Low-halogen underfill adhesive and preparation method and application thereof

An underfill and halogen technology, used in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of excessive halogen content, environmental and human health threats, environmental hazards of halogen materials, etc., and achieve thermal expansion coefficient. Low, low halogen, low halogen effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

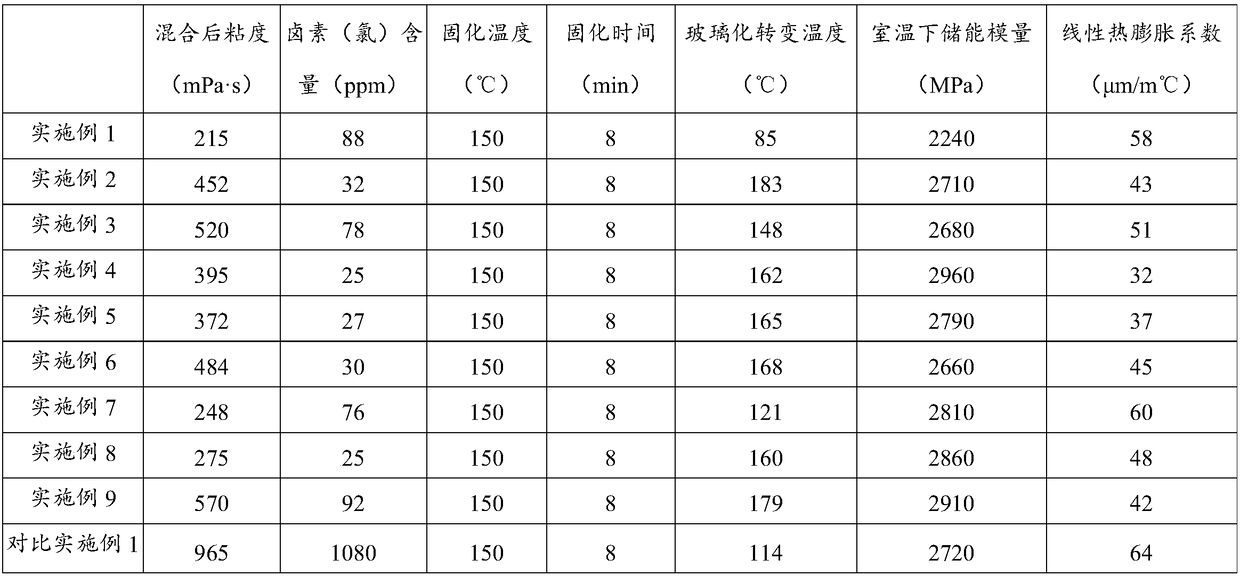

Examples

Embodiment 1

[0045] Accurately weigh 100 parts of electronic grade bisphenol F epoxy resin as EPIKOTE 862 (Shell), 240 parts of nano-silica modified epoxy resin NANOPOX-E601 (Evonik, Germany), trimethylolpropane triacrylate 150 parts, 100 parts of methacrylic acid monomer PLACCEL FM1D (Dacel Japan), 40 parts of 2-ethyl-4 methylimidazole, coupling agent β-(3,4-epoxycyclohexylethyl) trimethoxy 8 parts of silane, 5 parts of defoamer BYK-555 (Germany BYK), 5 parts of high-pigment carbon black, 2 parts of polymerization inhibitor hydroquinone, put them into the planetary agitator, and keep the vacuum at -0.1MPa Mix for 30 minutes, grind the obtained liquid mixture with a three-roller machine, transfer it to a planetary mixer again, add 320 parts of curing agent methyl hexahydrophthalic anhydride, 30 parts of initiator tert-butyl peroxybenzoate, and keep vacuum Mix under the condition of -0.1MPa for 30min to prepare the underfill glue.

Embodiment 2

[0047] Accurately weigh 450 parts of nano-silica modified epoxy resin NANOPOX-E601 (Evonik, Germany), 135 parts of methacrylic acid monomer CYCLOMER M100 (Dacel Japan), 30 parts of 1-cyanoethyl-2-methylimidazole 8 parts, 8 parts of coupling agent γ-(2,3-glycidyloxy) propyltrimethoxysilane, 5 parts of defoamer BYK-A320 (German BYK), 3 parts of high pigment carbon black, polymerization inhibitor Put 2 parts of tert-butylcatechol into the planetary mixer, keep the vacuum and mix at -0.1MPa for 30min, grind the obtained liquid mixture with a three-roll machine, transfer it to the planetary mixer again, add the curing agent methyl tetra 340 parts of hydrophthalic anhydride and 25 parts of tert-butyl peroxy-2-ethylhexanoate as an initiator were mixed for 30 minutes under the condition of -0.1 MPa while maintaining a vacuum to prepare the underfill rubber.

Embodiment 3

[0049] Accurately weigh 70 parts of electronic grade bisphenol A epoxy resin 328 (Shanghai Huayi), 80 parts of alicyclic epoxy resin TTA28 (Jiangsu Taitel), nano-silica modified epoxy resin NANOPOX-E601 ( Germany Evonik) 200 parts, toughening agent EP 5340A (Evonik, Germany) 70 parts, methacrylate laurate 30 parts, methacrylic acid monomer PLACCEL FM1D (Japan Daicel) 70 parts, 1-cyanoethyl-2-ethyl-4-methylimidazole 30 parts, 8 parts of coupling agent β-(3,4-epoxycyclohexylethyl) trimethoxysilane, 5 parts of defoamer BYK-A530 (Bick, Germany), low-halogen black color paste (Polyone, USA) 5 parts, 2 parts of polymerization inhibitor p-benzoquinone, 50 parts of spherical silica powder with a maximum particle diameter of 5 μm, 30 parts of spherical silica powder with a maximum particle diameter of 3 μm, 5 parts of wetting and dispersing agent BYK-W9010 (Germany BYK), put into In the planetary mixer, keep the vacuum and mix for 30min under the condition of -0.1MPa, grind the obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com