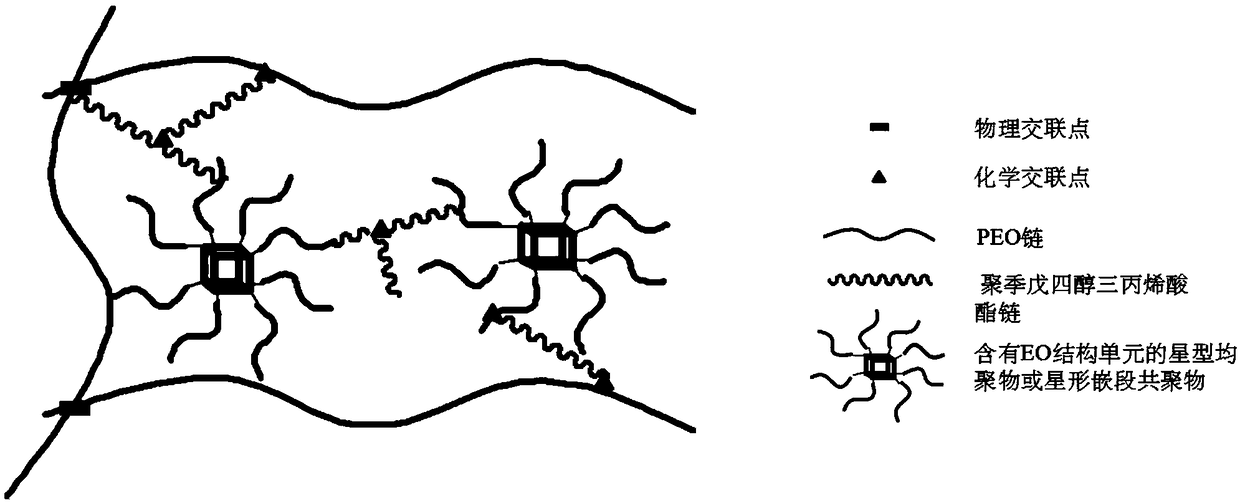

A controllable light-curable PEG solid-state topology polymer electrolyte and preparation method thereof

A topology and polymer technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of poor polymer fluidity, film formation and mechanical properties, and achieve good ionic conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

