Monolithic VOCs catalytic combustion catalyst, and preparation method thereof

A catalytic combustion, integrated technology, used in catalyst activation/preparation, combustion methods, physical/chemical process catalysts, etc. Effect of implementation, flexibility, simple process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

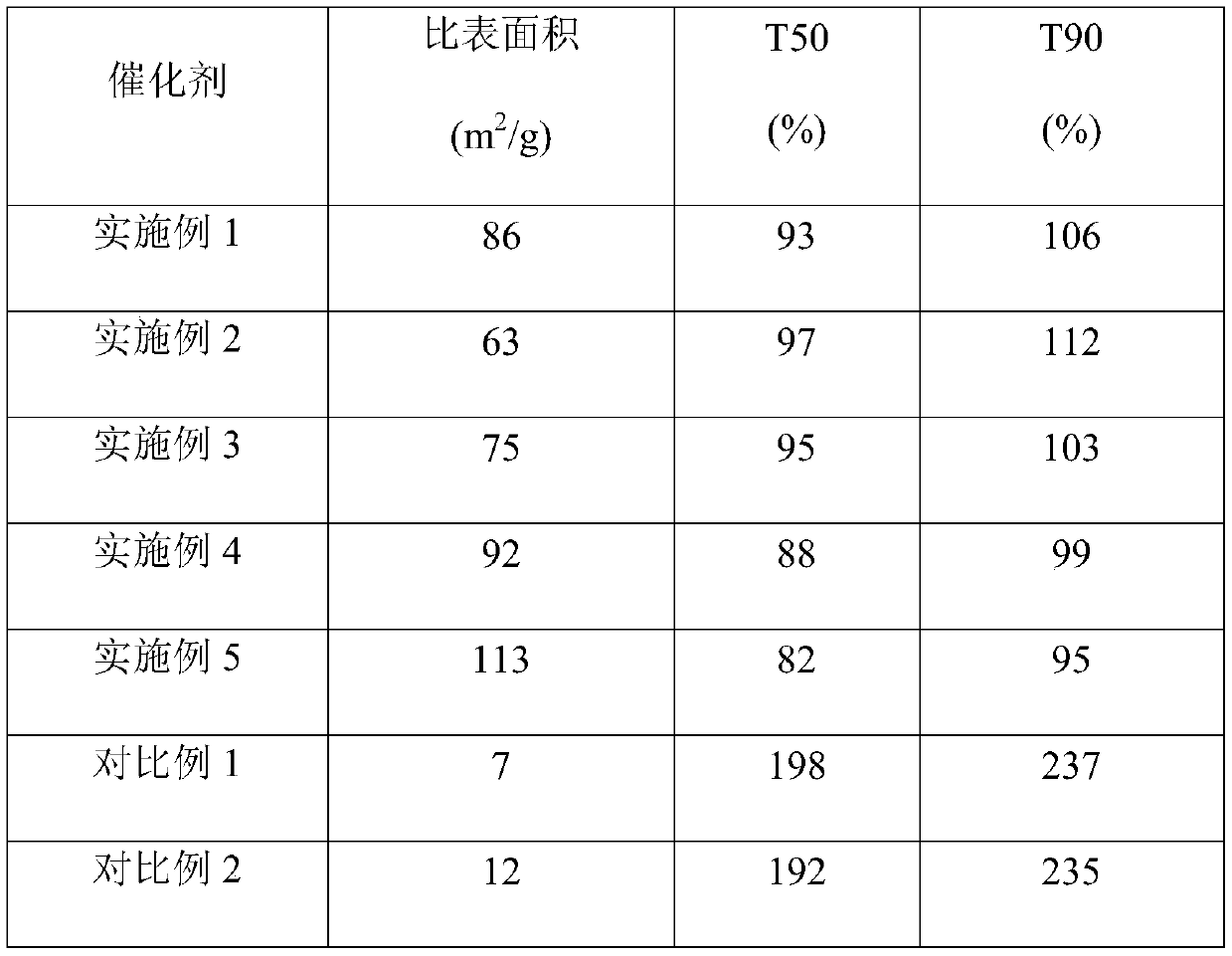

Embodiment 1

[0061] Cut the polyester fiber felt according to the dimensions of 15cm in length, 10cm in width, and 2cm in thickness, put it into the rotary furnace and feed in 2L / min of air, then raise the temperature at 2°C / min to 230°C for 8 hours, cool down to room temperature and leave material; put the obtained fiber felt into an atmosphere furnace, heat up to 800°C for 2 hours under a nitrogen atmosphere at 2°C / min, and then discharge the material after cooling down to room temperature; put the obtained carbonized fiber felt into a rotary furnace, and feed 200mL / min steam, heated to 600°C for 2 hours at 2°C / min, and discharged after cooling down to room temperature; Copper sulfate, manganese sulfate, cobalt sulfate, and cerium sulfate were respectively adjusted according to 5% and 5% of the mass of the activated carbon fiber felt matrix. %, 3%, and 3% are mixed and dissolved in water and impregnated into carbon fiber felt, then placed in a blast drying oven at 100°C to dry and take w...

Embodiment 2

[0063] Cut the polyester fiber felt according to the dimensions of 15cm in length, 10cm in width, and 2cm in thickness, put it into the rotary furnace and feed in 2L / min of air, then raise the temperature at 2°C / min to 230°C for 8 hours, cool down to room temperature and leave material; put the obtained fiber felt into an atmosphere furnace, heat up to 800°C for 2 hours under a nitrogen atmosphere at 2°C / min, and then discharge the material after cooling down to room temperature; put the obtained carbonized fiber felt into a rotary furnace, and feed 200mL / min carbon dioxide gas, heat up to 600°C at 2°C / min for activation for 2 hours, and discharge after cooling down to room temperature; copper sulfate, manganese sulfate, cobalt sulfate, and cerium sulfate are respectively 5% and 8% of the mass of the activated carbon fiber felt matrix , 3%, and 3% are mixed and dissolved in water and impregnated into carbon fiber felt, then put into a blast drying oven at 100°C to dry and take...

Embodiment 3

[0065] Cut the pitch-based fiber mat according to the size specifications of 15cm in length, 10cm in width and 2cm in thickness, put it into the rotary kiln and pass in 2L / min of air, then raise the temperature to 270°C at 2°C / min and react for 4 hours, cool down to room temperature and leave material; put the obtained fiber felt into an atmosphere furnace, heat up to 800°C for 2 hours under a nitrogen atmosphere at 2°C / min, and then discharge the material after cooling down to room temperature; put the obtained carbonized fiber felt into a rotary furnace, and feed 200mL / min steam, heated to 600°C for 2 hours at 2°C / min, and discharged after cooling down to room temperature; Copper sulfate, manganese sulfate, cobalt sulfate, and cerium sulfate were respectively adjusted according to 5% and 5% of the mass of the activated carbon fiber felt matrix. %, 3%, and 3% are mixed and dissolved in water and impregnated into carbon fiber felt, then placed in a blast drying oven at 100°C t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com