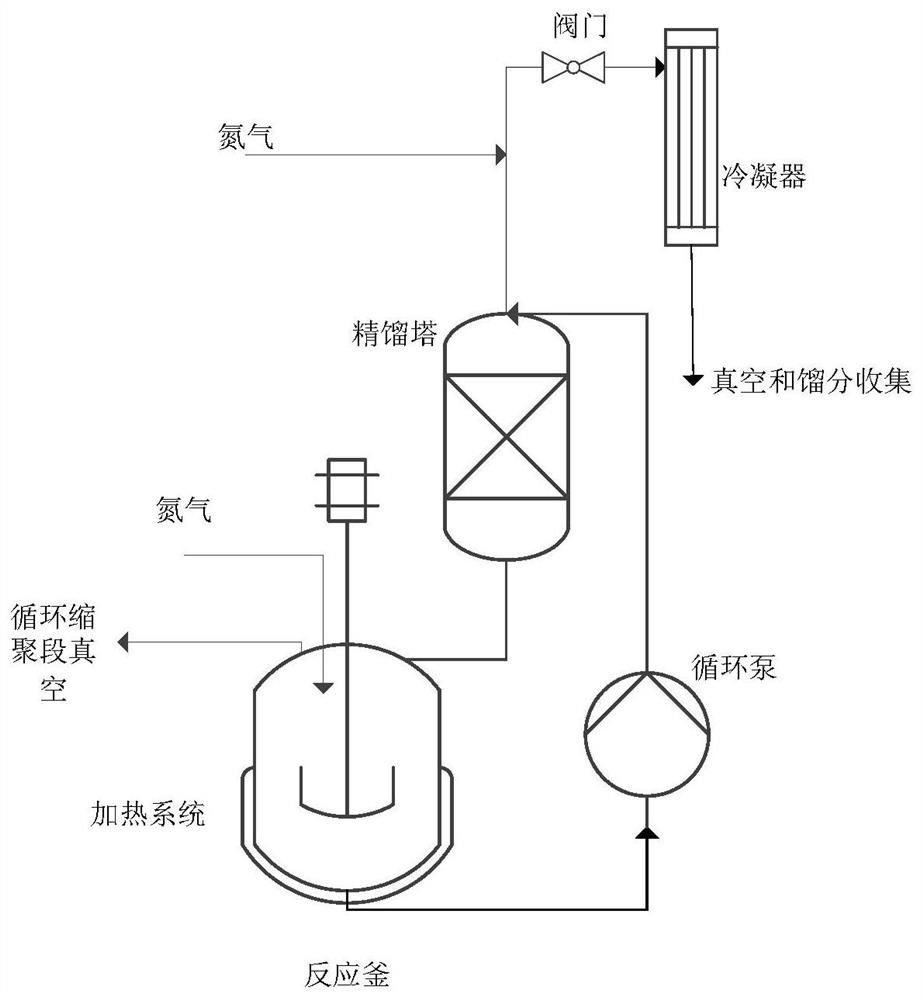

A high-efficiency polycondensation reaction device with an external circulation system and its production process for polyester polyols

A technology for polycondensation reaction and reaction device, applied in the field of polymer material synthesis device and process, can solve the problems of increased equipment and investment, increased system viscosity, unfavorable production efficiency, etc., and achieves reduction of device investment and land occupation, easy removal , the effect of increasing the rate of gasification and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Weigh 285kg of adipic acid and 200kg of 1,4-butanediol and add them to the above-mentioned 500L stainless steel reaction kettle. Evacuate and pass nitrogen three times. Under nitrogen protection, the reaction temperature was 137°C. Start timing since the observation of the rise in the tower top temperature, continuously extract fractions, and control the temperature at the top of the rectifying tower to be 96-98°C. After 2 hours of reaction, the temperature was raised to 180°C at a rate of 45°C / h, and the reaction was continued at 180°C for 2 hours. When the temperature at the top of the tower was observed to drop, use an oil pump to pass through the condenser and evacuate from the upper end of the rectification tower. The system pressure was reduced to 4kPa within the same period, and the temperature was raised to 200°C to continue the reaction for 0.5 hours. The vacuum was turned off and nitrogen was added to equalize the air pressure. The acid value measured by sa...

Embodiment 2

[0064] Weigh 150kg of adipic acid, 114kg of isophthalic acid, 76kg of 1,2-propanediol and 96kg of diethylene glycol into the above-mentioned 500L stainless steel reaction kettle. Evacuate and pass nitrogen three times. Under nitrogen protection, the reaction temperature was 149°C. Start timing since the observation of the rise in the tower top temperature, continuously extract fractions, and control the temperature at the top of the rectifying tower to be 96-98°C. After 2 hours of reaction, the temperature was raised to 230°C at a rate of 60°C / h, and the reaction was continued at 230°C for 2 hours. When the temperature at the top of the tower was observed to drop, an oil pump was used to pass through the condenser and evacuate from the upper end of the rectification tower. The pressure of the system was reduced to 5 kPa, and the reaction was continued at 230° C. for 0.5 hour. The vacuum was turned off and nitrogen was added to equalize the air pressure. Sampling and measuri...

Embodiment 3

[0066] Weigh 250kg of adipic acid, 16.2kg of trimethylolpropane, 36kg of ethylene glycol, and 106kg of diethylene glycol, and add them to the above-mentioned 500L stainless steel reaction kettle. Evacuate and pass nitrogen three times. Under nitrogen protection, the reaction temperature was 130°C. Start counting since the rise of the tower top temperature is observed, and fractions are continuously taken out, and the temperature at the top of the rectifying tower is controlled to be 100-102°C. After reacting for 2 hours, raise the temperature to 210°C at a rate of 110°C / h, and continue to react at 210°C for 2 hours. When the temperature at the top of the tower is observed to drop, use an oil pump to pass through the condenser and evacuate from the upper end of the rectification tower. The system pressure was reduced to 10kPa, nitrogen was bubbled through the nitrogen sparger in the reactor, the nitrogen flow rate was 500L / h, and the reaction was continued for 1 hour. The vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com