiment 1

[0043] Embodiment one prepares composite bond CBN emery wheel, comprises the following steps:

[0044] 1. Preparation of alloy powder:

[0045] The metal powder raw materials in the following weight percentages: 55% copper powder, 40% tin powder, and 5% silver powder are mixed and ball milled, and passed through a 320-mesh standard sieve to obtain alloy powder.

[0046] 2. Preparation of matrix mixture:

[0047] The powder raw material of following volume percentage: Modified polyimide resin powder (brand PI-KF-1, commercially available) 35%, copper powder 52%, tin powder 10%, silver powder 3% are placed in three-dimensional mixing machine and mix After 1 h, pass through a 320-mesh standard sieve to obtain a matrix mixture.

[0048] 3. Preparation of composite bond CBN grinding wheel:

[0049] (1) Mix 80% alloy powder and 20% modified polyimide resin powder (brand PI-KF-1, commercially available) in a three-dimensional mixer for 1 hour, then pass through 320 mesh Standard ...

Embodiment 2

[0058] Embodiment 2 Preparation of composite bond CBN grinding wheel, the process is the same as that of Embodiment 1, and the specific steps are:

[0059] 1. Preparation of alloy powder:

[0060] The metal powder raw materials in the following weight percentages: 50% copper powder, 40% tin powder, and 10% silver powder are mixed and ball milled, and passed through a 320-mesh standard sieve to obtain alloy powder.

[0061] 2. Preparation of matrix mixture:

[0062] Put the following powder raw materials in volume percentage: 31% modified polyimide resin powder, 56% copper powder, 11% tin powder, 2% silver powder in a three-dimensional mixer for 1 hour and then pass through a 320-mesh standard sieve to prepare Obtain the matrix mixture.

[0063] 3. Preparation of composite bond CBN grinding wheel:

[0064] (1) Put the alloy powder and resin powder with a volume percentage of 75% and 25% in a three-dimensional mixer for 1 hour, and then pass through a 320-mesh standard sieve ...

Embodiment 3

[0073] Embodiment 3 Preparation of composite bond CBN grinding wheel, the process is the same as that of Embodiment 1, and the specific steps are:

[0074] 1. Preparation of alloy powder:

[0075] The metal powder raw materials with the following weight percentages: 52% of copper powder, 41% of tin powder, and 7% of silver powder are mixed and ball milled, and passed through a 320-mesh standard sieve to obtain alloy powder.

[0076] 2. Preparation of matrix mixture:

[0077] Put the following powder raw materials in volume percentage: 38% of modified polyimide resin powder, 50% of copper powder, 10% of tin powder, and 2% of silver powder in a three-dimensional mixer for 1 hour and then pass through a 320-mesh standard sieve to prepare Obtain the matrix mixture.

[0078] 3. Preparation of composite bond CBN grinding wheel:

[0079] (1) Put the alloy powder and resin powder with a volume percentage of 70% and 30% in a three-dimensional mixer for 1 hour, and then pass through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com