Surface treatment method capable of improving aluminium alloy corrosion resistance

A surface treatment and corrosion-resistant technology, used in metal material coating technology, metal processing equipment, surface reaction electrolytic coating, etc., to achieve low cost, ensure durability, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

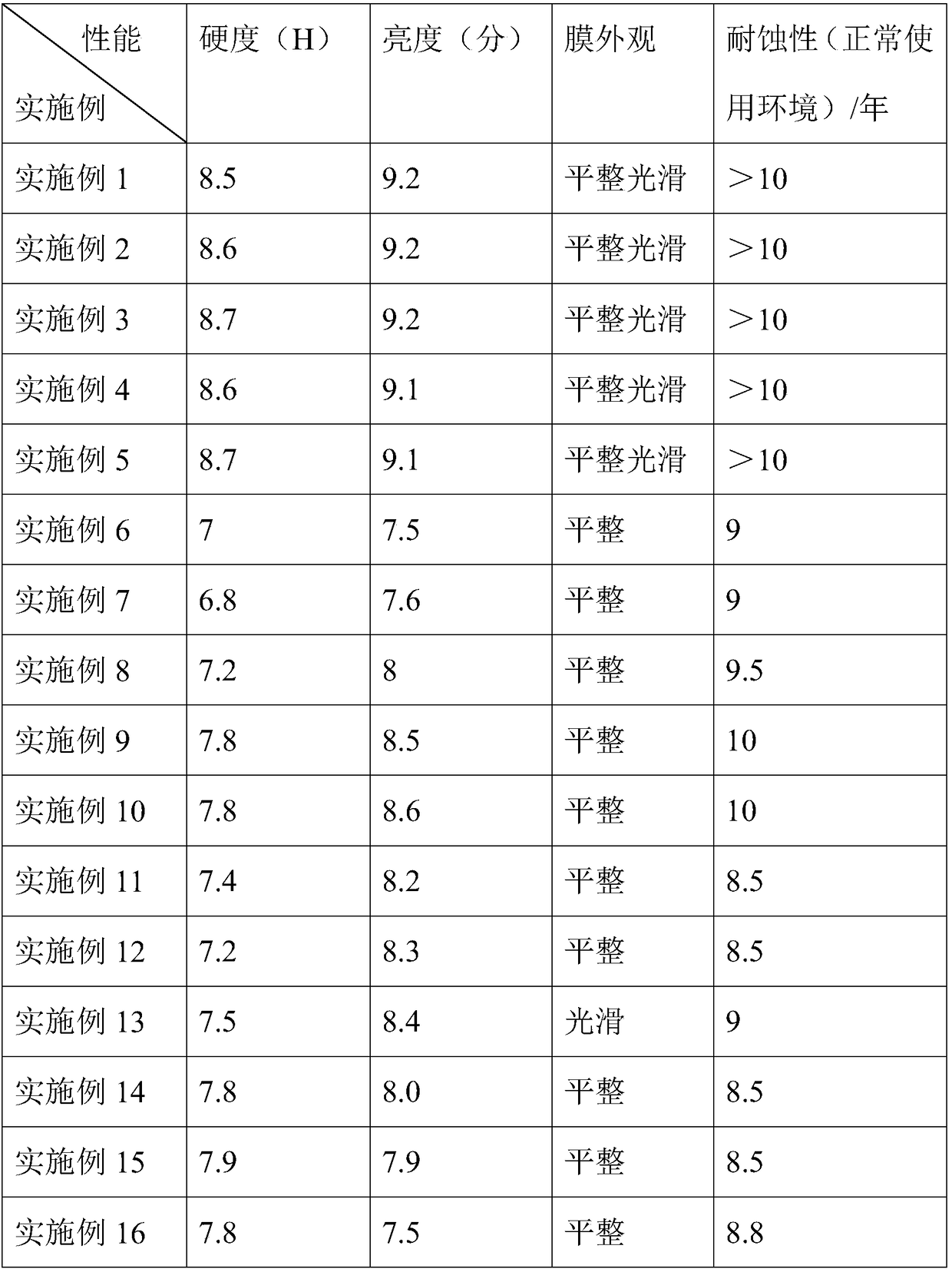

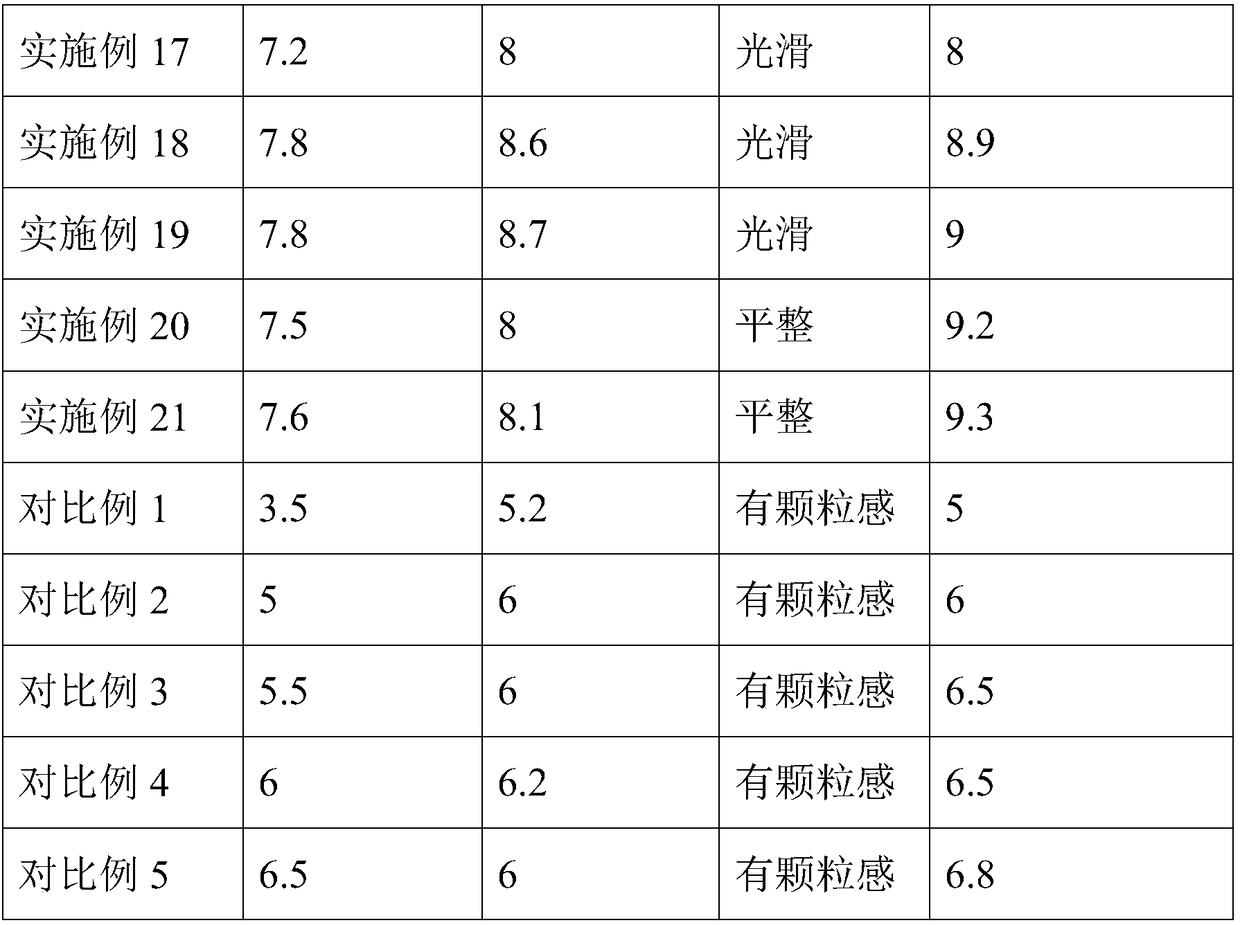

Examples

Embodiment 1

[0026] Pretreatment: Degreasing and degreasing, ultrasonic cleaning, electrochemical polishing, and soft abrasive flow polishing are performed on aluminum alloy workpieces in sequence. Wherein, the electrochemical polishing solution comprises the following components in mass percentage: 30% sulfuric acid, 60% phosphoric acid, 3% deionized water, 3% ethanol, 1.8% urea, 0.2% benzotriazole, 1.5% glycerin; The voltage value of polishing is required to be 28V, and the time is 1100s; the abrasive particles in the process of soft abrasive flow polishing are nano-zirconia, and the abrasive particle size is 0.1nm;

[0027]Platinization treatment: Platinization solution for platinum treatment is: tetrafluoroplatinic acid 50g / L, polyethylene glycol 25g / L, carboxyethyl cellulose 25g / L, polyacrylate 20g / L; The time is 3min, the temperature is 60°C;

[0028] Anodizing treatment: The electrolyte for anodizing treatment is: sodium silicate 5g / L, oxidized dilute sulfuric acid 15g / L, sodium tu...

Embodiment 2