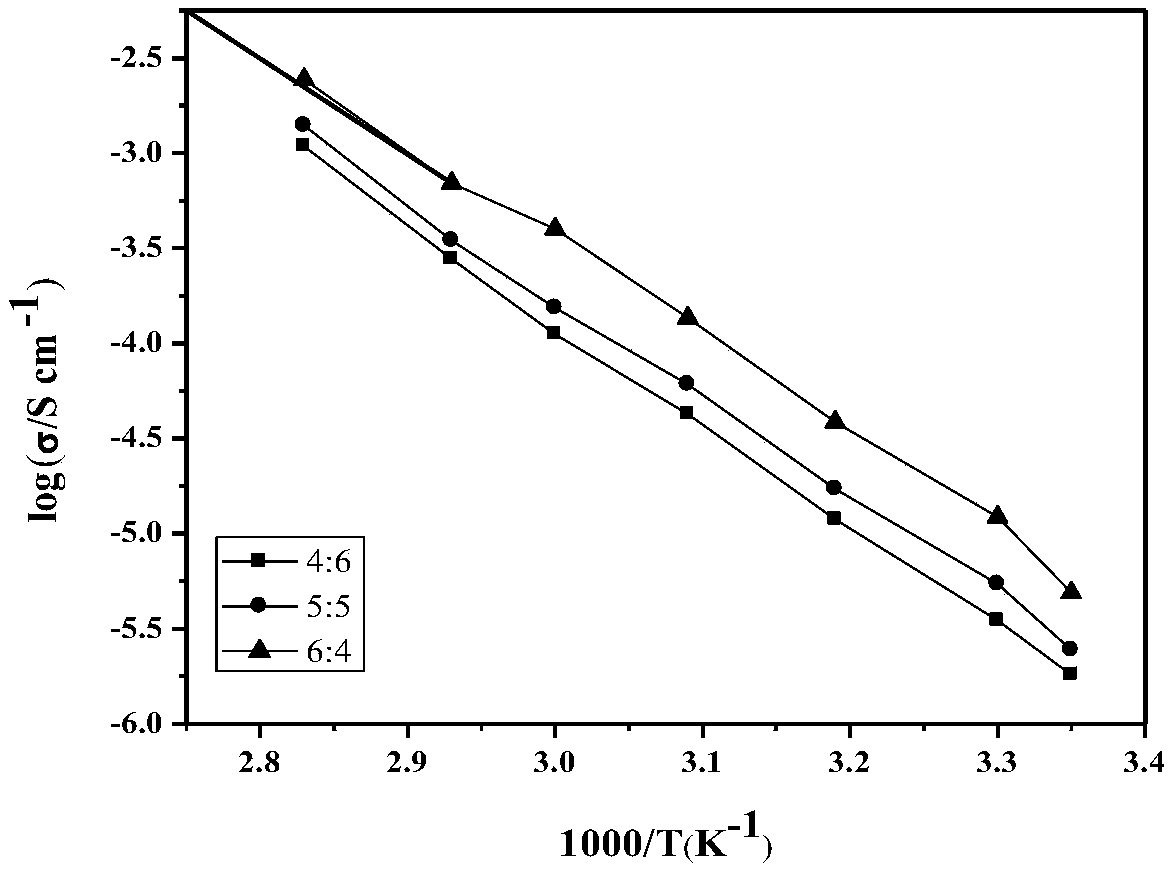

Embodiment 1

[0035] Step 1: LiClO 4 , 400WPEO, POSS-(PEG2000) 8 They were dried in a vacuum oven at 90°C, 60°C, and 55°C for 24 hours, respectively, and placed in a glove box for later use.

[0036] Step 2: Weigh PEO and POSS-(PEG2000) according to the mass ratio of 60:40, 50:50, and 40:60 respectively 8 , weigh LiClO according to the EO:Li molar ratio of 16:1 4 , weigh PETA according to 0.5wt% of the total mass of the polymer, place the weighed medicine in a sample bottle, add acetonitrile whose mass is 18 times the total mass of the polymer, and magnetically stir at room temperature for 24 hours in the dark.

[0037] Step 3: Pour the solution into a polytetrafluoroethylene petri dish, place it in a vacuum oven and evacuate it for 3 times to remove air bubbles, then volatilize at room temperature to remove the solvent.

[0038] Step 4: Adjust the distance between the UV mercury lamp and the petri dish to 10cm. After 40 minutes of UV irradiation, tear off the film and then irradiate the...

