Sulfosalicylic acid silver plated additive, preparation method of sulfosalicylic acid silver plated additive and electroplating liquid including sulfosalicylic acid silver plated additive

A technology of sulfosalicylic acid and additives, which is applied in the field of sulfosalicylic acid silver plating additives, can solve the problems of large damage to the health of operators, unfavorable environmental protection of sewage, uneven silver plating layer, etc., and achieves improved flatness, Low brittleness and good discoloration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

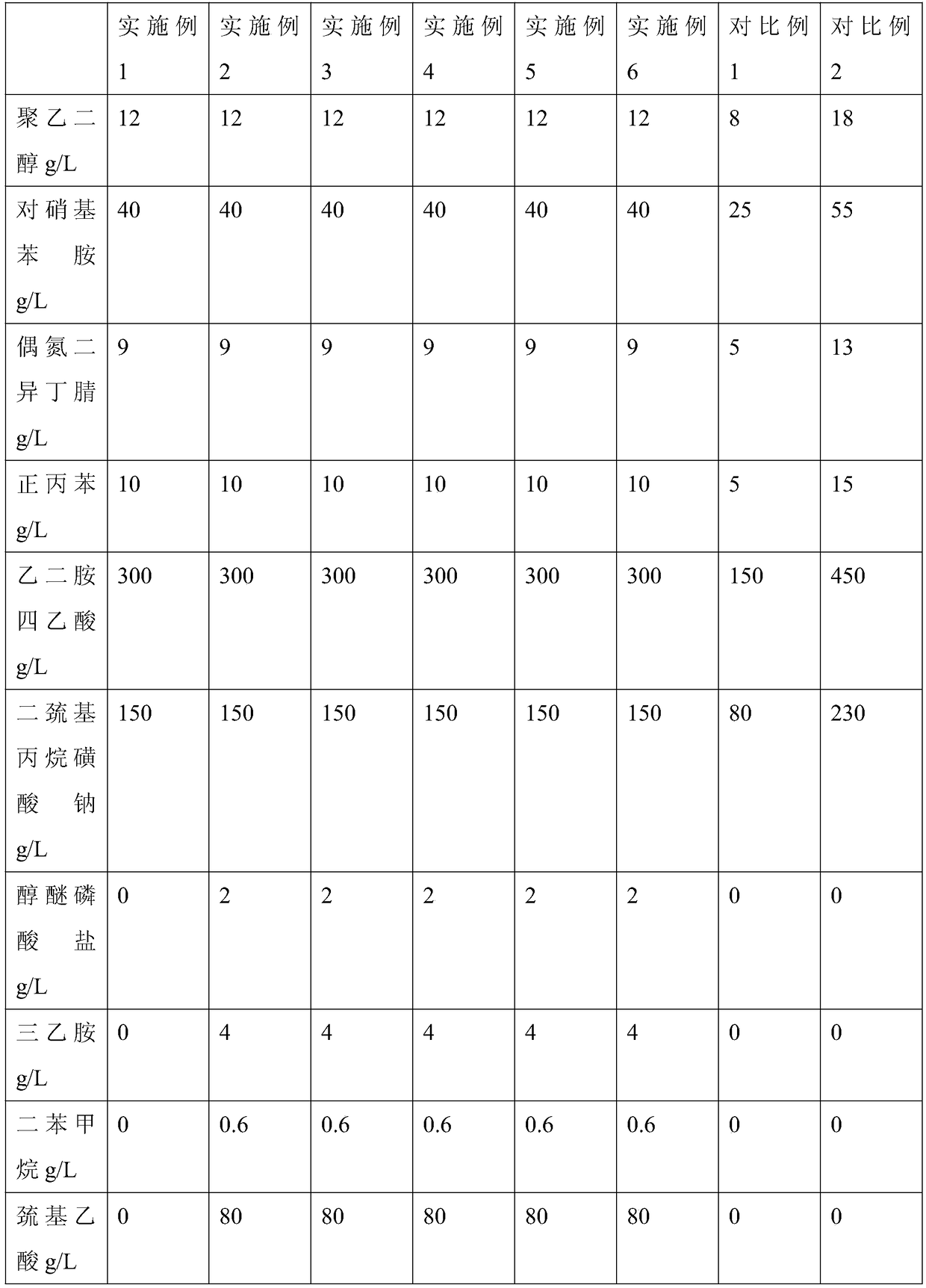

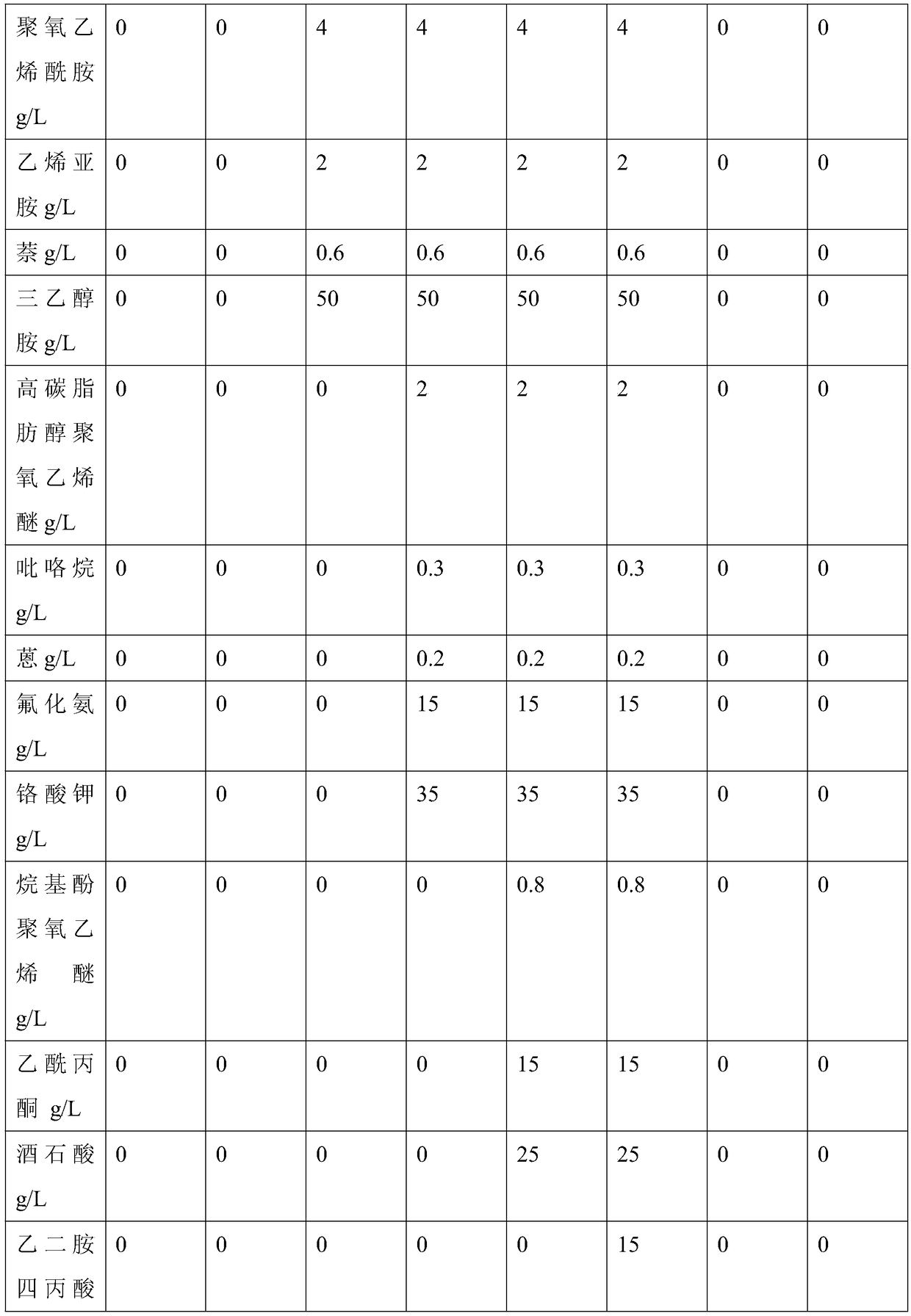

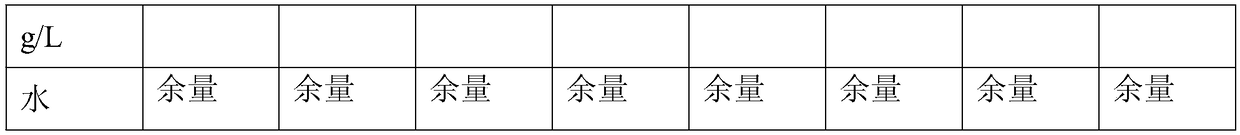

[0040] The preparation method of the sulfosalicylic acid silver plating additive of above-mentioned each example, comprises the steps:

[0041] 1) Heat the water to 80-90°C, under stirring at 1100r / min, add polyethylene glycol, alcohol ether phosphate, polyoxyethylene amide, high-carbon fatty alcohol polyoxyethylene ether and alkylphenol polyoxygen After vinyl ether, continue stirring at 80-90°C, 1100r / min for 25min;

[0042] 2) Add ethylenediaminetetraacetic acid, sodium dimercaptopropanesulfonate, mercaptoacetic acid, triethanolamine, ammonium fluoride, potassium chromate, acetylacetone, tartaric acid and ethylenediaminetetrapropionic acid to the material obtained in step 1) in sequence , and then stirred at 80-90°C and 1100r / min for 15min;

[0043] 3) adding p-nitroaniline, azobisisobutyronitrile, triethylamine, ethyleneimine, pyrrolidine, n-propylbenzene, diphenylmethane, naphthalene and anthracene to the material obtained in step 2) successively, then at 80 Stir at -90°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com