Preparation method and application of a nitrogen and vanadium co-doped titanium dioxide/bismuth tantalate z-type heterojunction photocatalyst

A titanium dioxide and photocatalyst technology, which is applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of affecting photocatalytic efficiency, unfavorable promotion and use, and high production costs, so as to improve the utilization rate, The effect of easy large-scale industrial production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of nitrogen, vanadium co-doped titanium dioxide, the method comprises the following steps:

[0032] 1. Slowly drop 0.25mL tetrabutyl titanate into 10mL isopropanol, stir and mix well to obtain dispersion A;

[0033]2. Disperse 0.5g of ammonium metavanadate in a mixed solution of 70mL of absolute ethanol and 0.15mL of ultrapure water, and ultrasonically disperse for 0.5h to obtain dispersion B;

[0034] 3. Slowly drop the dispersion A into the dispersion B, reflux at 80°C for 5h, the obtained product V-TiO 2 Washed three times with alcohol and dried under vacuum. Subsequently, the ground V-TiO 2 Put it into a porcelain crucible, put it in a tube furnace, and heat it up to 600 ° C for 4 hours in an ammonia atmosphere. After the calcination is completed and the temperature is lowered to room temperature, the nano-block N / V-TiO can be obtained. 2 catalyst of light.

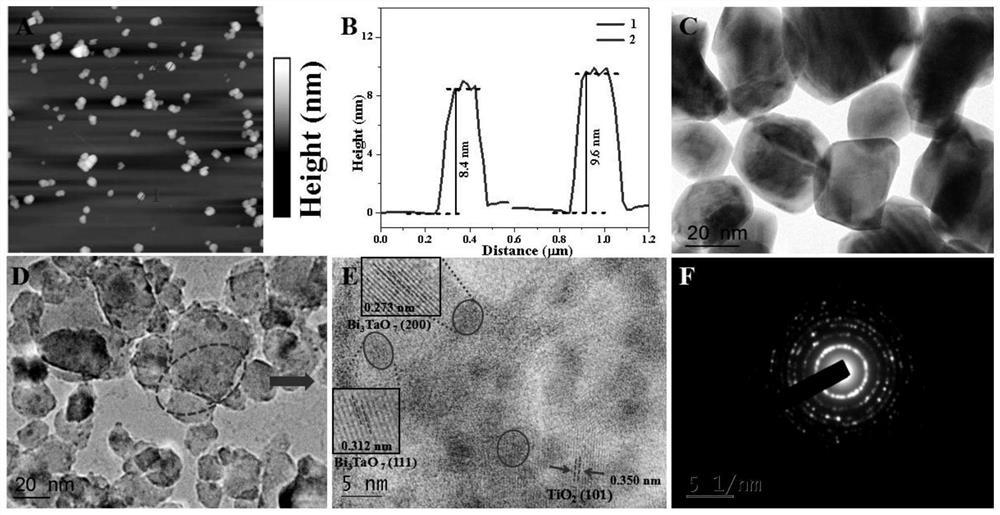

[0035] The N / V-TiO 2 X-ray diffraction patterns of photocatalysts, such as...

Embodiment 2

[0038] A method for preparing nitrogen and vanadium co-doped titanium dioxide / bismuth tantalate Z-type heterojunction photocatalyst, the method comprising the following steps:

[0039] Step 1. Slowly drop 0.1mL tetrabutyl titanate into 5mL isopropanol solution, stir evenly to obtain dispersion A;

[0040] Step 2. Add 0.2g of ammonium metavanadate into 50mL of absolute ethanol, and stir evenly to obtain dispersion B;

[0041] Step 3: Slowly drop the dispersion B into the dispersion A, stir evenly and cool to room temperature naturally after heating and reflux, centrifuge and wash to obtain the product V-TiO 2 , the reflux temperature of the heating reflux treatment is 70°C, and the reflux time is 5h;

[0042] Step 4: Incorporate Step V-TiO 2 Placed in a tube furnace in an ammonia atmosphere, the temperature was raised to 650°C at a heating rate of 3°C / min, kept at a constant temperature for 6h, and then lowered to room temperature at a cooling rate of 5°C / min to obtain nano-b...

Embodiment 3

[0050] A method for preparing nitrogen and vanadium co-doped titanium dioxide / bismuth tantalate Z-type heterojunction photocatalyst, the method comprising the following steps:

[0051] Step 1. Slowly drop 0.3mL tetrabutyl titanate into 20mL isopropanol solution and stir evenly to obtain dispersion A;

[0052] Step 2. Add 0.6g of ammonium metavanadate into 80mL of absolute ethanol and stir evenly to obtain dispersion B;

[0053] Step 3: Slowly drop the dispersion B into the dispersion A, stir evenly and cool to room temperature naturally after heating and reflux, centrifuge and wash to obtain the product V-TiO 2 , the reflux temperature of the heating reflux treatment is 60°C, and the reflux time is 6h;

[0054] Step 4: Incorporate Step V-TiO 2 Placed in a tube furnace in an ammonia atmosphere, the temperature was raised to 800°C at a heating rate of 5°C / min, kept at a constant temperature for 4h, and then lowered to room temperature at a cooling rate of 5°C / min to obtain nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com