A zirconium diboride-zirconia based high temperature solar energy absorbing coating and its preparation method

A solar energy absorption, zirconium diboride technology, applied in coating, metal material coating process, vacuum evaporation coating and other directions, can solve the problems of optical performance attenuation of absorption coating, long production cycle, low deposition rate, etc. The effect of good thermal stability, convenient operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

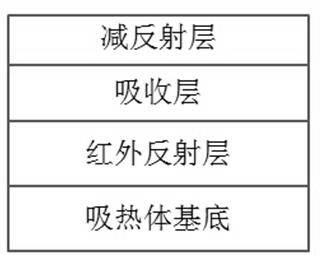

[0021] A method for preparing a zirconium diboride-zirconia-based high-temperature solar energy absorbing coating is carried out according to the following steps:

[0022] (1) Preparation of the infrared reflective layer: use a stainless steel sheet with a surface roughness of 3 nanometers as the substrate, use metal molybdenum Mo with a purity of 99.99% as the target, and use DC magnetron sputtering to pre-pump the vacuum chamber to a background vacuum to 1.0×10 -6 Torr; adjust the sputtering power density of the molybdenum target to 1 W / cm -2 , the intake of argon gas during sputtering deposition was 20 sccm, began to deposit metal molybdenum Mo film on the stainless steel of the endothermic body, the thickness of the metal molybdenum Mo film was 300 nm; during the sputtering process, the temperature of the base stainless steel was 100 o C;

[0023] (2) Preparation of the absorbing layer: After the infrared reflective layer is prepared, zirconium diboride with a purity of ...

Embodiment 2

[0028] A method for preparing a zirconium diboride-zirconia-based high-temperature solar energy absorbing coating is carried out according to the following steps:

[0029] (1) Preparation of the infrared reflective layer: use a stainless steel sheet with a surface roughness of 8 nanometers as the substrate, use metal molybdenum with a purity of 99.99% as the target, and use DC magnetron sputtering to pre-evacuate the vacuum chamber to 7.0×10 -6 Torr; adjust the sputtering power density of the molybdenum target to 5 W / cm -2 , the intake of argon gas during sputtering deposition was 80 sccm, and a molybdenum film was deposited on the stainless steel of the endothermic body with a thickness of 600 nm; during the sputtering process, the temperature of the base stainless steel was 250 o c.

[0030] (2) Preparation of the absorbing layer: After the infrared reflective layer is prepared, zirconium diboride with a purity of 99.99% is used as the magnetron sputtering target. Bottom...

Embodiment 3

[0035] A method for preparing a zirconium diboride-zirconia-based high-temperature solar energy absorbing coating is carried out according to the following steps:

[0036] (1) Preparation of the infrared reflective layer: use a nickel-based alloy with a surface roughness of 5 nanometers as the substrate, use metal molybdenum with a purity of 99.99% as the target, and use DC magnetron sputtering to pre-evacuate the vacuum chamber to 3.5×10 -6 Torr; adjust the sputtering power density of the molybdenum target to 2.5 W / cm -2 , the intake volume of argon during sputtering deposition is 30 sccm, begin to deposit metal molybdenum Mo thin film on the nickel-based alloy of absorber substrate, the thickness of metallic molybdenum Mo thin film is 480 nm; During the sputtering process, the base nickel-based alloy temperature for 200 o c.

[0037] (2) Preparation of the absorbing layer: After the infrared reflective layer is prepared, zirconium diboride with a purity of 99.99% is used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com