Dodeca-tungstate crystal material with two-dimensional nano pore cavity structure and preparation method of dodeca-tungstate crystal material

A technology of two-dimensional nanometer and crystalline materials, applied in the fields of polycrystalline material growth, crystal growth, chemical instruments and methods, etc. High yield, simple and easy synthesis method, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] ①. Weigh 0.06g of sodium tungstate, 0.12g of tungstic acid, 0.08g of imidazole, 0.04g of ammonium chloride, and 0.03g of potassium chloride into a 50mL flask, add 18mL of distilled water, and place the flask on a magnetic stirrer to stir and mix After 20 minutes, a mixed solution was obtained.

[0023] ②. Transfer the uniformly mixed solution to a 25mL autoclave.

[0024] ③ Put the autoclave into an oven, heat it from room temperature to 160 °C at a rate of 1 °C / min, keep it at this temperature for 72 hours, and then lower it to room temperature at a rate of 0.2 °C / min to obtain a two-dimensional nanopore structure of dodecantungstate crystal material, the yield is about 72%.

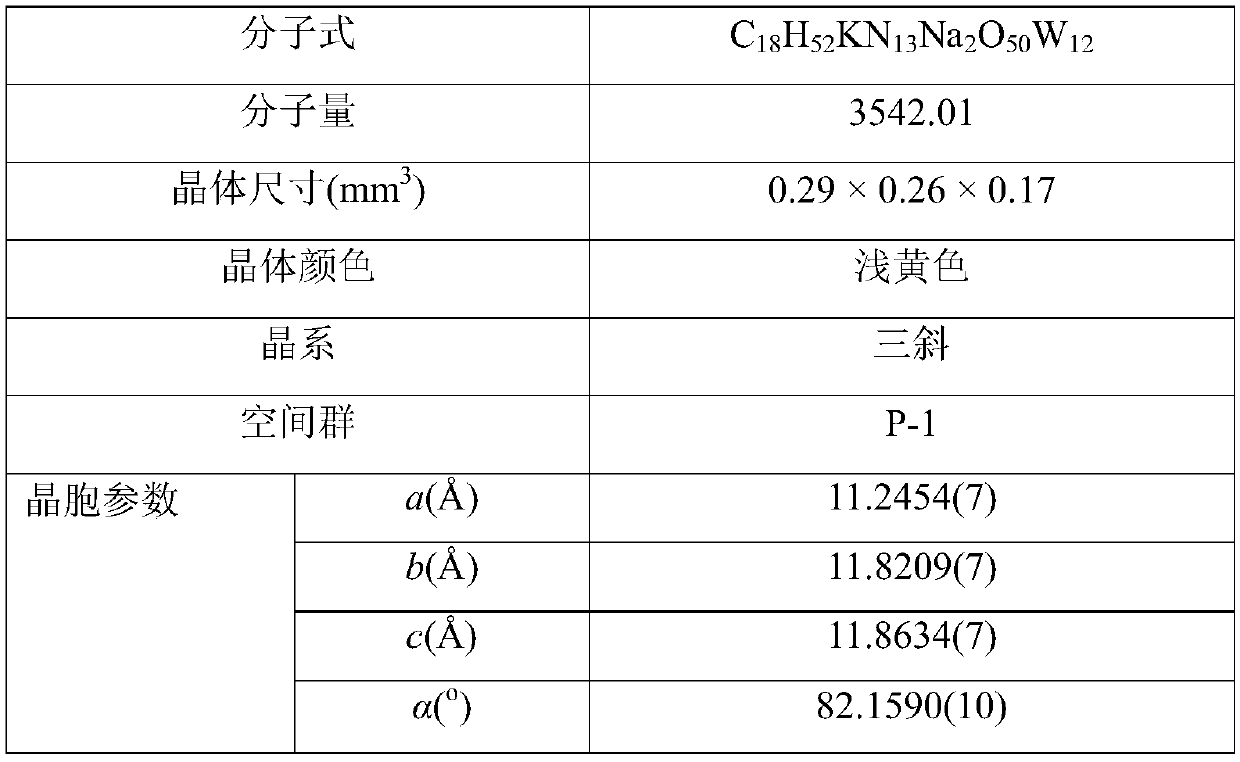

[0025] The crystal structure of the target product prepared in this embodiment was determined by a single crystal diffractometer, and the results were as follows:

[0026] Crystal data:

[0027]

[0028]

[0029] Crystal structure analysis:

