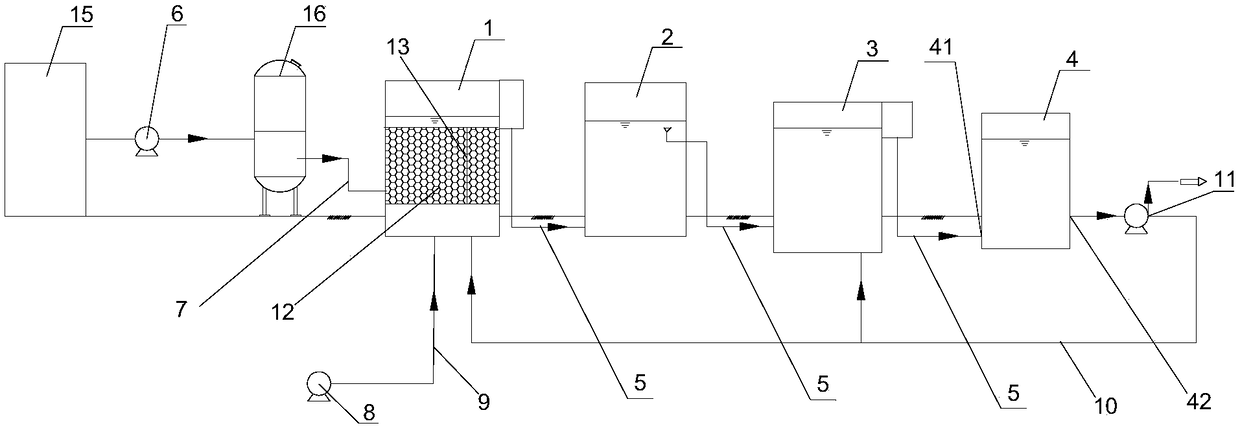

Circulating water pollution emission standard-reaching treatment device

A treatment device and circulating water technology, applied in water/sewage treatment, biological water/sewage treatment, oxidized water/sewage treatment, etc., can solve high operating costs, failure to meet discharge requirements, and unsatisfactory treatment effects of advanced sewage treatment processes etc. to achieve low operating costs, improve biodegradability, and ensure microbial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

