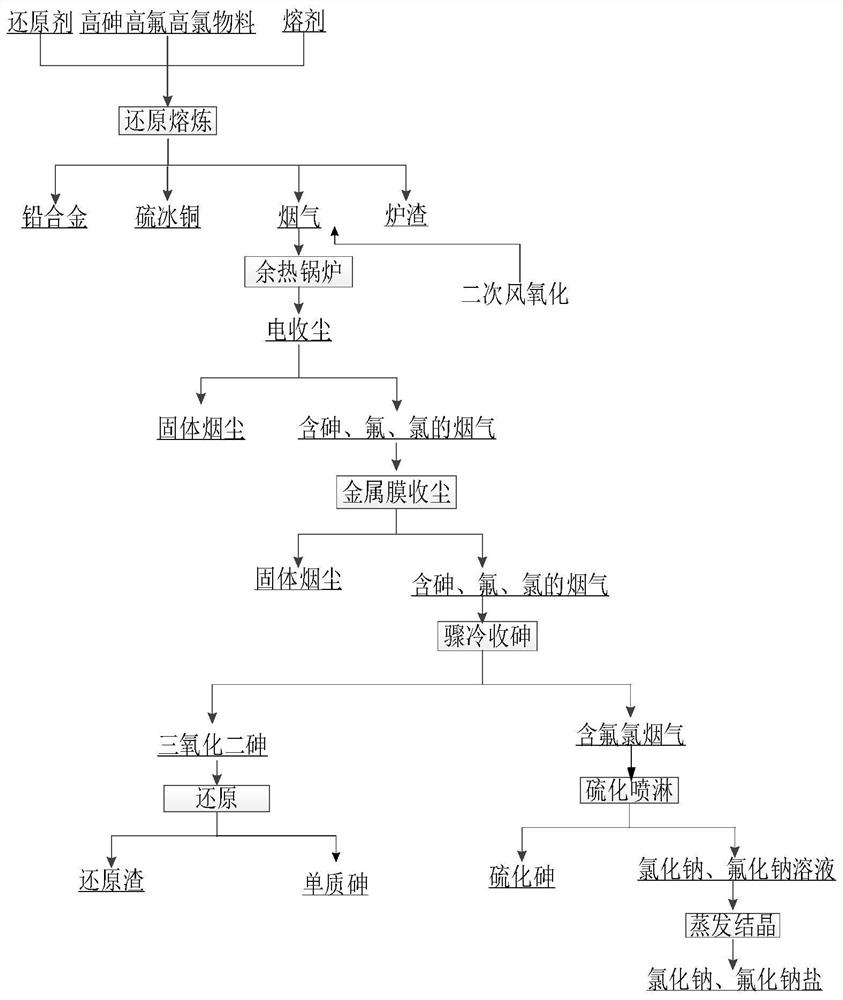

A cleaning method for high-arsenic, fluorine- and chlorine-containing materials

A technology for cleaning treatment and materials, applied in the directions of arsenic compounds, alkali metal fluorides, alkali metal chlorides, etc., it can solve the problems of air pollution, secondary pollution, ignoring arsenic and fluorine and chlorine harmful substances, etc., to ensure clean emissions , the effect of efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

