A method for preparing samarium cobalt permanent magnet

A permanent magnet, samarium cobalt technology, used in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of inability to take into account the working temperature and comprehensive magnetic performance, low remanence and maximum magnetic energy product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment includes the following steps:

[0047] (1) Ingredients: weigh the raw materials samarium, cobalt, iron, copper, zirconium; mix the raw materials according to the following mass percentages: samarium 26.5%, cobalt 49.2%, iron 14.6%, copper 6.8%, zirconium 2.9%; the prepared The raw materials are smelted in an intermediate frequency induction furnace with a smelting frequency of 40Hz; then the frequency is lowered to 15Hz, kept at 1520°C for 5 minutes, and then poured into a cooling mold for rapid cooling to obtain a samarium-cobalt alloy ingot;

[0048] (2) Coarse crushing of alloy ingots: the samarium-cobalt alloy ingots obtained in step (1) are sequentially crushed by a jaw crusher and a secondary crusher into coarse particles with a particle size of 20-100 microns (μm) to obtain samarium cobalt alloy coarse particles;

[0049] (3) Jet mill powder: the coarse particles are further pulverized to 3-5 μm by jet mill to obtain jet mill magnetic powder;

...

Embodiment 2

[0055] The only difference between this embodiment and embodiment 1 is: in step (5), the sintering temperature is 1230°C. All the other are with embodiment 1.

[0056] The magnetic properties of the samarium cobalt permanent magnet samples prepared in this embodiment were tested, and the test results are shown in Table 1.

Embodiment 3

[0058] The only difference between this embodiment and embodiment 1 is: in step (5), the sintering temperature is 1240°C. All the other are with embodiment 1.

[0059] The magnetic properties of the samarium cobalt permanent magnet samples prepared in this embodiment were tested, and the test results are shown in Table 1.

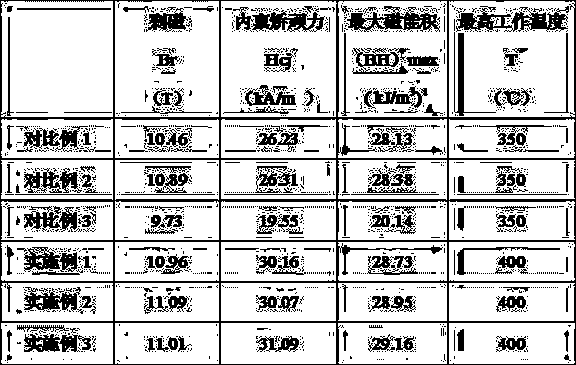

[0060] Table 1

[0061]

[0062] From the comparison of the properties of the samples prepared in the above examples and the comparative examples, it can be seen that the samarium cobalt permanent magnet material prepared in the present invention has both high comprehensive magnetic properties and high working temperature, and can be applied to a high temperature environment of 400°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com