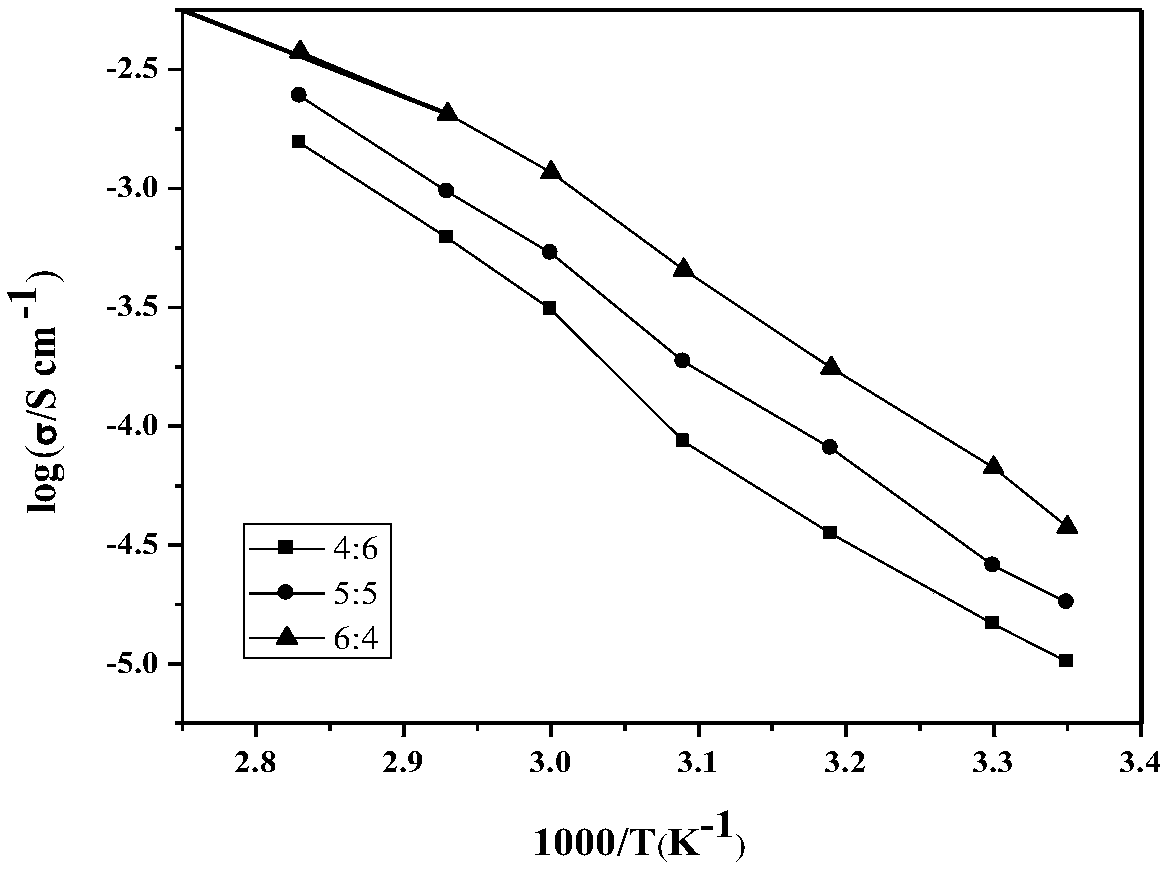

Embodiment 2

[0040] Step 1: Combine LiDFOB, 100WPEO, POSS-(PEG5000) 8 They were dried in a vacuum oven at 90°C, 60°C, and 55°C for 24 hours, respectively, and placed in a glove box for later use.

[0041]Step 2: Weigh PEO and POSS-(PEG5000) according to the mass ratio of 30:70 8 , weigh LiDFOB according to the EO:Li molar ratio of 16:1, weigh PETA according to 1wt% of the total mass of the polymer, place the weighed medicine in a sample bottle, add acetonitrile to 20 times the total mass of the polymer Then, magnetically stir at room temperature for 24 h in the dark.

[0042] Step 3: Pour the solution into a polytetrafluoroethylene petri dish, place it in a vacuum oven and evacuate it for 3 times to remove air bubbles, then volatilize at room temperature to remove the solvent.

[0043] Step 4: Adjust the distance between the UV mercury lamp and the petri dish to 8cm. After irradiating with UV light for 30 minutes, tear off the film and then irradiate the reverse side of the film with UV ...

Embodiment 3

[0045] Step 1: LiClO 4 , 60WPEO, POSS-(PMMA-PEG2000) 8 They were dried in a vacuum oven at 90°C, 60°C, and 55°C for 24 hours, and placed in a glove box for later use.

[0046] Step 2: Weigh PEO and POSS-(PMMA-PEG2000) according to the mass ratio of 50:50 8 , weigh LiClO according to the EO:Li molar ratio of 16:1 4 , weigh PETA according to 2wt% of the total mass of the polymer, put the weighed medicine in the sample bottle, add the mixed solvent (acetonitrile accounts for 30wt%, tetrahydrofuran accounts for 70%) after the quality is 18 times of the total mass of the polymer, Stir magnetically at room temperature for 18 h in the dark.

[0047] Step 3: Pour the solution into a polytetrafluoroethylene petri dish, place it in a vacuum oven and evacuate it for 3 times to remove air bubbles, then volatilize at room temperature to remove the solvent.

[0048] Step 4: Adjust the distance between the UV lamp and the petri dish to 6cm. After 20 minutes of UV irradiation, tear off th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com