Anti-shock and anti-abrasion concrete for hydropower engineering and preparation method of anti-shock and anti-abrasion concrete

A technology for hydropower engineering and concrete, which is applied in the field of impact-resistant and wear-resistant concrete for hydropower engineering and its preparation, to achieve the effects of improving crack resistance, delaying stress concentration, and increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

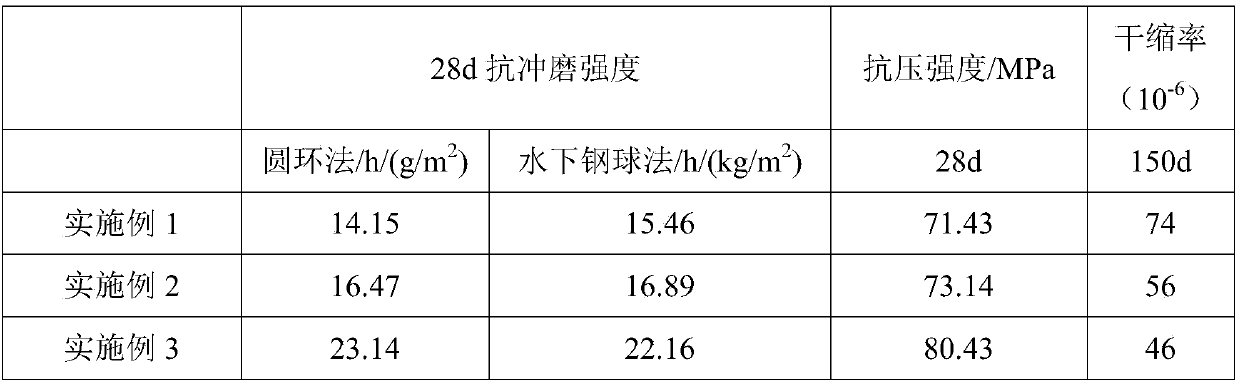

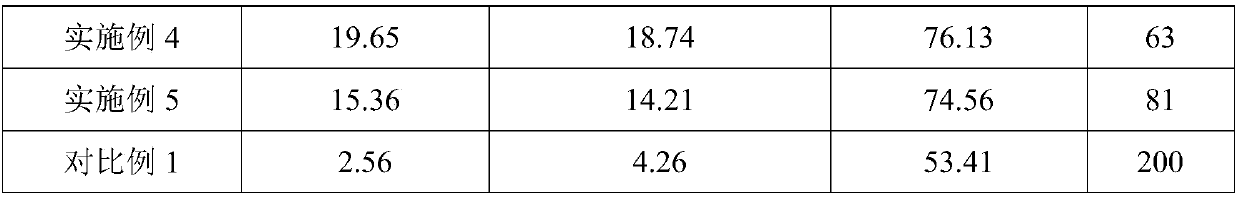

Examples

Embodiment 1

[0031] A concrete with high abrasion resistance for hydropower projects, comprising the following raw materials in parts by weight: 30 parts of yellow sand, 3 parts of finely ground slag powder, 15 parts of fly ash, 5 parts of silicon micropowder, 30 parts of cement, and 10 parts of potassium feldspar powder , 10 parts of medium sand, 2 parts of kaolin, 3 parts of anhydrite, 3 parts of polyvinyl alcohol fiber, 3 parts of high-strength imitation steel wire fiber, 2 parts of aluminum nitride, 1 part of mullite, 0.4 part of hydroxyethyl methacrylate, 0.1 part of zinc acetate, 2 parts of rubber powder, 3 parts of styrene, 2 parts of resorcinol, 0.1 part of sodium lauryl sulfate, 5 parts of plasticizer, 4 parts of triethanolamine, 6 parts of nano silicon dioxide, polystyrene Carboxylate superplasticizer 2 parts.

[0032] The finely ground slag powder is ground from smelting industry waste slag, specifically a mixture of granulated blast furnace slag and steel slag.

[0033] The pl...

Embodiment 2

[0035] A kind of concrete with high abrasion resistance for hydropower projects, comprising the following raw materials in parts by weight: 35 parts of yellow sand, 3.5 parts of ground slag powder, 18 parts of fly ash, 6 parts of silica micropowder, 35 parts of cement, and 11 parts of potassium feldspar powder , 11 parts of medium sand, 2.5 parts of kaolin, 3.5 parts of anhydrite, 3.5 parts of polyethylene fiber, 3.5 parts of high-strength imitation steel wire fiber, 2.5 parts of aluminum nitride, 1.5 parts of mullite, 0.45 parts of hydroxyethyl methacrylate, acetic acid 0.15 parts of zinc, 2.5 parts of rubber powder, 3.5 parts of styrene, 2.5 parts of resorcinol, 0.15 parts of sodium lauryl sulfate, 6 parts of plasticizer, 4.5 parts of triethanolamine, 6.5 parts of nano calcium carbonate, naphthalene 2.5 parts of aqua.

[0036] The finely ground slag powder is ground from smelting industry waste slag, specifically granulated electric furnace phosphorus slag.

[0037] The pla...

Embodiment 3

[0039] A kind of concrete with high abrasion resistance for hydropower projects, comprising the following raw materials in parts by weight: 40 parts of yellow sand, 4 parts of finely ground slag powder, 20 parts of fly ash, 8 parts of silica micropowder, 40 parts of cement, and 12 parts of potassium feldspar powder , 12 parts of medium sand, 3 parts of kaolin, 4 parts of anhydrite, 4 parts of mineral fiber, 4 parts of high-strength imitation steel wire fiber, 3 parts of aluminum nitride, 2 parts of mullite, 0.5 part of hydroxyethyl methacrylate, zinc acetate 0.2 parts, 3 parts of rubber powder, 4 parts of styrene, 3 parts of resorcinol, 0.2 parts of sodium lauryl sulfate, 8 parts of plasticizer, 5 parts of triethanolamine, 7 parts of nano-iron oxide, naphthalene-based water reducer 3 doses.

[0040]The finely ground slag powder is ground from smelting industry waste slag, specifically a mixture of granulated blast furnace slag and granulated electric furnace phosphorous slag. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com