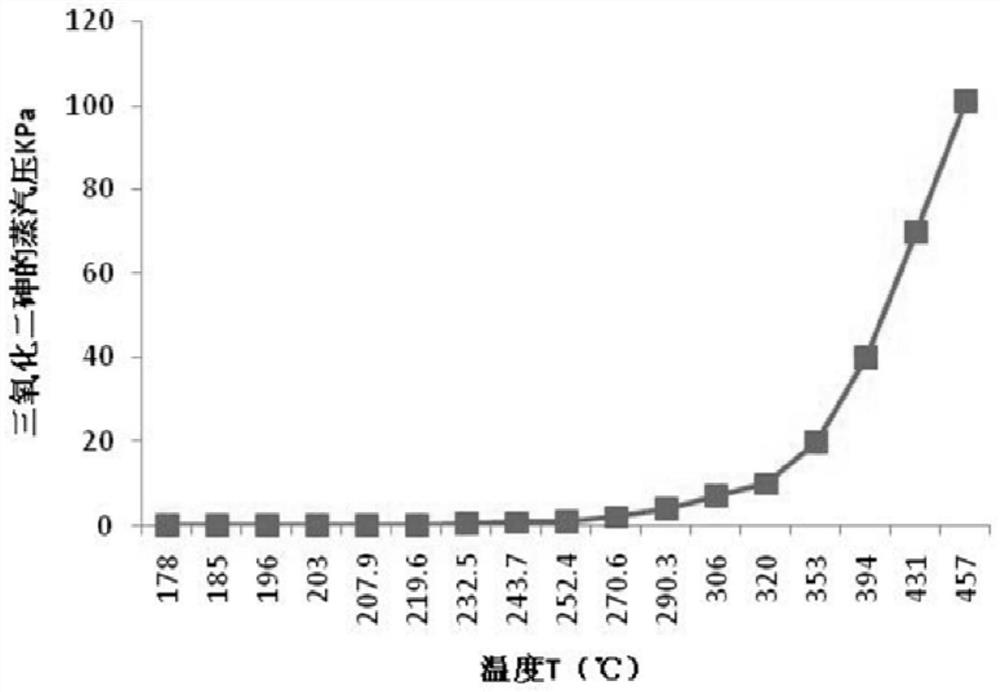

[0091] Coal, iron filings, quartz stone, and limestone are mixed according to 10.34%, 6.91%, 4.11%, and 1.66% of the mass (25t) of high-arsenic, fluorine- and chlorine-containing materials, respectively, and added to the oxygen-enriched side-blown furnace. The oxygen-enriched side-blown reduction furnace Oxygen-enriched air (purity 50%, oxygen-coal ratio 650Nm 3 / t), the reduction smelting was carried out at a temperature of 1200°C for 90 minutes. During the smelting process, the lead was relatively heavy and sank to the bottom of the side-blowing furnace, and the upper layer of the melt was slag. Lead alloy (matte Cu35.26%, Pb5.27%, Fe2.45%, S5.78%; lead-bismuth alloy Pb92.21%, Bi1.34%, Sn0.56%, Ag0.05%, Sb0. 57%) is released from the lead outlet of the side-blowing furnace. The temperature of the smelting flue gas at the outlet of the oxygen-enriched side-blowing furnace is 1150°C (the main component is: As 2 o 3 , As 2 S 3 , CO, CO 2 , SO 2 , HCl, HF, AsCl 3 , AsF ...

Embodiment 2

[0095] Coal, iron filings, quartz stone, and limestone are mixed according to 13.12%, 7.41%, 4.65%, and 2.01% of the mass (25t) of high-arsenic, fluorine-containing and chlorine-containing materials, respectively, and added to the oxygen-enriched side-blown furnace, and the oxygen-enriched side-blown reduction furnace Oxygen is blown into the medium (purity 50%, oxygen-coal ratio is 650Nm 3 / t), the reduction smelting was carried out at a temperature of 1250°C for 120 minutes. During the smelting process, the lead was relatively heavy and sank to the bottom of the side-blowing furnace, and the upper layer of the melt was slag. Lead alloy (matte Cu37.23%, Pb7.83%, Fe3.45%, S2.45%; lead-bismuth alloy Pb89.45%, Bi2.34%, Sn0.63%, Ag0.04%, Sb0. 65%) is released from the lead outlet of the side blowing furnace. The temperature of the smelting flue gas at the outlet of the oxygen-enriched side-blowing furnace is 1150°C (the main component is: As 2 o 3 , As 2 S 3 , CO, CO 2 , SO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com