A preparation method of lithium ion using inorganic perovskite derivative phase as negative electrode material

A negative electrode material, inorganic calcium technology, applied in the field of lithium ion battery negative electrode material preparation, can solve the problems of low cost, high energy density, high cost, poor cycle performance of electrodes, etc., and achieve excellent physical and chemical properties and good thermodynamic stability , suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

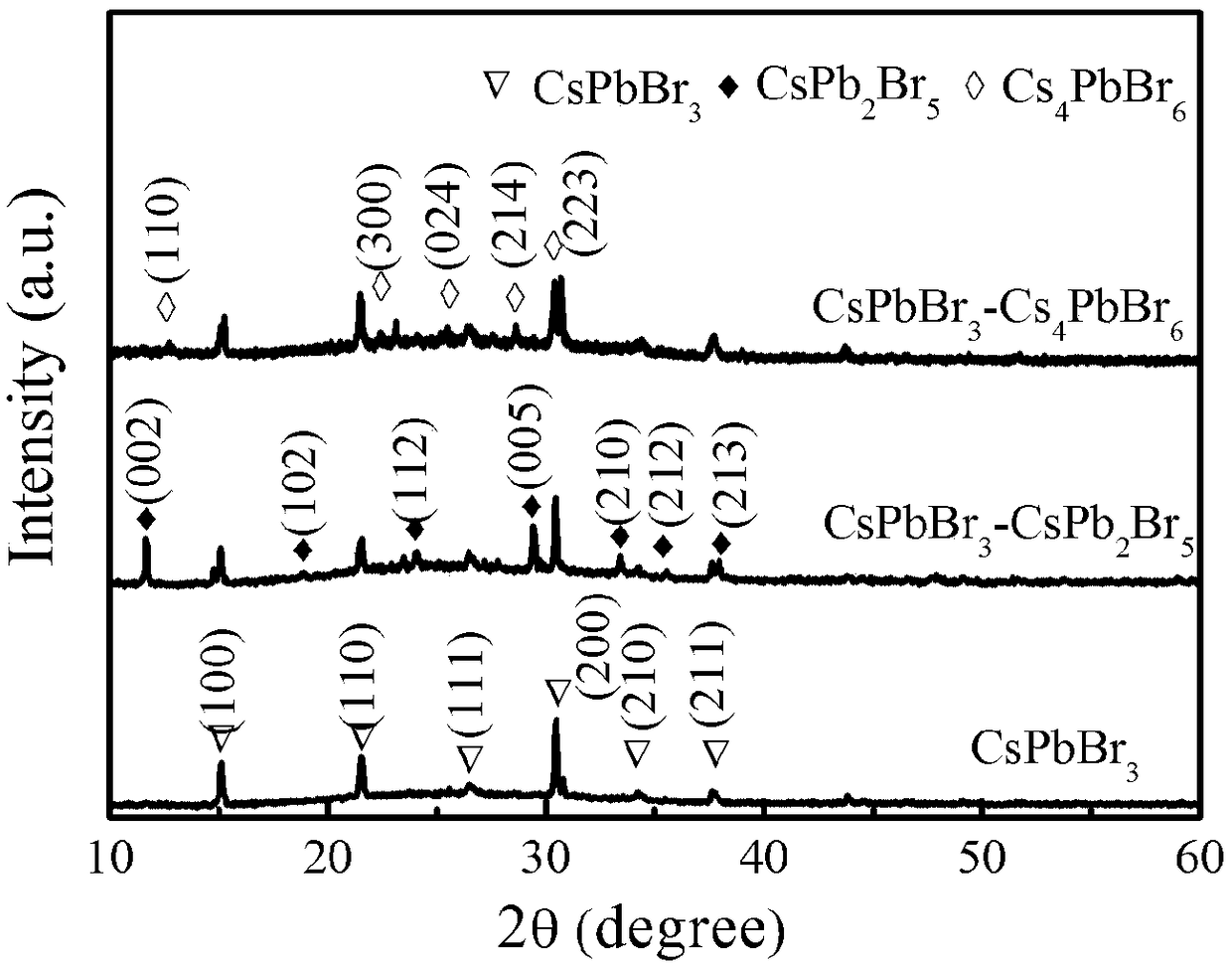

[0020] A kind of lithium ion that the present invention proposes uses the inorganic perovskite derivative phase as the preparation method of negative electrode material, comprises the following steps:

[0021] S1. Weigh a certain amount of lead bromide and cesium bromide powder, place them on the two heating devices of the vacuum system respectively, and paste the current collector copper foil on the tray above the heating device;

[0022] S2. The vacuum degree of the evaporation system is pumped to 10 -3 Pa, thermal evaporation deposition begins. First turn on the film thickness meter, and heat the burning boat (heating source) filled with cesium bromide to start monitoring the film thickness. After several hours of reaction, turn off the cesium bromide heating source, turn on the lead bromide heating source, and switch the parameters of the film thickness meter at the same time to start monitoring the lead bromide film thickness. After several hours of heating and evapora...

Embodiment 2

[0026] A kind of lithium ion that the present invention proposes uses the inorganic perovskite derivative phase as the preparation method of negative electrode material, comprises the following steps:

[0027] S1. Weigh a certain amount of lead bromide and cesium bromide powder, place them on the two heating devices of the vacuum system respectively, and paste the current collector copper foil on the tray above the heating device;

[0028] S2. The vacuum degree of the evaporation system is pumped to 10 -3 Pa, thermal evaporation deposition begins. First turn on the film thickness meter, and simultaneously heat the burning boat (heating source) containing cesium bromide and lead bromide, and start monitoring the film thickness of cesium bromide and lead bromide. After reacting for 5 hours, turn off the heating source of cesium bromide and lead bromide; the thickness of the evaporated cesium bromide is about 10 μm, and the thickness of lead bromide is about 5 μm.

[0029] S3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com