Iron-doped molybdenum disulfide coating material and preparation method and application thereof

A molybdenum disulfide, coating material technology, applied in coatings, antifouling/underwater coatings, metal material coating processes, etc., can solve problems such as hidden dangers, affecting the normal physiological process of tissue cells, and narrow light wavelength range, etc. Achieve the effect of improving the antibacterial effect, avoiding potential safety hazards and application problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] As an example, further describe the preparation method of the iron-doped molybdenum disulfide coating, including: cleaning the titanium or titanium alloy through oxalic acid pickling and placing it in the reactor, using (a) sulfur source, (b ) molybdenum source, (c) iron source, (d) mixed aqueous solution or hydrosol of chelating agent as hydrothermal medium for hydrothermal treatment. Wherein, the reaction temperature is 180-220°C, the reaction time is 4-8 hours, and it is the best to keep the filling degree of the reactor at 50-75% in the whole process; the sulfur source is thiourea, thioacetamide, cysteine , sodium sulfide, potassium sulfide, etc. The source of molybdenum is sodium molybdate dihydrate, ammonium paramolybdate hexahydrate or ammonium thiomolybdate, etc. The source of iron can be soluble salts of iron (II) or iron (III) such as Ferric chloride, ferrous sulfate or ferrous ammonium sulfate, etc. The chelating agent can be ethylenediaminetetraacetic acid, ...

Embodiment 1

[0048] Treat a titanium sheet with a thickness of 1mm and a length and width of 10mm with 10% oxalic acid solution at 80°C for 2 hours, then rinse it with a large amount of deionized water, and then use alcohol and deionized water to clean it ultrasonically, each time for 15 minutes , to obtain titanium (o-Ti) treated with oxalic acid. Then carry out hydrothermal treatment, add 0.6g CS(NH 2 ) 2 , 0.28g (NH 4 ) 6 Mo 7 o 24 ·6H 2 O, 0.28g FeSO 4 ·7H 2 O and 0.37g disodium edetate (C 10 h 14 N 2 Na 2 o 8 2H 2 O), after ultrasonic dissolution, transfer to a 100mL PPL hydrothermal reaction kettle, the hydrothermal temperature is 200°C, and the time is 5h. Rinse and sonicate with a large amount of deionized water after water heating;

