Novel vacuum insulated panel and preparation and application thereof

A vacuum insulation panel and a new type of technology, applied in the field of building insulation materials, can solve the problems affecting application and promotion, poor use effect, serious thermal bridge effect, etc., and achieve the effects of excellent mechanical properties, small thermal weight loss, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

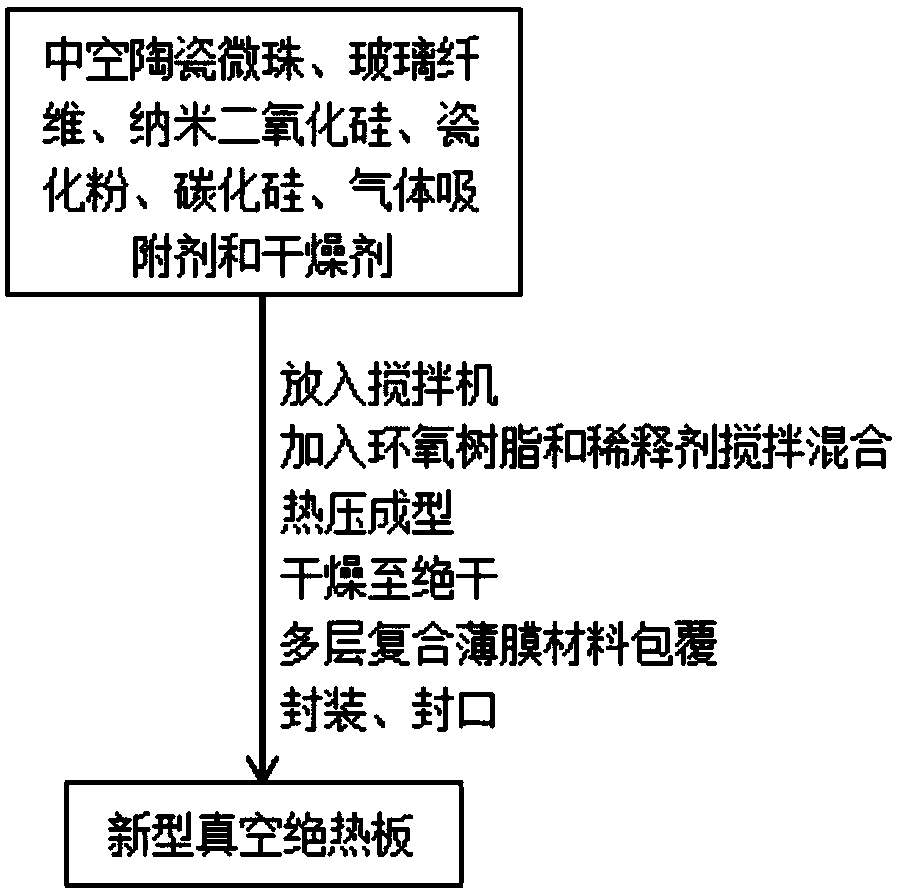

[0026] Example 1 Preparation of novel vacuum insulation panel

[0027] Core material composition: 50 parts of hollow ceramic microbeads, 40 parts of glass fiber, 20 parts of nano-silica, 6 parts of low-temperature glass powder, 12 parts of montmorillonite, 12 parts of magnesium oxide, 10 parts of silicon carbide, and 10 parts of alumina and 5 parts of anhydrous calcium chloride;

[0028] Preparation of multilayer composite film material: It is formed by laminating 0.01mm polyetheretherketone film and 0.01mm polyester base film, each layer of film is fixed with ethylenediamine, and the thickness of the obtained multilayer composite film material is 0.1mm;

[0029] Preparation of new vacuum insulation panels: Weigh hollow ceramic microbeads, glass fibers, nano-silica, low-temperature glass powder, montmorillonite, magnesium oxide, silicon carbide, aluminum oxide and anhydrous calcium chloride in proportion and put them into a well-sealed In a blender, add an equal amount of ep...

Embodiment 2

[0030] Example 2 Preparation of novel vacuum insulation panel

[0031] Core material composition: 70 parts of hollow ceramic microbeads, 60 parts of glass fiber, 30 parts of nano-silica, 6 parts of magnesium hydroxide, 24 parts of mica powder, 24 parts of kaolin, 20 parts of silicon carbide, 15 parts of natural clay and Mongolia 20 parts of de-stoned;

[0032] Preparation of multilayer composite film material: It is formed by laminating 0.02mm polyetheretherketone film and 0.02mm polyester base film, each layer of film is fixed with diethylenetriamine, and the thickness of the obtained multilayer composite film material is 0.14mm;

[0033]Preparation of new vacuum insulation panels: Weigh hollow ceramic microbeads, glass fibers, nano-silica, magnesium hydroxide, mica powder, kaolin, silicon carbide, natural clay and montmorillonite in proportion to a well-sealed mixer, Add an equal amount of epoxy resin and diluent (hollow ceramic microbeads 5%) for stirring and mixing with ...

Embodiment 3

[0034] Example 3 Preparation of novel vacuum insulation panel

[0035] Core material composition: 70 parts of hollow ceramic microbeads, 47 parts of glass fiber, 25 parts of nano-silica, 5 parts of aluminum hydroxide, 15 parts of diatomaceous earth, 15 parts of potassium oxide, 15 parts of silicon carbide, 12 parts of molecular sieve and 6 parts of phosphorus pentoxide, 6 parts of anhydrous calcium chloride;

[0036] Preparation of multi-layer composite film material: It is formed by laminating 0.01-0.02mm polyetheretherketone film and 0.01-0.02mm polyester base film, each layer of film is fixed with a curing agent, and the obtained multi-layer composite film Material thickness is 0.1-0.15mm;

[0037] Preparation of new vacuum insulation panels: weigh hollow ceramic microbeads, glass fibers, nano-silica, aluminum hydroxide, diatomaceous earth, potassium oxide, silicon carbide, molecular sieves, phosphorus pentoxide, anhydrous calcium chloride Put it into a well-sealed mixer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com