Low-VOC (volatile organic compound) photocuring laser transfer paint and preparation method thereof

A technology of laser transfer and transfer coating, which is applied in the direction of coating, etc., can solve the problems that cannot meet the production requirements, and achieve the effects of wide application range, high molding yield and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

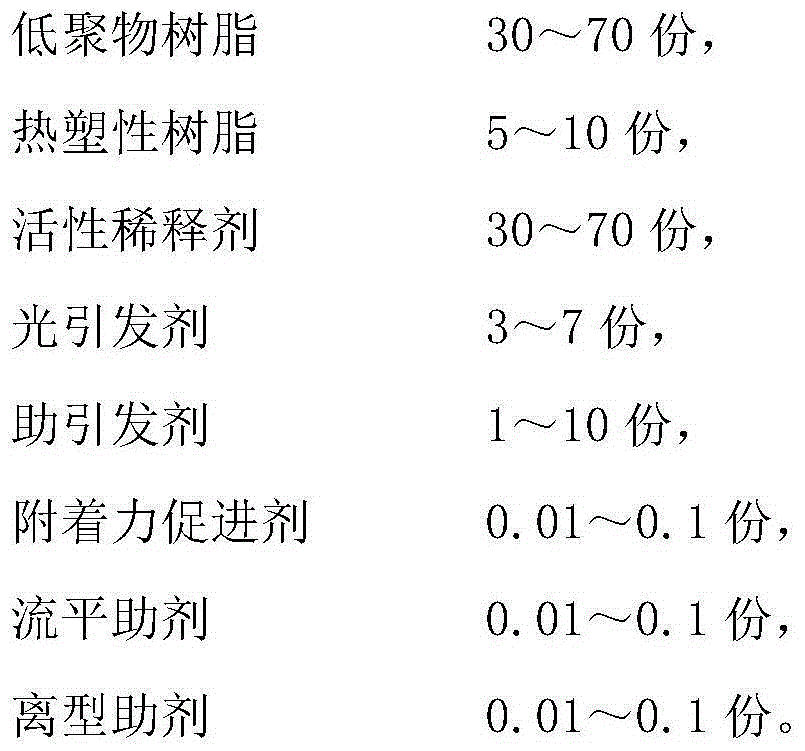

[0031] This embodiment relates to a low-VOC photocurable laser transfer coating for tobacco packaging, which includes the components shown in Table 1 in parts by weight.

[0032] Table 1

[0033]

[0034]

[0035] The preparation method of the transfer coating of the present embodiment comprises the following processing steps:

[0036] (1) Dissolve the above polyurethane acrylate in TMPTA after baking at 60-70°C for 1 hour, and stir until fully dissolved;

[0037] (2) Stir the above-mentioned organosilicon-modified epoxy acrylate and the remaining HDDA active diluent until fully dissolved;

[0038] (3) Stir and mix the mixture obtained in step (2) with the mixture obtained in step (1);

[0039] (4) add above-mentioned initiator and co-initiator in step (3) gained mixture, high-speed stirring mixes;

[0040] (5) Add the above-mentioned polyether-type modified silicone leveling agent, silane coupling agent, and polyether-modified silicone oil to the mixture obtained in ...

Embodiment 2

[0051] This embodiment relates to a low-VOC photocurable laser transfer coating for tobacco packaging, which includes the components shown in Table 3 in parts by weight.

[0052] table 3

[0053]

[0054] The preparation method of the transfer coating of the present embodiment comprises the following processing steps:

[0055] (1) Dissolve the above polyurethane acrylate in HDDA after drying at 60-70°C for 1 hour, and stir until fully dissolved;

[0056] (2) Stir the above-mentioned organosilicon-modified epoxy acrylate and TMPTA reactive diluent until fully dissolved;

[0057](3) Stir and mix the mixture obtained in step (2) with the mixture obtained in step (1);

[0058] (4) add above-mentioned initiator and co-initiator in step (3) gained mixture, high-speed stirring mixes;

[0059] (5) Add the above-mentioned polyether-type modified silicone leveling agent, silane coupling agent, and polyether-modified silicone oil to the mixture obtained in step (4), stir and mix ev...

Embodiment 3

[0062] This embodiment relates to a low-VOC photocurable laser transfer coating for tobacco packaging, which includes the components shown in Table 4 in parts by weight.

[0063] Table 4

[0064]

[0065] The preparation method of the transfer coating of the present embodiment comprises the following processing steps:

[0066] (1) Dissolve the above polyurethane acrylate in 20kg of HDDA and DPGDA mixed solution after drying at 60-70°C for 1 hour, and stir until fully dissolved;

[0067] (2) Stir the mixed solution of the above-mentioned organosilicon-modified epoxy acrylate with the remaining HDDA and DPGDA until fully dissolved;

[0068] (3) Stir and mix the mixture obtained in step (2) with the mixture obtained in step (1);

[0069] (4) add above-mentioned initiator and co-initiator in step (3) gained mixture, high-speed stirring mixes;

[0070] (5) Add the above-mentioned polyether-type modified silicone leveling agent, silane coupling agent, and polyether-modified si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com