Method for rapidly preparing graphite phase carbon nitride nanorods without template

A graphite-phase carbon nitride and nanorod technology, which is applied in chemical instruments and methods, inorganic chemistry, nanotechnology, etc., can solve the problems of rapid acquisition, popularization and application of graphite-phase carbon nitride nanorods, increased environmental treatment costs, and environmental pollution. Friendly and other issues, to achieve the effect of high practical value, reduced recombination rate, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Put 10g of melamine into the lining of a 100mL hydrothermal kettle, add 70mL of 0.5mol / L acetic acid solution, and after ultrasonic dispersion for 30min, heat it in water at 180°C for 12h; mix the prepared self-assembled melamine with 0.2g of carbon fiber, put Put the crucible into a quartz crucible; then place the crucible in the resonant cavity of an industrial high-energy microwave oven and evacuate it to 7kPa, set the microwave power to 4kW, and start to keep warm after the temperature reaches 580°C, turn off the microwave oven after 10min, and let the reaction system cool down with the furnace The samples were taken out after reaching room temperature. It can be seen that there is a large amount of light yellow powder in the crucible, that is, graphite phase carbon nitride nanorods.

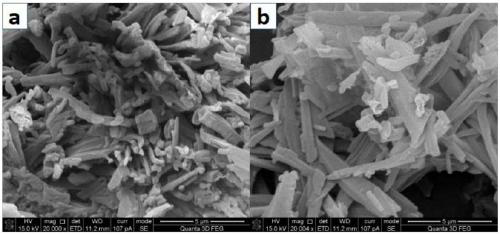

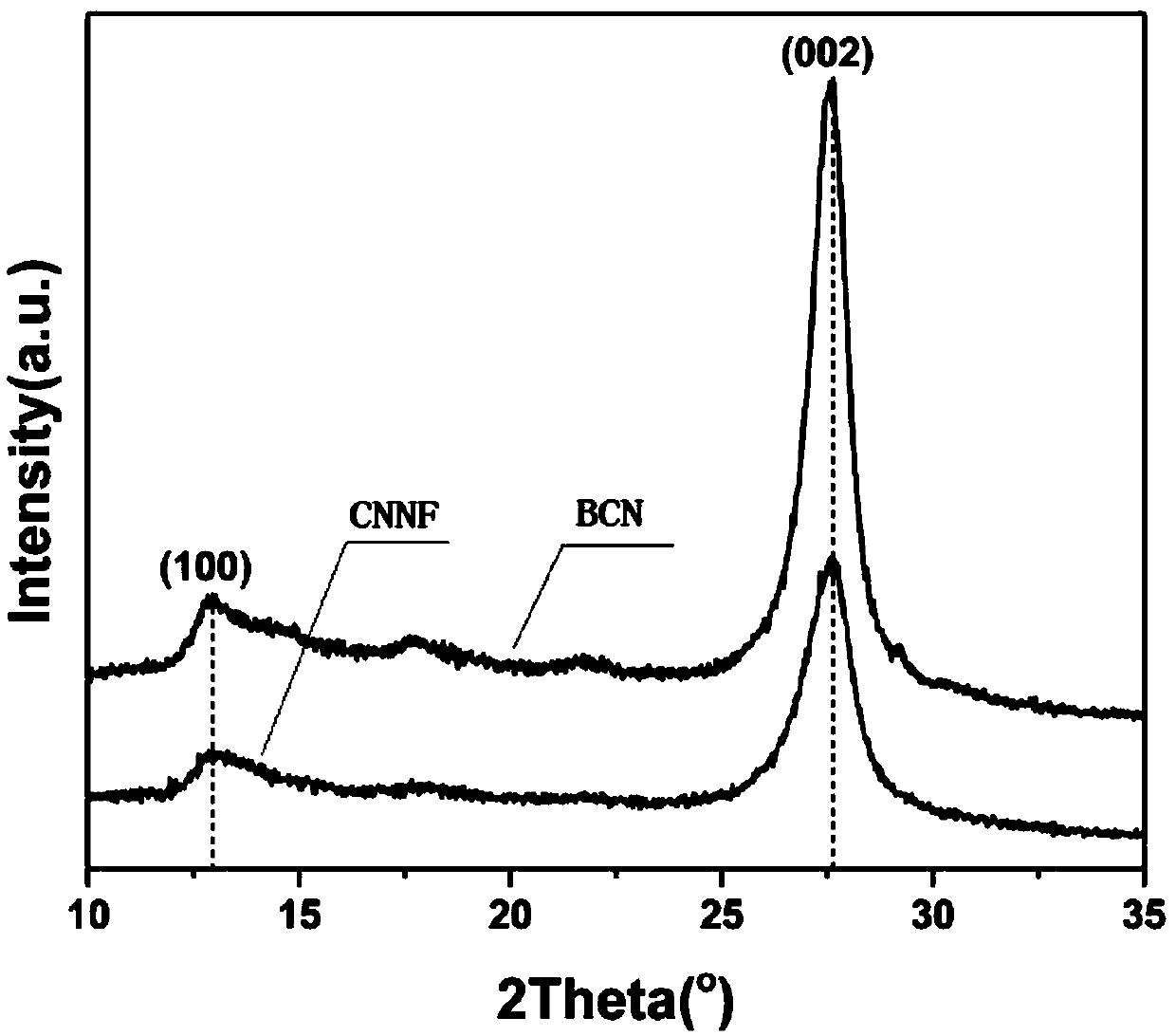

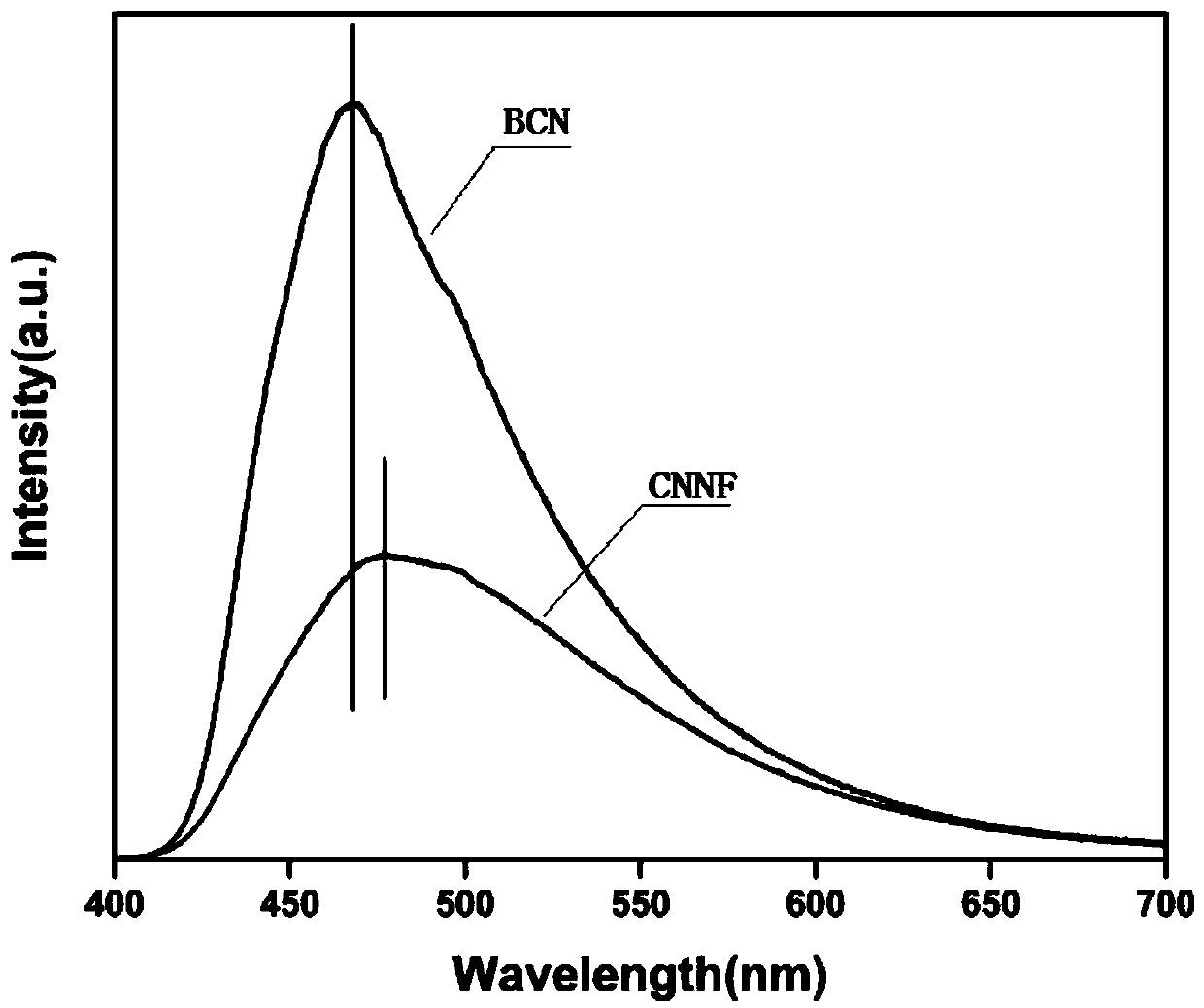

[0036] figure 1 The SEM image of the obtained carbon nitride nanorods shows that the length of the nanorods is about 5 μm, the diameter is about 300 nm, and the aspect ratio is about...

Embodiment 2