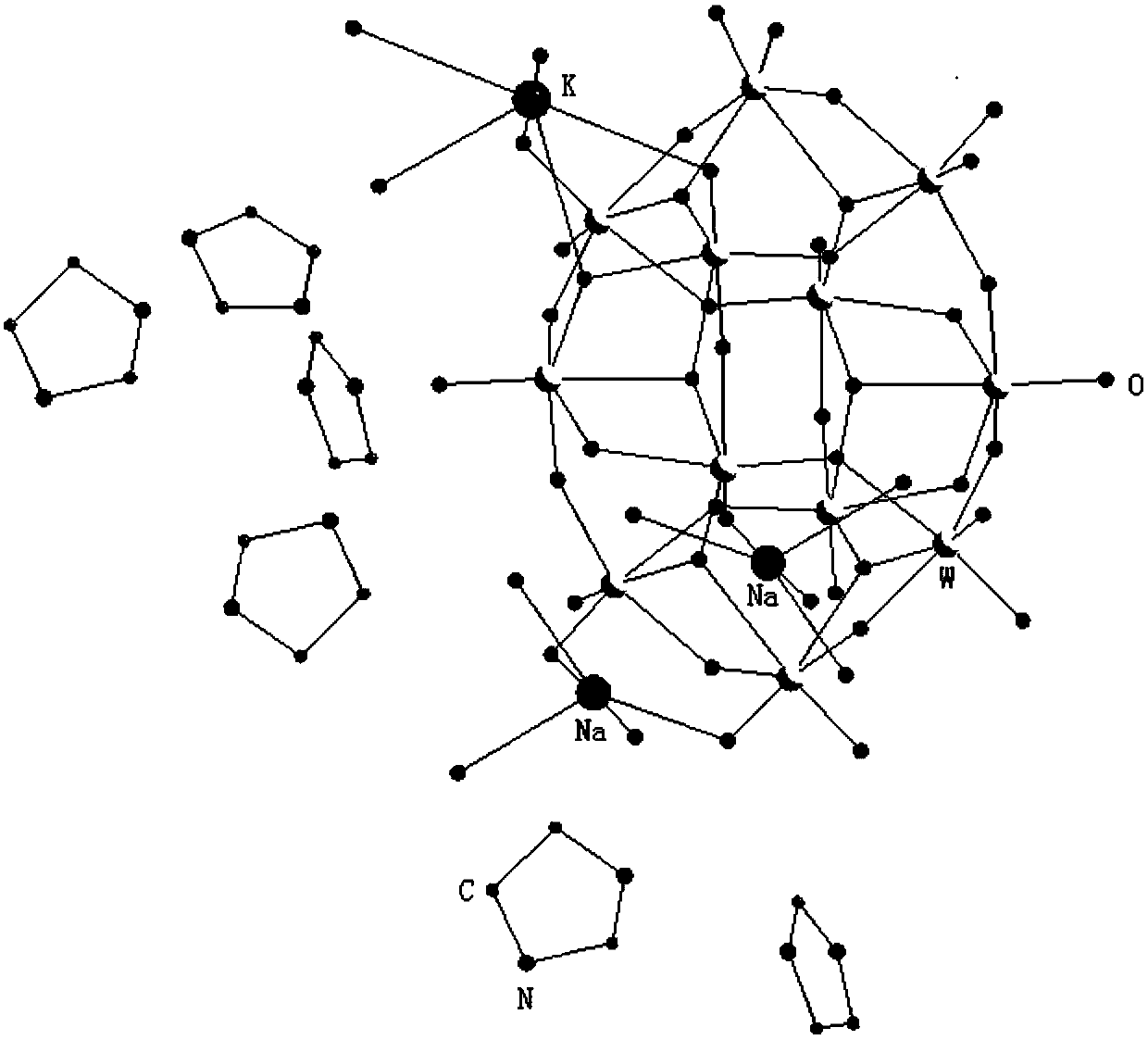

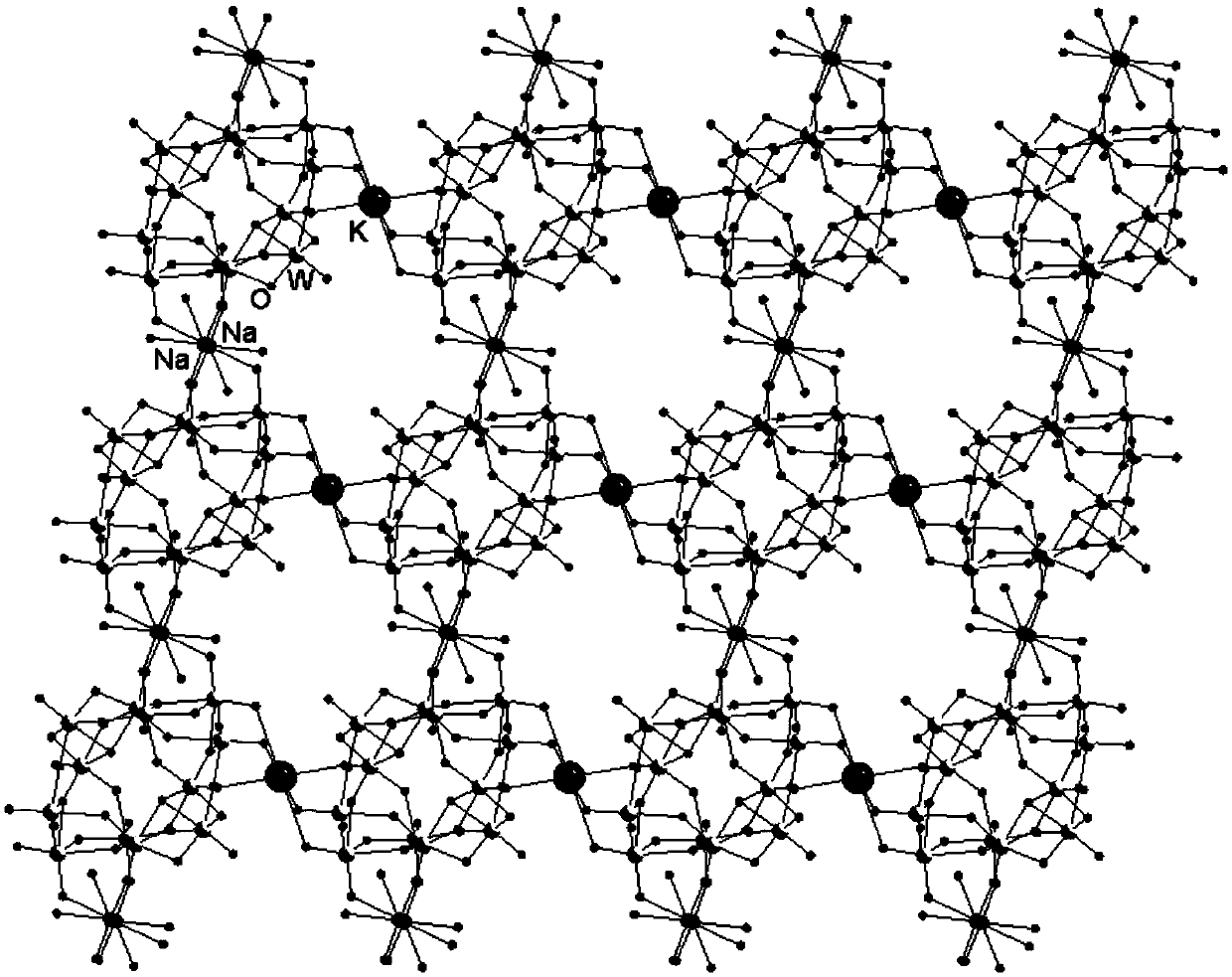

[0030] Please also refer to figure 1 , the ...

Embodiment 2

[0033] ①. Weigh 0.11g of sodium tungstate, 0.09g of tungstic acid, 0.07g of imidazole, 0.03g of ammonium chloride, and 0.04g of potassium chloride into a 50mL flask, add 20mL of distilled water, and place the flask on a magnetic stirrer to stir and mix After 20 minutes, a mixed solution was obtained.

[0034] ②. Transfer the uniformly mixed solution to a 25mL autoclave.

[0035] ③. Put the autoclave into an oven, heat it from room temperature to 160 °C at a rate of 1 °C / min, keep it at this temperature for 72 hours, and then lower it to room temperature at a rate of 0.26 °C / min to obtain the following: figure 1 with 2 The yield of the dodecungstate crystal material with a two-dimensional nano-cavity structure is about 73%.

Embodiment 3

[0037] ①. Weigh 0.06g of sodium tungstate, 0.12g of tungstic acid, 0.08g of imidazole, 0.04g of ammonium chloride, and 0.03g of potassium chloride into a 50mL flask, add 17mL of distilled water, and place the flask on a magnetic stirrer to stir and mix After 20 minutes, a mixed solution was obtained.

[0038] ②. Transfer the uniformly mixed solution to a 25mL autoclave.

[0039] ③. Put the autoclave into an oven, heat it from room temperature to 180 °C at a rate of 2 °C / min, keep it at this temperature for 48 hours, and then lower it to room temperature at a rate of 0.3 °C / min to obtain the following: figure 1 with 2 The yield of the dodecungungstate crystal material with a two-dimensional nano-cavity structure is about 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com