A comprehensive recovery method for high-arsenic and multi-metal indium-containing materials

A recycling method and multi-metal technology, applied in the direction of improving process efficiency, etc., can solve the problems of difficulty in capturing arsenic-containing smoke, increasing the pressure of electric dust collection, and increasing the processing capacity of subsequent processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

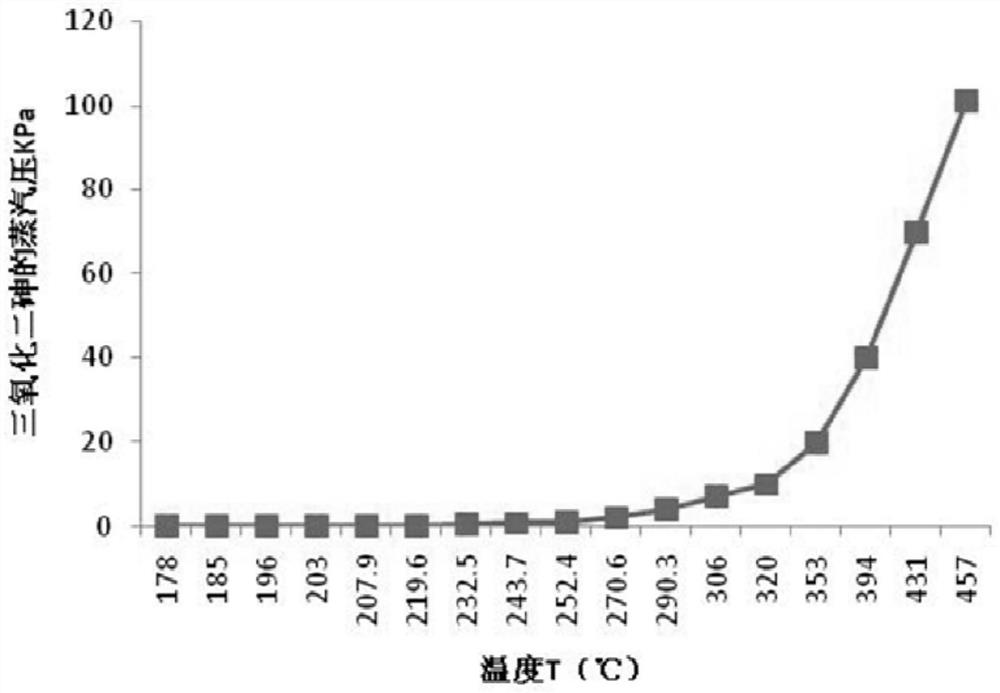

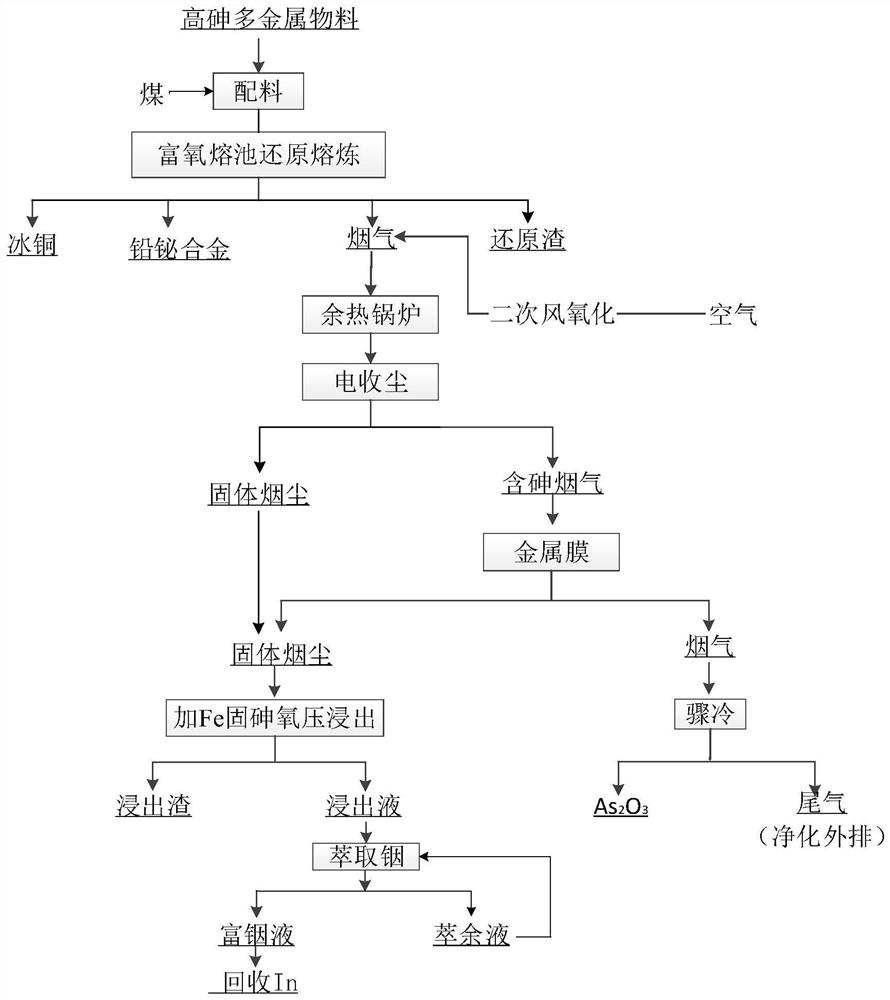

[0084] Coal, iron filings, quartz stone, and limestone are mixed according to 10.34%, 6.91%, 4.11%, and 1.66% of the mass of the high-arsenic polymetallic indium-containing material (25t), respectively, and added to the oxygen-enriched side-blowing furnace, and the oxygen-enriched side-blown reduction Oxygen-enriched air (purity 50%, oxygen-coal ratio 650Nm) is blown into the furnace 3 / t), at a temperature of 1200°C, reduction smelting was carried out for 90 minutes. During the smelting process, the lead was relatively large and sank into the side-blowing furnace. The upper layer of the melt was slag, and the lead alloy (matte copper Cu35. %, Fe2.45%, S5.78%; lead-bismuth alloy Pb92.21%, Bi1.34%, Sn0.56%, Ag0.05%, Sb0.57%) are released from