Preparation method of high-strength superfine dual-phase laminated QAl10-4-4 aluminum bronze alloy plates

An alloy sheet and aluminum bronze technology, which is applied in the field of preparation of high-strength and toughness ultra-fine double-phase layered structure QAl10-4-4 aluminum bronze alloy, can solve the problems of limited material size, lack of wide application, complicated melting process, etc. The effect of excellent comprehensive mechanical properties, ultra-refinement of microstructure, and excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The steps of preparing the high-strength and toughness ultrafine dual-phase lamellar structure QAl10-4-4 aluminum-bronze alloy sheet with the ordinary QAl10-4-4 aluminum-bronze alloy sheet in the hot-rolled state as the initial material are as follows:

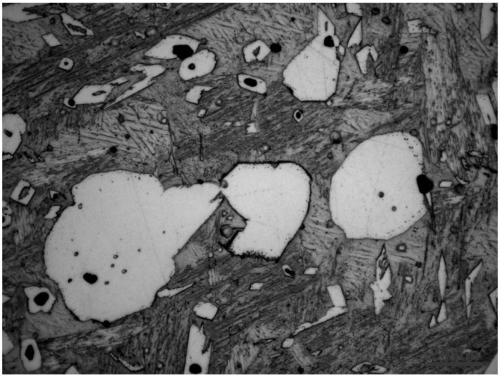

[0030] Step 1, dual-phase microstructure control preheating treatment: place the QAl10-4-4 aluminum bronze alloy sheet with an initial thickness of 10 mm in the hot-rolled state in a heat treatment furnace at 900 ° C for 5 hours to obtain a uniform dual-phase microstructure The first semi-finished plate, the obtained structure is equiaxed α phase, β phase and granular k2 phase, and its typical metallographic structure is shown in the appendix figure 1 ;

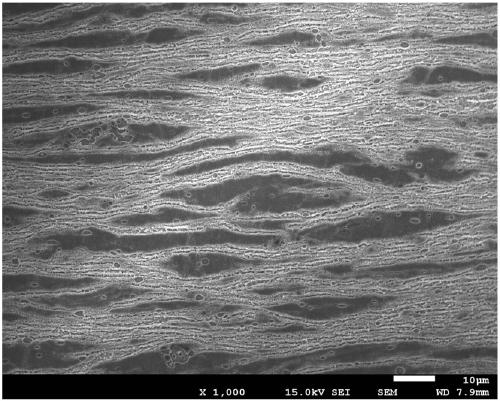

[0031]Step 2, strong deformation asymmetric medium temperature continuous rolling: the first semi-finished plate obtained after the heat treatment of step 1 is immediately subjected to large deformation asymmetric rolling treatment, and the shearing effect generated in...

Embodiment 2

[0035] The steps of preparing the high-strength and toughness ultrafine dual-phase lamellar structure QAl10-4-4 aluminum-bronze alloy sheet with the ordinary QAl10-4-4 aluminum-bronze alloy sheet in the annealed state as the initial material are as follows:

[0036] Step 1, dual-phase microstructure control preheating treatment: place the QAl10-4-4 aluminum bronze alloy sheet with an initial thickness of 10 mm in the hot-rolled state in a heat treatment furnace at 850 ° C for 2 hours to obtain a uniform dual-phase microstructure The first semi-finished panel;

[0037] Step 2, strong deformation asymmetric medium-temperature continuous rolling: the first semi-finished plate obtained after step 1 heat treatment is immediately subjected to large deformation asymmetric rolling treatment, the initial temperature of the roll is room temperature, and the linear speed ratio of the rolls on the upper and lower surfaces of the plate is 1.2 : 1, the asymmetric rolling is divided into two...