[0041] Put 10g of melamine into the lining of a 100mL hydrothermal kettle, add 70mL of 1.0mol / L acetic acid solution, mix ultrasonically for 30min, and heat it in water at 150°C for 12h; mix the prepared self-assembled melamine with 0.5g of carbon fiber, put it in In a quartz crucible; then place the crucible in the resonant cavity of an industrial high-energy microwave oven and evacuate it to 7kPa, set the microwave power to 4kW, keep warm after the temperature reaches 580°C, turn off the microwave oven after 10min, and let the reaction system cool down to room temperature with the furnace Then remove the sample. It can be seen that there are a large amount of light yellow powder in the crucible, that is, graphite phase carbon nitride nanorods, with an aspect ratio of 18 and a specific surface area of 154.8m 2 / g.

Embodiment 3

[0043] Put 10g of melamine into the lining of a 100mL hydrothermal kettle, add 70mL of 2.0mol / L acetic acid solution, mix ultrasonically for 30min, and heat it in water at 120°C for 12h; mix the prepared self-assembled melamine with 0.1g of carbon fiber, put in In a quartz crucible; then place the crucible in the resonant cavity of an industrial high-energy microwave oven and evacuate it to 7kPa, set the microwave power to 4kW, keep warm after the temperature reaches 580°C, turn off the microwave oven after 10min, and let the reaction system cool down to room temperature with the furnace Then remove the sample. It can be seen that there is a large amount of light yellow powder in the crucible, that is, graphite phase carbon nitride nanorods, with an aspect ratio of 20 and a specific surface area of 176.3m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com