Dam concrete surface abrasion-resistant coating and coating method thereof

A concrete surface and anti-abrasion technology, which is applied to the surface coating liquid device, polyamide coating, epoxy resin coating, etc., can solve the problem of large amount of cement, performance degradation, and many unstable factors in anti-abrasion concrete To achieve the effect of protecting the safe operation of the dam, good adaptability and weather resistance, and prolonging the safe service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

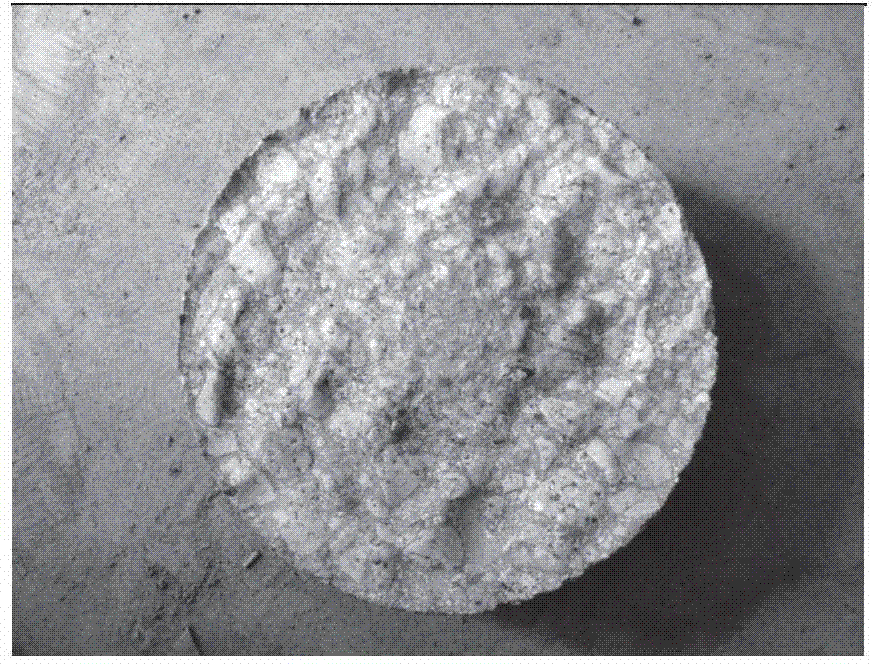

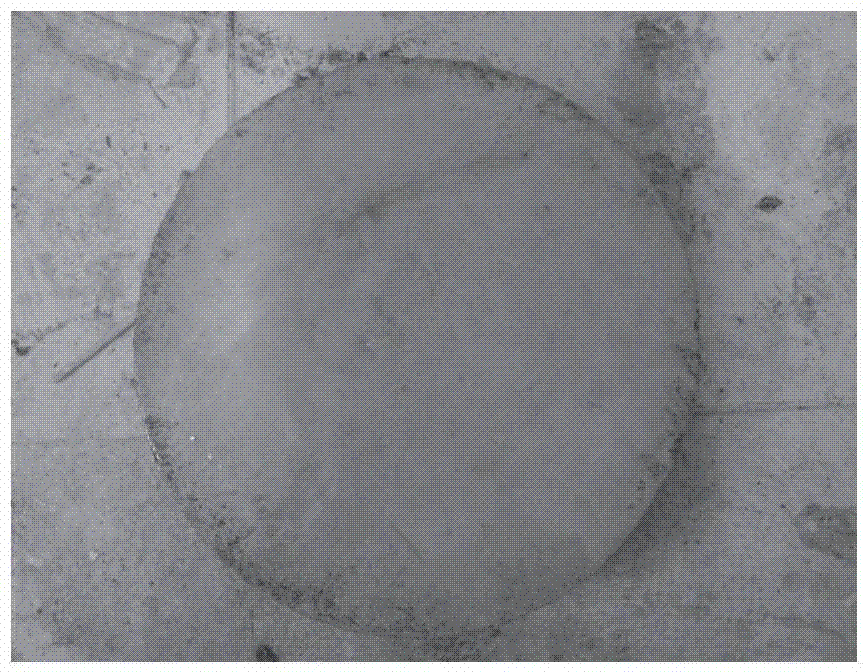

Image

Examples

Embodiment 1

[0025] Preparation of primer:

[0026] The primer coating is epoxy mastic, the initial viscosity of the epoxy mastic is 20000mPa.s, the surface drying time is 5h, and the curing time is 20h.

[0027] Preparation of middle coat:

[0028] The middle coating is a low-viscosity epoxy resin adhesive, and the low-viscosity epoxy resin adhesive is a mixture of A and B two-component materials with a weight ratio of 4:1. Component A is a modified bisphenol A epoxy resin composed of 50 parts by weight of bisphenol A epoxy resin, 25 parts of furfural and 25 parts of acetone. B component is diamine curing agent m-phenylenediamine. The viscosity of the low-viscosity epoxy resin adhesive is 200 mPa.s, the surface dry time is 2 hours, and the curing time is 2 hours.

[0029] Preparation of top coat:

[0030] The surface coating is polyaspartic acid ester polyurea modified by nanometer material, and the polyaspartic acid ester polyurea modified by nanometer material is a mixture of A and ...

Embodiment 2

[0037] Preparation of primer:

[0038] The primer coating is epoxy mastic, the initial viscosity of the epoxy mastic is 50000mPa.s, the surface drying time is 1h, and the curing time is 5h.

[0039] Preparation of middle coat:

[0040] The middle coating is a low-viscosity epoxy resin adhesive, and the low-viscosity epoxy resin adhesive is a two-component material mixture of A and B with a weight ratio of 5:1. Component A is a modified bisphenol A epoxy resin composed of 60 parts by weight of bisphenol A epoxy resin, 20 parts of furfural and 30 parts of acetone. B component is polyamine curing agent triethylamine. The viscosity of the low-viscosity epoxy resin adhesive is 100 mPa.s, the surface dry time is 1.5 h, and the curing time is 1 h.

[0041] Preparation of top coat:

[0042] The surface coating is polyaspartic acid ester polyurea modified by nanometer material, and the polyaspartic acid ester polyurea modified by nanometer material is a mixture of A and B two-compone...

Embodiment 3

[0047] Preparation of primer:

[0048] The primer coating is epoxy mastic, the initial viscosity of the epoxy mastic is 30000mPa.s, the surface drying time is 3h, and the curing time is 15h.

[0049] Preparation of middle coat:

[0050] The middle coating is a low-viscosity epoxy resin adhesive, and the low-viscosity epoxy resin adhesive is a two-component material mixture of A and B with a weight ratio of 6:1. Component A is a modified bisphenol A epoxy resin composed of 55 parts by weight of bisphenol A epoxy resin, 30 parts of furfural and 20 parts of acetone. B component is diamine curing agent hexamethylenediamine. The viscosity of the low-viscosity epoxy resin adhesive is 50 mPa.s, the surface dry time is 1 h, and the curing time is 0.5 h.

[0051] Preparation of top coat:

[0052] The surface coating is polyaspartic acid ester polyurea modified by nanometer material, and the polyaspartic acid ester polyurea modified by nanometer material is a mixture of A and B two-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com