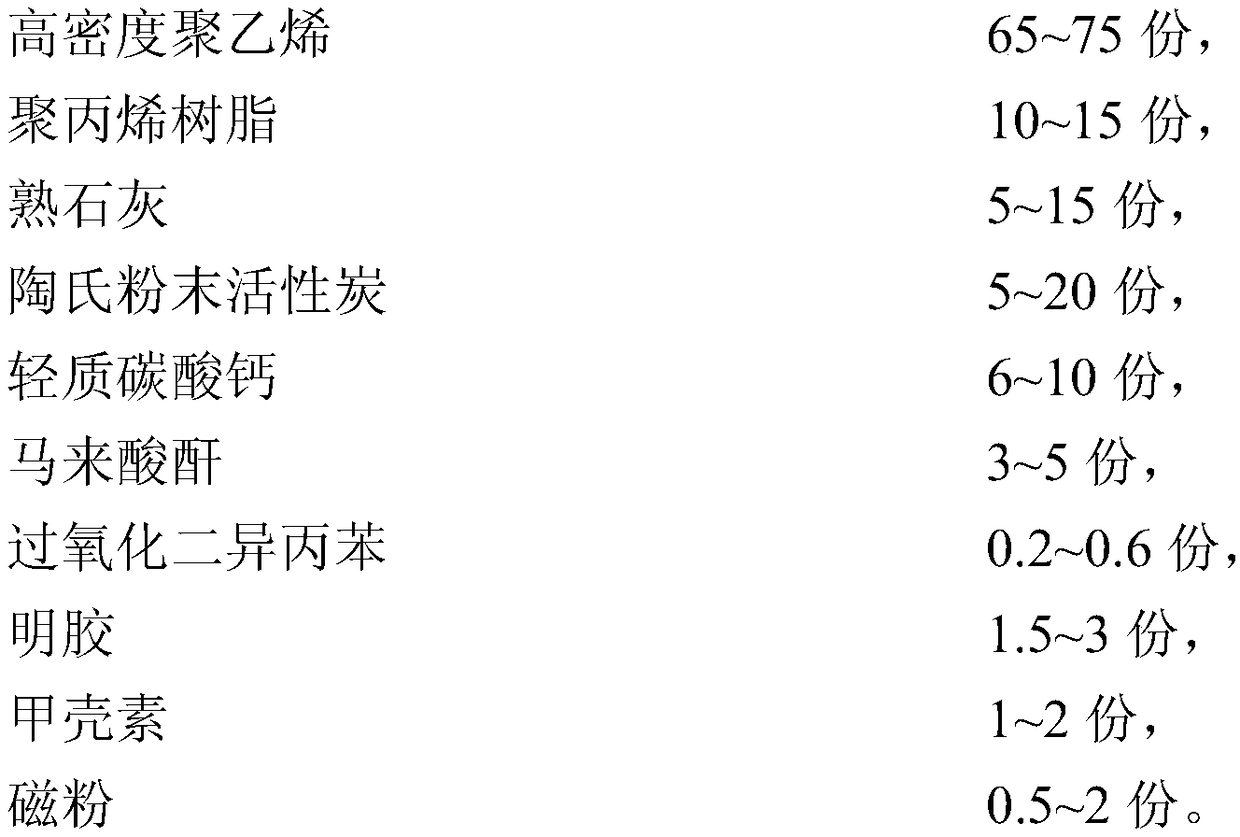

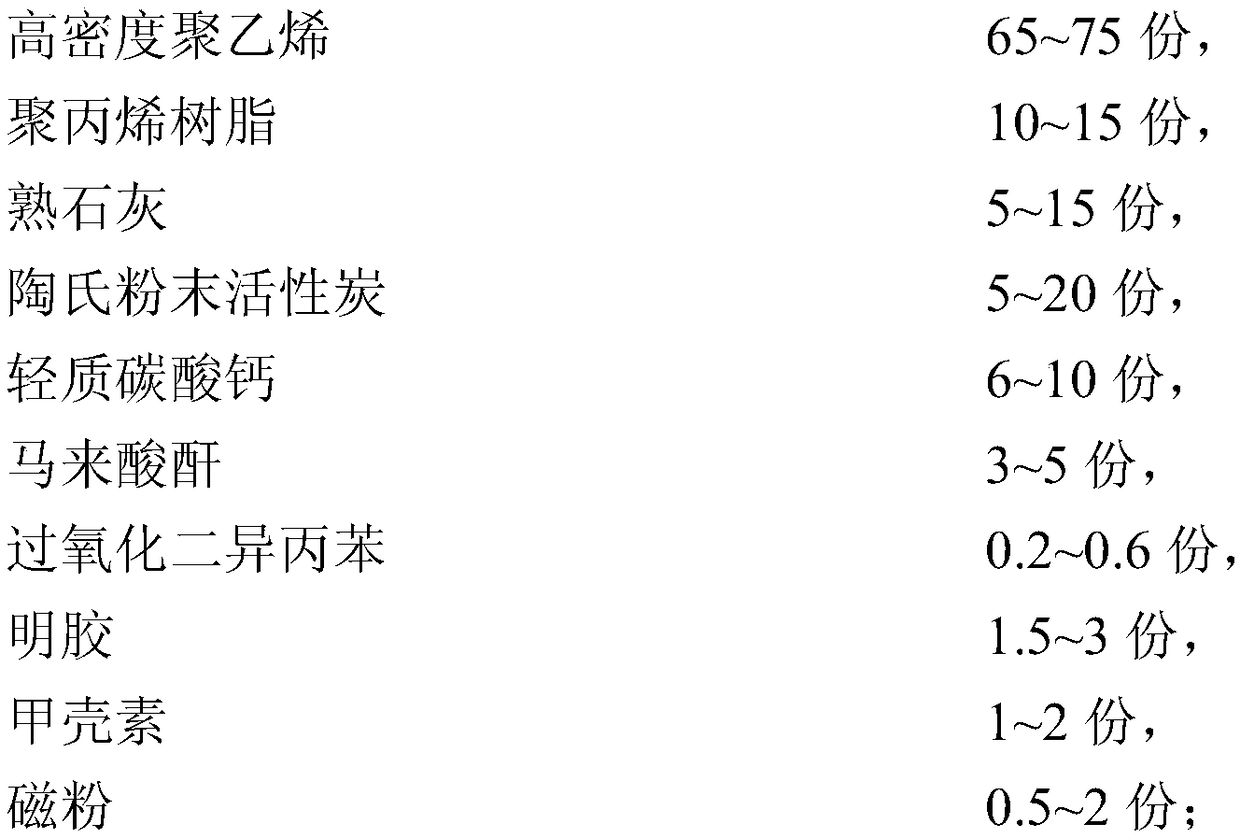

[0034] Several biological fillers are placed in the post-biochemical BAF pool 3, and the biological fillers are composed of a carrier and a microbial film hanging on the surface of the carrier;

[0035] The preparation method for placing several biological filler carriers in the post-biochemical BAF pool 3 comprises the following steps:

[0036] Weigh 72 parts of high-density polyethylene, 12 parts of polypropylene resin, 8 parts of hydrated lime, 18 parts of Dow powdered activated carbon, 8 parts of light calcium carbonate, 4 parts of maleic anhydride, 0.25 parts of dicumyl peroxide, and 1.8 parts of gelatin parts, 1.8 parts of chitin, and 0.8 parts of magnetic powder ferromagnetic powder.

[0037] Step 1, get 4 parts of maleic anhydride, 0.25 part of dicumyl peroxide, dissolve them with 2.5 kilograms of acetone to make acetone solution, place in mixer;

[0038] Step 2: Add 72 parts of high-density polyethylene, 12 parts of polypropylene resin, 8 parts of slaked lime, 18 par...

Embodiment 2-4

[0046] The contents of the biological filler carriers placed in the post-biochemical BAF pool 3 of Examples 2-4 are shown in Table 1, and the rest are the same as in Example 1.

[0047] The prepared biological filler carrier was subjected to BAF biochemical test, and the test results are shown in Table 2.

[0048] The test result of table 2 carrier

[0049]

[0050] It can be seen from Table 2 that the film-hanging time of the carrier prepared by the method of the present invention is obviously shortened, and the removal rate of COD and ammonia nitrogen is obviously improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com