Organic glass sheet material with excellent mechanical properties

A technology of plexiglass and performance, applied in the field of organic materials, can solve the problems of not very good mechanical properties and the inability of plexiglass plates to withstand the test of the working environment, etc., to achieve the purpose of expanding practical significance, enhancing mechanical properties, and improving light transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

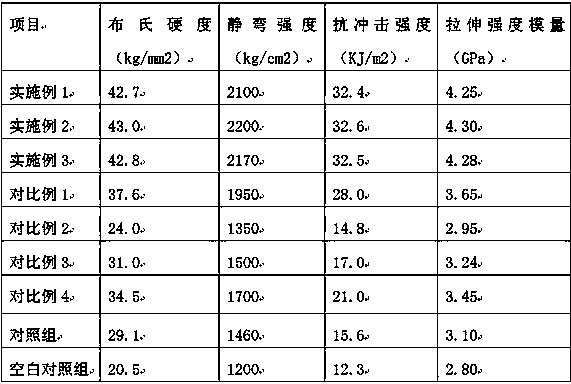

Examples

Embodiment 1

[0017] A plexiglass plate with excellent mechanical properties is made of the following components in parts by weight: 120 parts of methyl methacrylate, 30 parts of allyl methacrylate, 25 parts of butyl acrylate, 7 parts of adipic acid, 1 , 5 parts of 2-propanediol, 1 part of azobisisobutyronitrile, 0.8 parts of sodium lauryl sulfate, 10 parts of methanol, 3 parts of toughened composite material, the preparation method of the toughened composite material comprises the following steps:

[0018] (1) In an ice-water bath at 0°C, add 20 g of methyltrichlorosilane and 30 ml of ethanol to a four-necked flask, stir at 300 rpm for 30 minutes, and continue to add 6 g of diphenyldichlorosilane, Continue stirring for 15 minutes to carry out alcoholysis, add 30 ml of mixed solvent dropwise to the alcoholysis system, raise the temperature to 55°C, and carry out the hydrolysis reaction for 1 hour under stirring;

[0019] (2) After the reaction is over, let it stand for stratification, remov...

Embodiment 2

[0026] A plexiglass plate with excellent mechanical properties is made of the following components in parts by weight: 125 parts of methyl methacrylate, 33 parts of allyl methacrylate, 28 parts of butyl acrylate, 8 parts of adipic acid, 1 , 6 parts of 2-propanediol, 1.5 parts of azobisisobutyronitrile, 0.9 parts of sodium lauryl sulfate, 11 parts of methanol, 3.5 parts of toughened composite material, the preparation method of the toughened composite material comprises the following steps:

[0027] (1) In an ice-water bath at 2°C, add 22 g of methyltrichlorosilane and 33 ml of ethanol to a four-neck flask, stir at 330 rpm for 35 minutes, and continue to add 7 g of diphenyldichlorosilane, Continue stirring for 18 minutes to carry out alcoholysis, add 35 ml of mixed solvent dropwise to the alcoholysis system, raise the temperature to 58°C, and carry out the hydrolysis reaction for 1.5 hours under stirring;

[0028] (2) After the reaction is over, let it stand for stratification,...

Embodiment 3

[0035] A plexiglass plate with excellent mechanical properties is made of the following components in parts by weight: 130 parts of methyl methacrylate, 35 parts of allyl methacrylate, 30 parts of butyl acrylate, 9 parts of adipic acid, 1 , 8 parts of 2-propanediol, 2 parts of azobisisobutyronitrile, 1.0 parts of sodium lauryl sulfate, 12 parts of methanol, 4 parts of toughened composite material, the preparation method of described toughened composite material comprises the following steps:

[0036] (1) In an ice-water bath at 5°C, add 25 grams of methyltrichlorosilane and 35 milliliters of ethanol to a four-necked flask, stir at 350 rpm for 40 minutes, and continue to add 8 grams of diphenyldichlorosilane, Continue stirring for 20 minutes for alcoholysis, add 40 ml of mixed solvent dropwise to the alcoholysis system, raise the temperature to 60°C, and hydrolyze for 2 hours under stirring;

[0037](2) After the reaction is over, let it stand for stratification, remove the wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com