Bionic self-healing material for air leakage stoppage in coal mine

A technology of healing material and plugging air, applied in the field of coal mine plugging air material, can solve the problems of inability to achieve permanent sealing, spontaneous combustion of coal seams in mined areas, underground environmental pollution, etc. Strength, the effect of protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

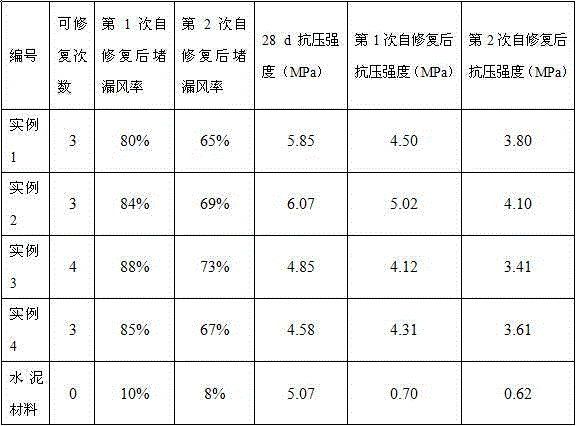

Examples

Embodiment Construction

[0022] The following examples are a further detailed description of the present invention.

[0023] 1. Example:

[0024] (1) Preparation of urea-formaldehyde prepolymer: mix urea and formaldehyde solution (mass fraction of 37%) at a molar ratio of 1:1, adjust the pH to 9-10 with triethanolamine, and heat the temperature to 60°C for 1 hour .

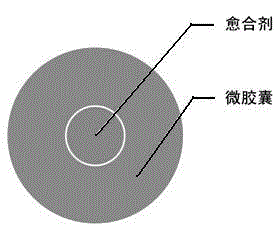

[0025] (2) Preparation of microcapsules: the urea-formaldehyde prepolymer is cooled to room temperature, and the surfactant sodium lauryl aminopropionate 0.5-1% or sodium dodecylbenzene sulfonate 0.5-1%, or Nonylphenol polyoxyethylene 0.5-1%; then add the core material (epoxy resin and n-butyl glycidyl ether mixture, epoxy resin and n-butyl glycidyl) with a mass of 50-60% of the mass of the urea-formaldehyde prepolymer The ratio of ether is 5:1, or phenolic resin); add defoamer n-octanol (accounting for 0.2-1.5% of the mass of urea-formaldehyde prepolymer), emulsify for 25 minutes, adjust the pH to about 2 with dilute sulfuric acid, and heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com