Preparation method of ether ester copolymerization type polycarboxylic acid water reducing agent capable of improving rheological behavior

A rheological characteristic and copolymerization technology, which is applied in the field of ether ester copolymerization polycarboxylate water reducer, can solve the problems of lower concrete anticorrosion ability and lower concrete strength, so as to prevent bleeding and segregation, improve dispersion and keep slump The effect of fall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

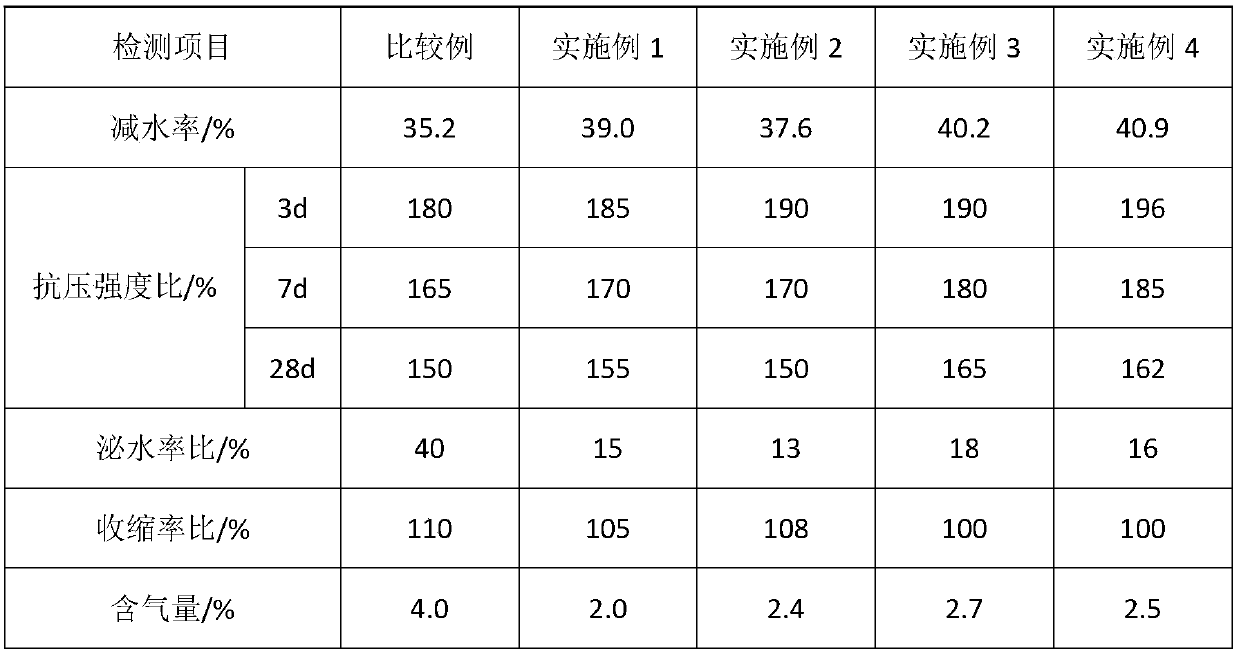

Examples

Embodiment 1

[0029] (1) Esterification reaction: 200.0g molecular weight is the methoxypolyethylene glycol of 4000, 52.2g methyl acrylate, 80.0gCH 3 (CH 2 ) 11 C 6 h 4 (OC 2 h 4 ) 20 Mix OH and 1.25g of polymerization inhibitor phenothiazine hydroquinone, under the protection of nitrogen, heat up to 40-60°C, then add 3.15g of catalyst 4-dimethylaminopyridine, heat up to 80-90°C, and react at constant temperature for 8h , down to room temperature after the reaction, to obtain the first mixture containing the esterification product and unreacted unsaturated acid and unsaturated carboxylic acid ester.

[0030] (2) Copolymerization reaction: get the first mixture that 100.0g step (1) makes, 200.0g molecular weight is the isopentenol polyoxyethylene ether of 5000, 16.0g methacrylic acid, 30.0g compound A (R 1 for -CH 2 , R 2 for CH 3 , n is 100) and 200.0g of deionized water are added to the reaction vessel and mixed, hydrogen peroxide aqueous solution (wherein hydrogen peroxide is 3....

Embodiment 2

[0033] (1) Transesterification reaction: 160.0g of methoxypolyethylene glycol with molecular weight of 3000, 65.9g of methyl methacrylate, 80.0g of CH 3 (CH 2 ) 7 C 6 h 4 (OC 2 h 4 ) 11 Mix OH and 1.02g of polymerization inhibitor hydroquinone, under the protection of nitrogen, heat up to 40-60°C, then add 3.25g of catalyst dibutyltin oxide, heat up to 90-100°C, keep warm for 6 hours, after the reaction Cool down to room temperature to obtain a first mixture of esterified product and unreacted methyl acrylate.

[0034](2) Copolymerization reaction: 200.0g of the first mixture prepared in step (1), 100.0g of isobutyl alcohol polyoxyethylene ether with a molecular weight of 4000, 14.4g of acrylic acid, 10.0g of compound A (R 1 for -CH 2 , R 2 is H, n is 20) and 300.0g deionized water are added to the reaction vessel and mixed, ammonium persulfate aqueous solution (wherein ammonium persulfate 3.15g, water 30.00g), dodecanethiol aqueous solution (wherein isopropanol 1.80g...

Embodiment 3

[0037] (1) Transesterification reaction: 100.0g of methoxypolyethylene glycol with a molecular weight of 1000, 57.0g of methyl methacrylate, 60.0g of CH 3 (CH 2 ) 8 C 6 h 4 (OC 2 h 4 ) 15 OH and 0.80g polymerization inhibitor diphenylamine were mixed, and under the protection of nitrogen, the temperature was raised to 40-60°C, and then 3.54g of catalyst sodium carbonate was added, the temperature was raised to 90-100°C, and the reaction was kept for 6 hours. After the reaction was completed, it was lowered to room temperature to obtain A first mixture of esterified product and unreacted methyl methacrylate.

[0038] (2) Copolymerization reaction: the first mixture prepared by 150.0g step (1), 150.0g molecular weight is 6000 isobutenol polyoxyethylene ether, 14.7g maleic anhydride, 20.0g compound A (R 1 for -CH 2 CH 2 , R 2 for CH 3 , n is 50) and 200.0g deionized water are added to the reaction vessel and mixed, hydrogen peroxide aqueous solution (wherein hydrogen p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com