Embodiment 3

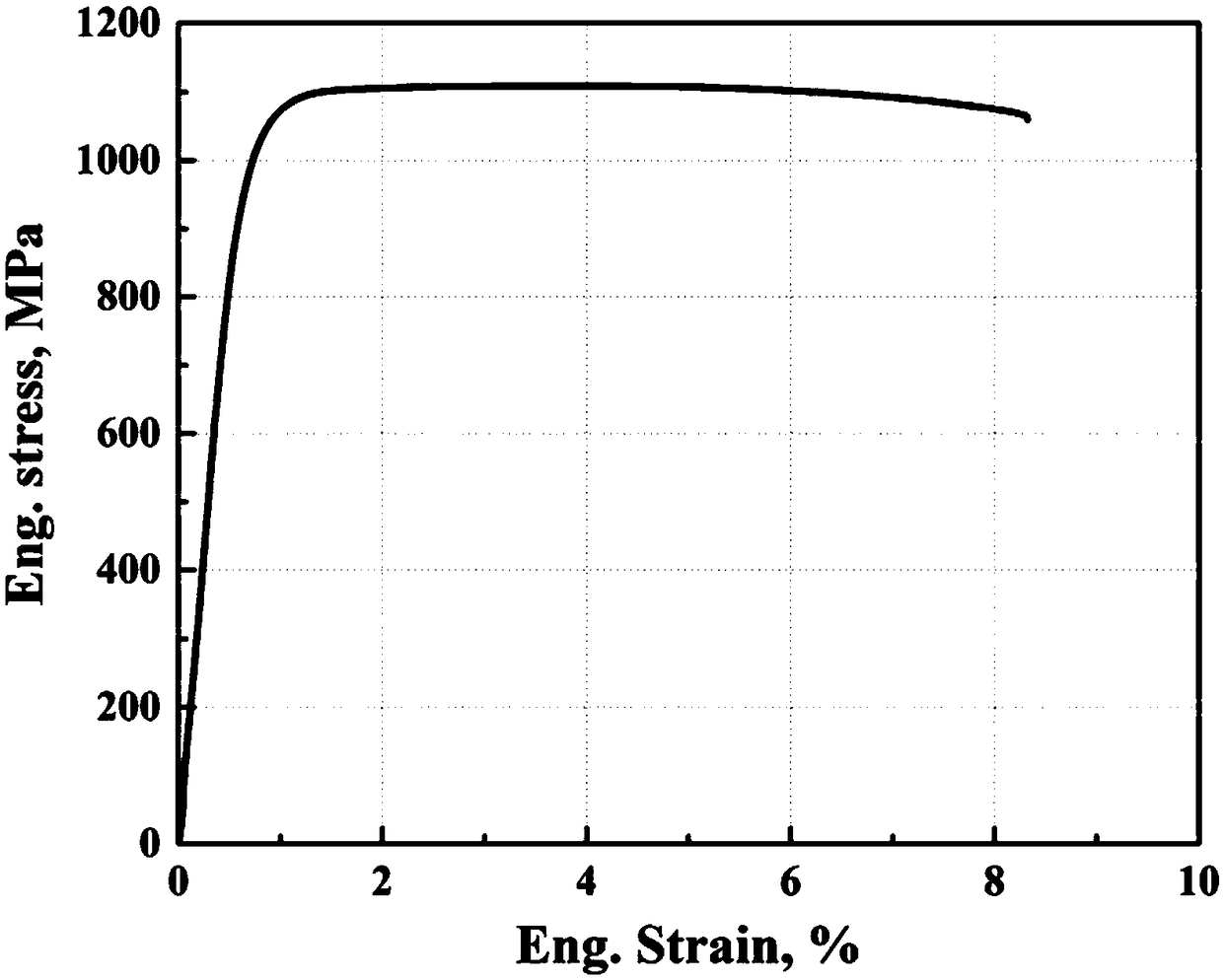

[0041] The common QAl10-4-4 aluminum-bronze alloy plate under the solid solution aging state is the preparation method of the high-strength and toughness dual-phase lamellar structure QAl10-4-4 aluminum-bronze alloy plate as initial material, and its steps are basically the same as embodiment 2, different The difference is that step 1 is omitted. The tensile strength of the obtained plate exceeds 1100MPa, the yield strength exceeds 900MPa, and the elongation at break is close to 8.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com