Polyester resin and preparation method and application thereof

A polyester resin and polyester technology, applied in the field of polyester resin and its preparation, can solve chemical stability, corrosion resistance, electrical insulation, heat insulation, difficult natural digestion, incomplete alcoholysis reaction, and narrow range of performance changes and other problems, to achieve the effect of excellent mechanical properties and adhesion of the coating, simple preparation method, and better appearance of the board surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Examples are further listed below to describe the present invention in detail. It should also be understood that the following examples are only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention. Some non-essential improvements and adjustments made by those skilled in the art according to the principles set forth in the present invention all belong to the present invention scope of protection. The specific process parameters and the like in the following examples are only examples of the appropriate range, that is, those skilled in the art can make a selection within the appropriate range through the description herein, and are not limited to the specific data exemplified below.

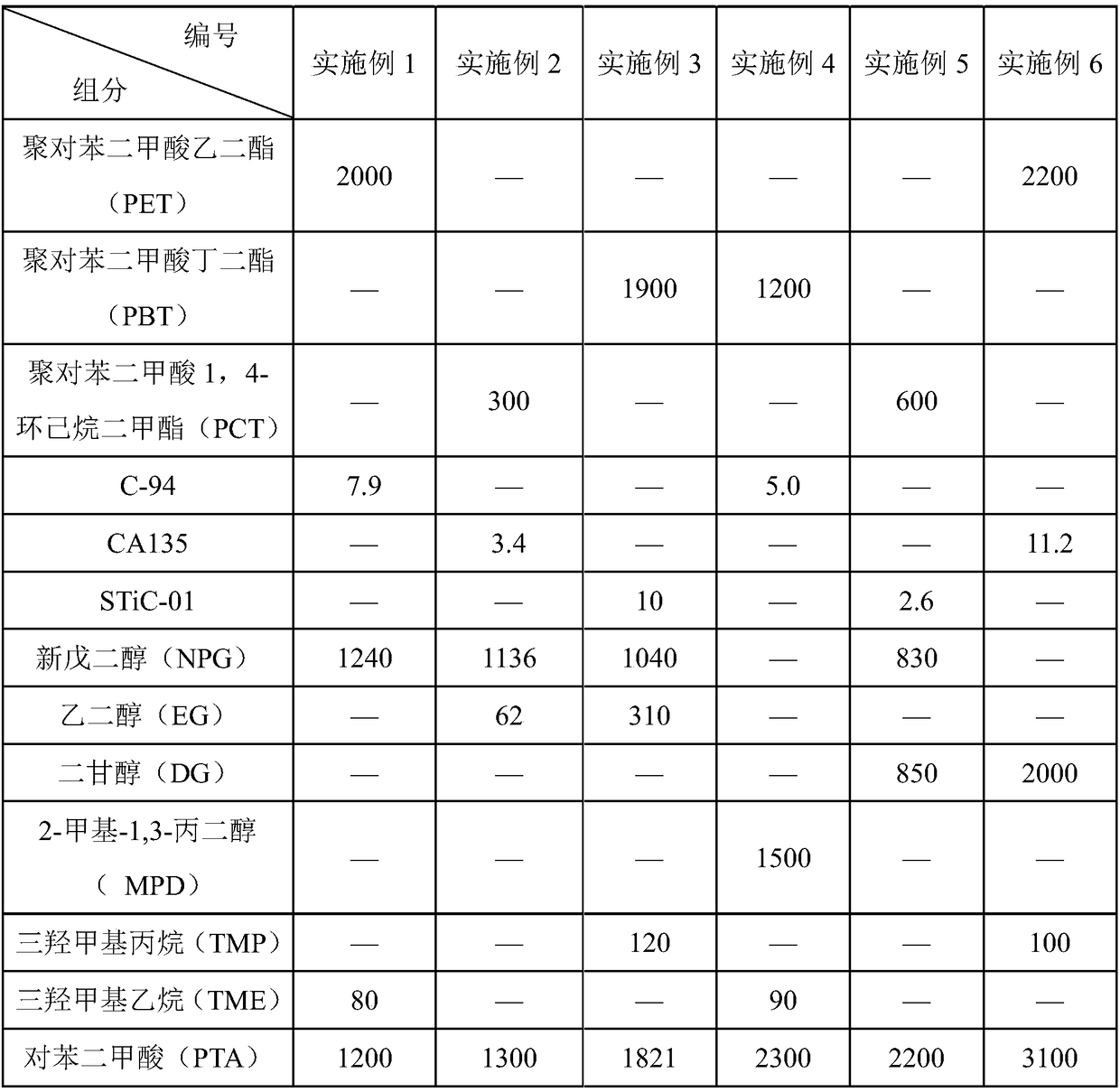

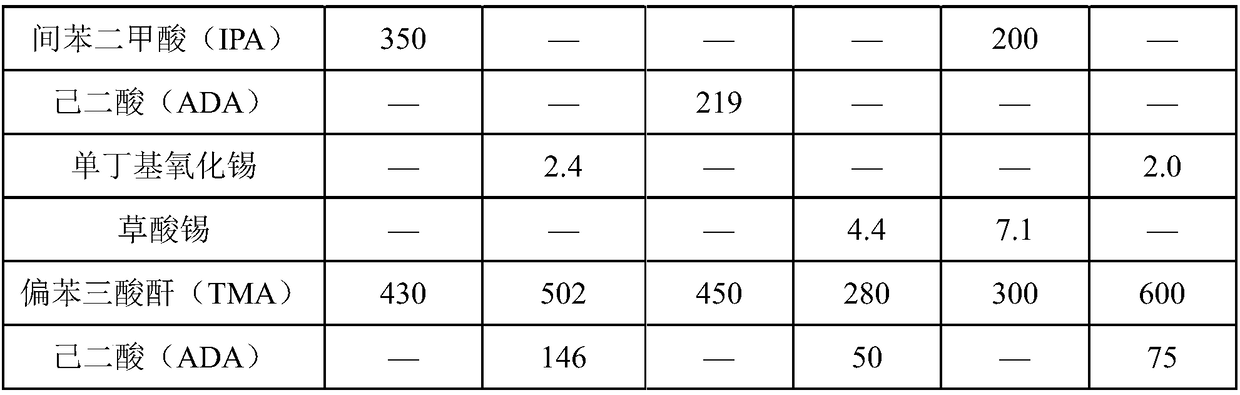

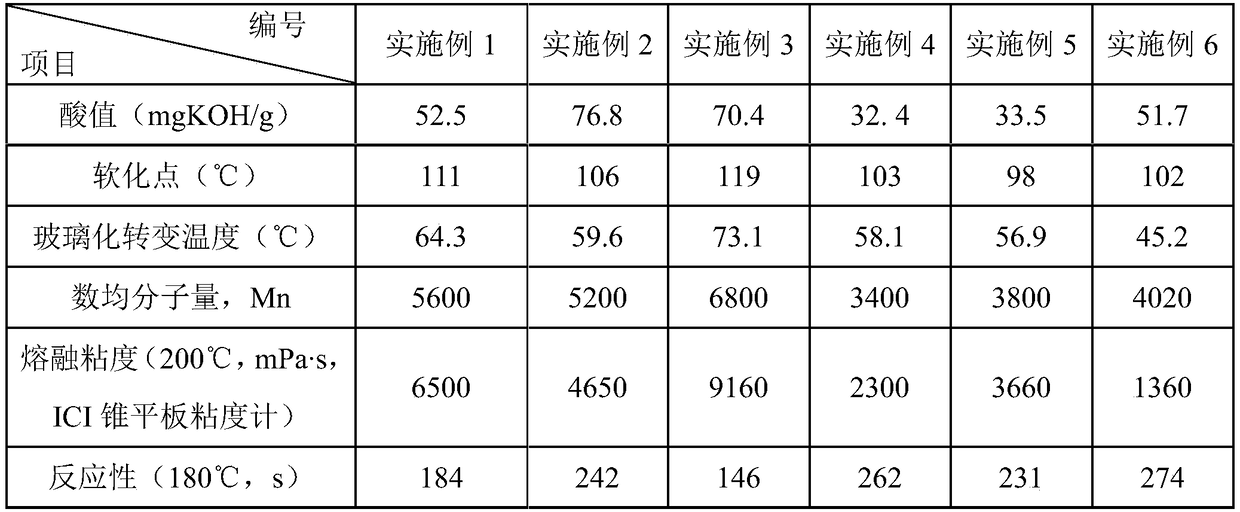

[0039] Below in conjunction with embodiment the present invention is described in detail, and the component of each embodiment polyester resin sees the following table 1 (if no special indication the unit of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com