Inorganic sandwich composite external thermal insulation system

A composite technology for external wall thermal insulation, applied in the direction of hydraulic material layered products, covering/lining, layered products, etc., can solve the problems of complicated manufacturing process, large deformation coefficient, poor safety, etc. Wide range, excellent crack resistance, strong wind pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

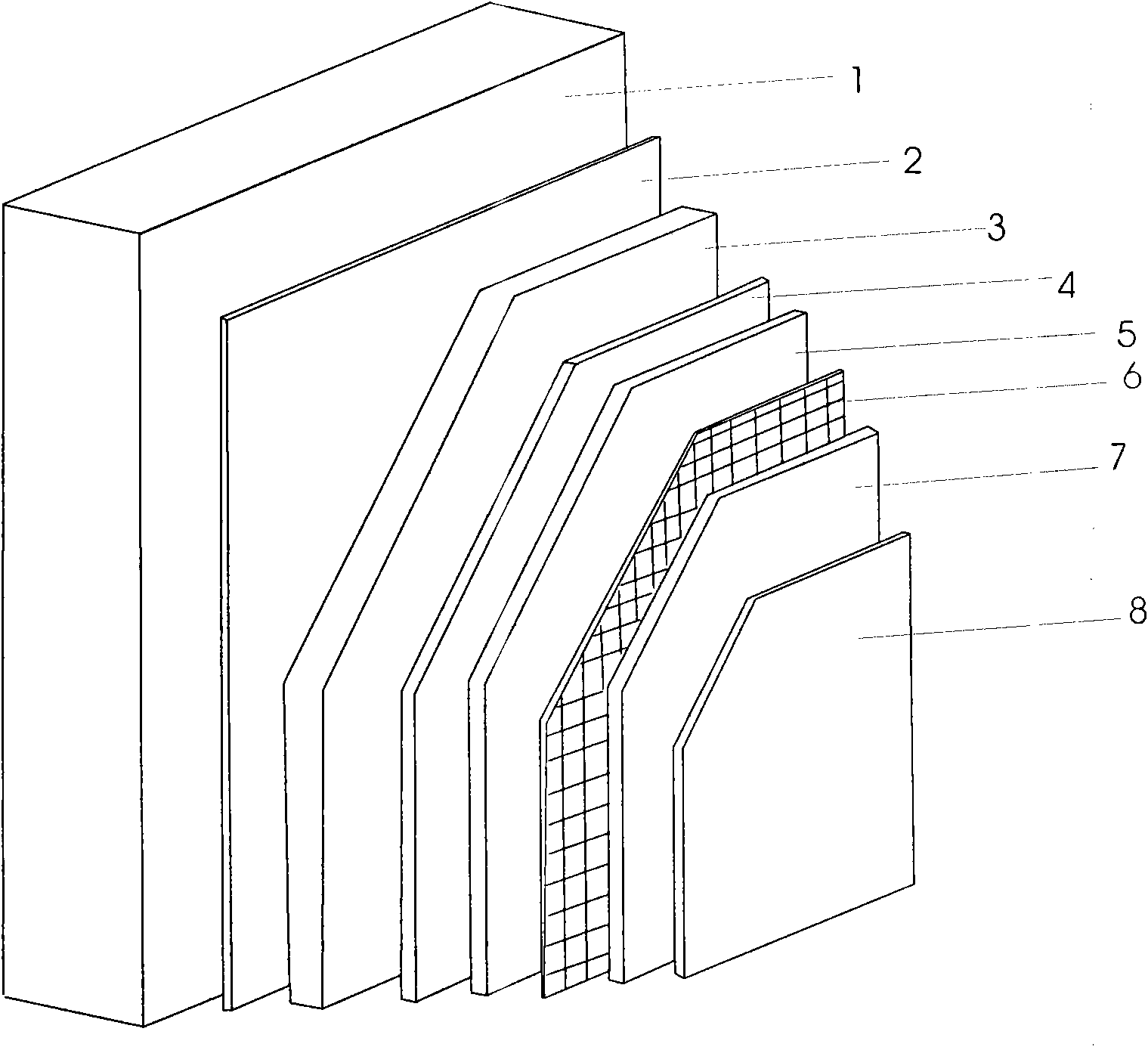

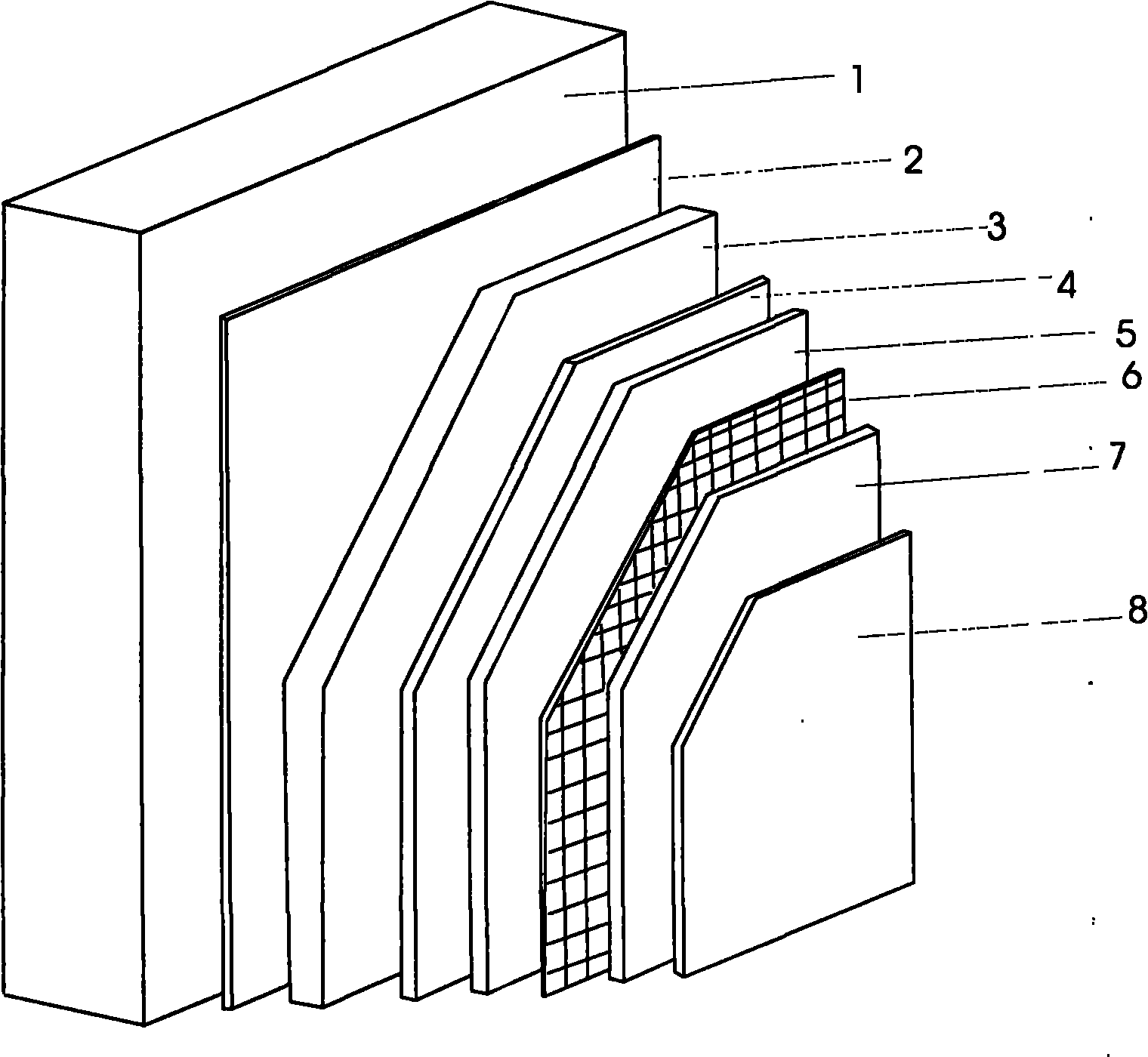

[0023] Such as figure 1 As shown, an inorganic light aggregate thermal insulation mortar sticking inorganic fiber cotton thermal insulation board sandwich composite external wall thermal insulation system includes a base wall 1, an inorganic light aggregate thermal insulation mortar bonding layer 2, and an inorganic fiber cotton thermal insulation board layer 3 , Inorganic light aggregate thermal insulation mortar bonding leveling layer 4, polymer anti-cracking mortar protective layer 5, alkali-resistant glass fiber mesh cloth 6, polymer anti-cracking mortar protective layer 7, paint or dry-hanging finish layer 8. In the specific implementation process, the inorganic fiber cotton insulation board layer 3 can use any one of several inorganic fiber cotton boards such as hydrophobic (non-hydrophobic) rock wool boards or hydrophobic (non-hydrophobic) glass wool boards.

[0024] The construction process of inorganic fiber cotton insulation board sandwich composite exterior wall ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com