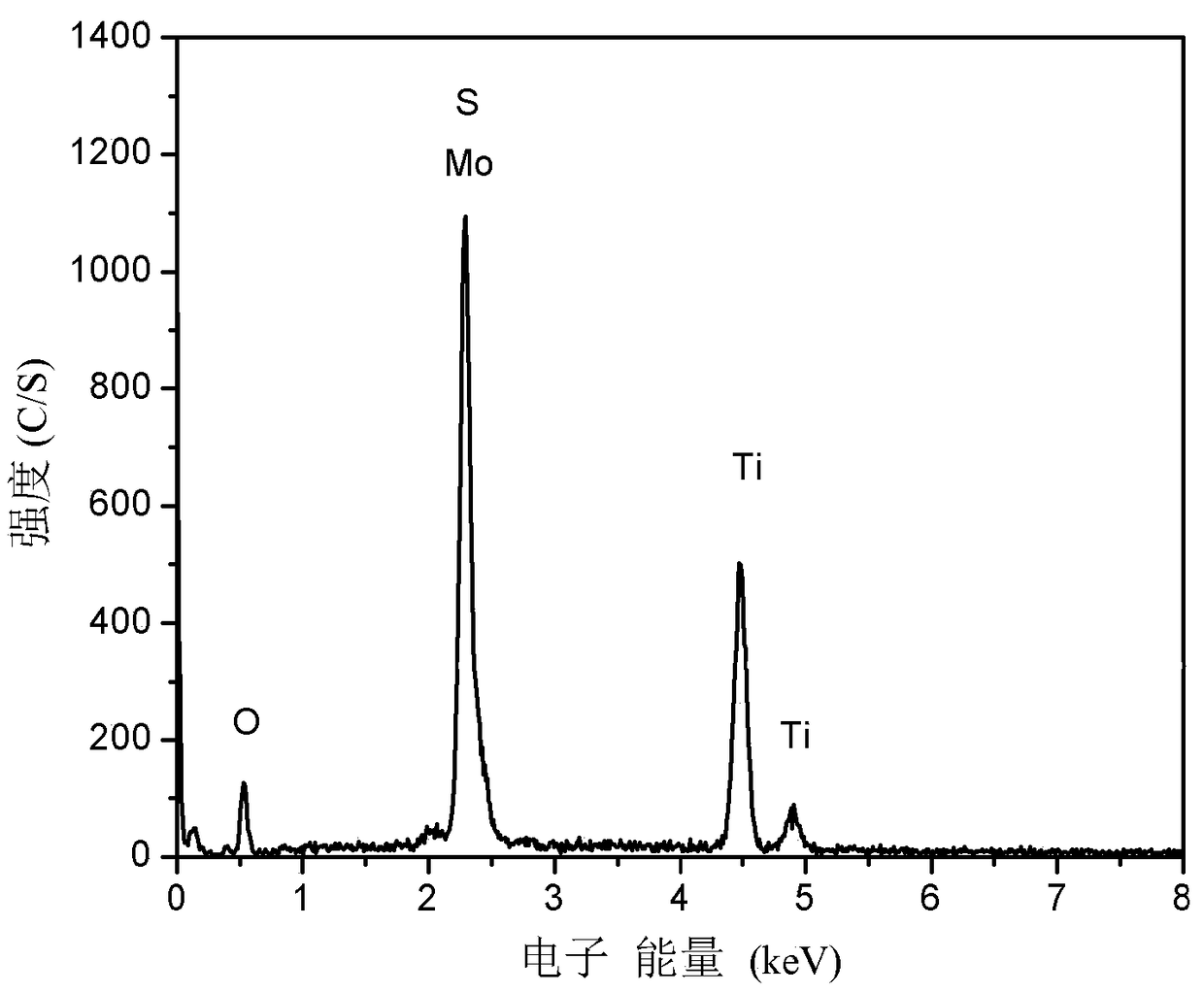

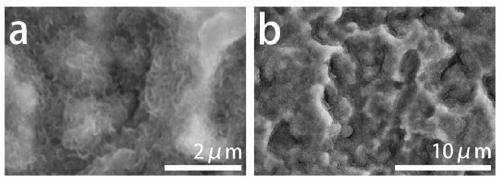

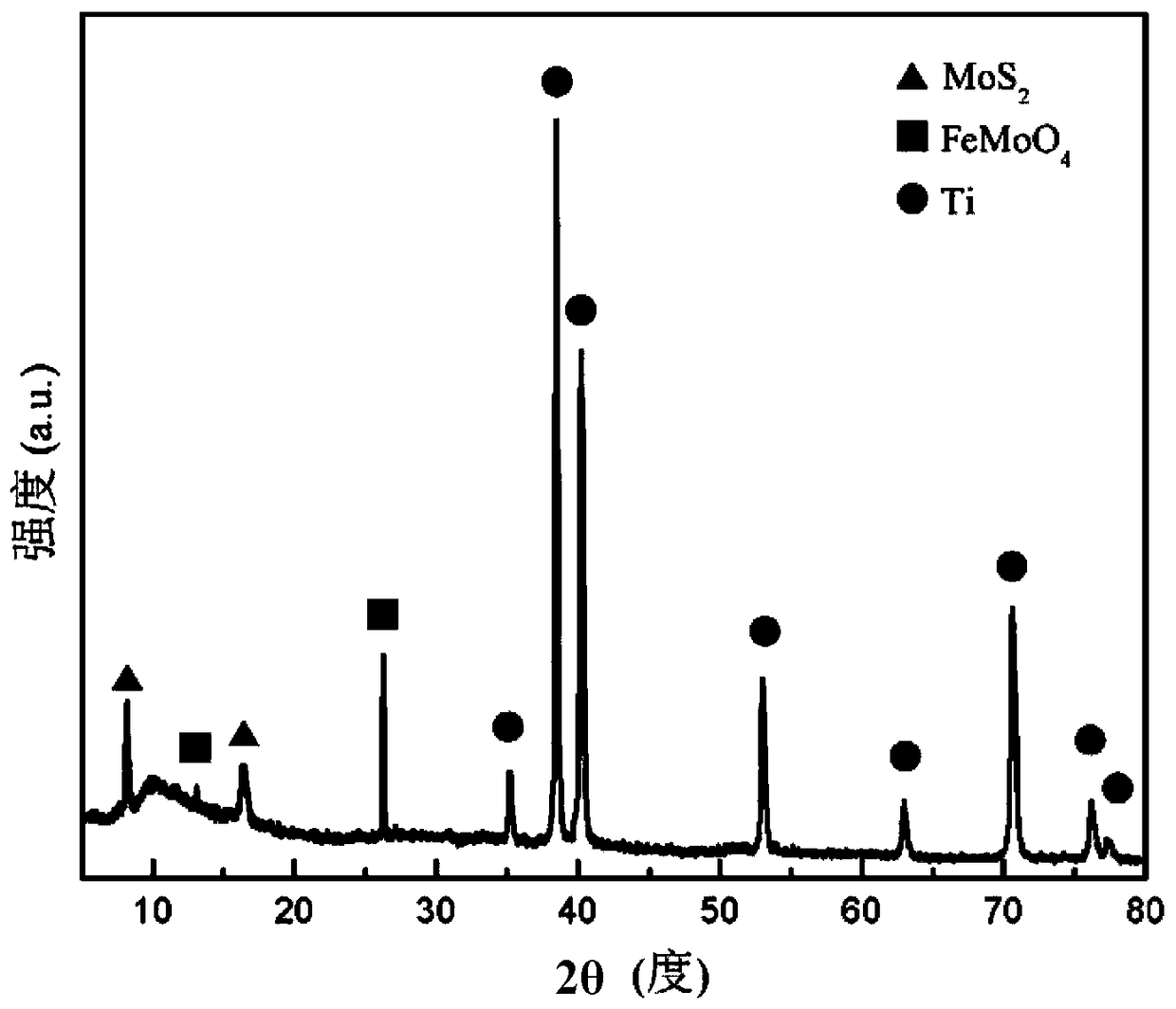

[0049] figure 1 (o-Ti-MoS 2 -Fe) is the low-power (b) and high-power (a) scanning electron microscope pictures of the iron-doped molybdenum disulfide coating material morphology on the surface of the titanium sheet obtained through t...

Embodiment 2

[0051] Antibacterial experiments were carried out on the materials prepared in Example 1, and the titanium alloy treated with oxalic acid in Example 1 was used as a control (marked as o-Ti): all samples were sterilized by a volume fraction of 75% alcohol solution and ultraviolet radiation. After the sample was dried, the bacteria solution with a concentration of 107 CFU / mL was dropped on the surface of the sample in the sterilizer (0.05 mL / cm 2 ), and then put the sample dripped with the bacterial solution into a 37°C constant temperature incubator for 24h. The samples cultivated for 24 hours were taken out, fixed with 2.5% glutaraldehyde solution by volume fraction, dehydrated and dried by gradient alcohol solution and hexamethyldisilazane solution, and observed under scanning electron microscope.

[0052] Figure 5 For the antibacterial results of Escherichia coli and Staphylococcus aureus by the iron-doped molybdenum disulfide coating obtained after the above-mentioned emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com