the lead outlet of the side blowing furnace. The dust temperature is 1150°C (the main component is: As 2 o 3 , As 2 S 3 , CO, CO 2 , SO 2 , In 2 O, In 2 o 3 ), blast air into the dust (956Nm 3 ) oxidation, and after testing to me...

Embodiment 2

[0088] Coal, iron filings, quartz stone, and limestone are mixed according to 13.12%, 7.41%, 4.65%, and 2.01% of the mass of the high-arsenic polymetallic indium-containing material (25t), respectively, and added to the oxygen-enriched side-blowing furnace, and the oxygen-enriched side-blown reduction Oxygen-enriched air (purity 50%, oxygen-coal ratio 650Nm) is blown into the furnace 3 / t), at a temperature of 1250°C, carry out reduction smelting for 120 minutes. During the smelting process, the lead is relatively heavy and sinks into the side-blowing furnace. The upper layer of the melt is slag, and the lead alloy (matte Cu37.23%, Pb7.83 %, Fe3.45%, S2.45%; lead-bismuth alloy Pb89.45%, Bi2.34%, Sn0.63%, Ag0.04%, Sb0.65%) are released from the lead outlet of the side blowing furnace. The dust temperature is 1150°C (the main component is: As 2 o 3 , As 2 S 3 , CO, CO 2 , SO 2 , In 2 O, In 2 o 3 ), blast air into the flue gas (956Nm 3 ) oxidation, and after testing to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com