Epoxy resin concrete material with anti-cracking property

A technology of epoxy resin and concrete, which is applied in the field of concrete, can solve the problems of unfavorable influence on the safety and durability of concrete structures, low compression resistance, flexural resistance and crack resistance, poor flexibility and impact resistance, etc., to achieve Accelerate the hardening speed, good water resistance, increase the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] An epoxy resin concrete material with crack resistance, comprising 65 parts of cement and 35 parts of adhesive, the adhesive includes the following components in percentage by weight: 80% denatured epoxy resin, 15% curing agent, Reactive diluent 5%;

[0051] Described curing agent is triethylamine;

[0052] Described reactive diluent is allyl glycidyl ether;

[0053] The preparation method of described modified epoxy resin specifically comprises the following steps:

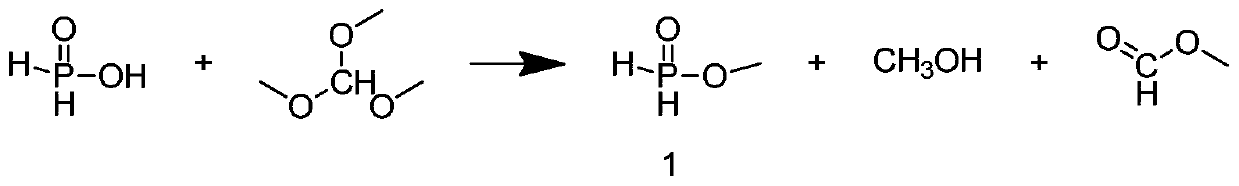

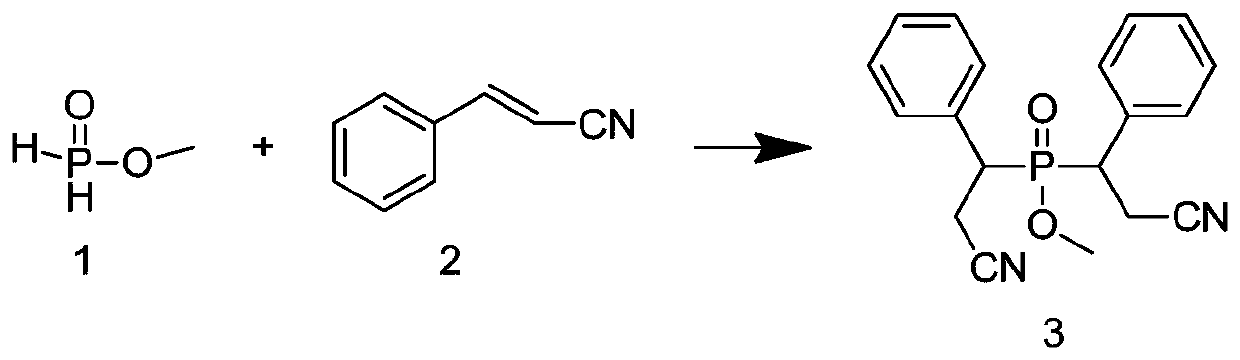

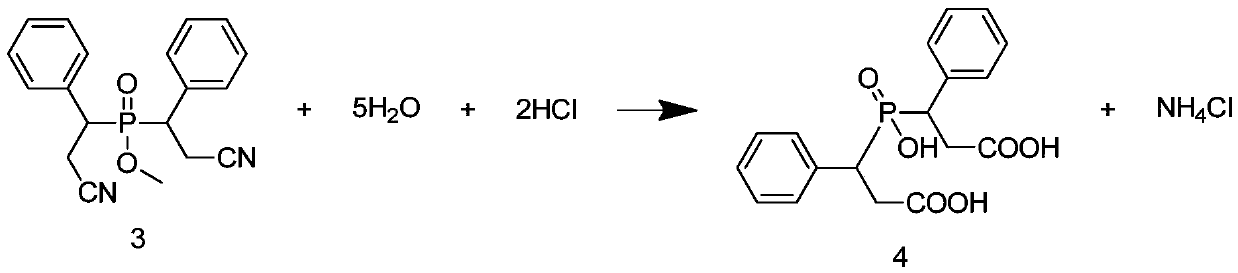

[0054] S1, the synthesis of methyl hypophosphite

[0055] The reaction formula is as follows:

[0056]

[0057] Commercially available 50% hypophosphorous acid was removed by rotary evaporation to obtain 95% hypophosphorous acid. Under ice-water bath, 200mol95% hypophosphorous acid and 210mol trimethyl formate were added to the reactor, and the temperature was raised after stirring for 10min. When the temperature was 35°C, the stirring reaction was continued for 3 hours, and methanol and methyl form...

Embodiment 2

[0071] An epoxy resin concrete material with crack resistance, comprising 85 parts of cement and 15 parts of adhesive, said adhesive includes the following components in percentage by weight: 90% denatured epoxy resin, 5% curing agent, Reactive diluent 5%;

[0072] Described curing agent is triethylamine;

[0073] Described reactive diluent is allyl glycidyl ether;

[0074] The preparation of described modified epoxy resin is with embodiment 1.

Embodiment 3

[0076] An epoxy resin concrete material with crack resistance, comprising 80 parts of cement and 20 parts of adhesive, said adhesive includes the following components in percentage by weight: denatured epoxy resin 85%, curing agent 8%, Reactive diluent 7%;

[0077] Described curing agent is triethylamine;

[0078] Described reactive diluent is allyl glycidyl ether;

[0079] The preparation of described modified epoxy resin is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com