[0036] Pretreatment: Degreasing and degreasing, ultrasonic cleaning, electrochemical polishing, and soft abrasive flow polishing are performed on aluminum alloy workpieces in sequence. Wherein, the electrochemical polishing solution comprises the following components in mass percentage: 31% sulfuric acid, 61% phosphoric acid, 3.5% deionized water, 3.5% ethanol, 1.85% urea, 0.4% benzotriazole, 1.6% glycerin; The voltage value of polishing is required to be 30V, and the time is 1300s; the abrasive particles in the process of soft abrasive flow polishing are nano-zirconia, and the abrasive particle size is 0.2nm;

[0037] Platinization treatment: Platinization solution for platinum treatment is: tetrafluoroplatinic acid 55g / L, polyethylene glycol 26g / L, carboxyethyl cellulose 30g / L, polyacrylate 22g / L; The time is 3.5min and the temperature is 62°C;

[0038] Anodizing treatment: The electrolyte for anodizing treatment is: sodium silicate 6g / L, oxidized dilute sulfuric acid 16g / L...

Embodiment 3

[0046] Pretreatment: Degreasing and degreasing, ultrasonic cleaning, electrochemical polishing, and soft abrasive flow polishing are performed on aluminum alloy workpieces in sequence. Wherein, the electrochemical polishing solution comprises the following components in mass percentage: 33% sulfuric acid, 63% phosphoric acid, 4% deionized water, 4% ethanol, 1.9% urea, 0.6% benzotriazole, 1.8% glycerin; The voltage value of polishing is required to be 33V, and the time is 1450s; the abrasive particles in the process of soft abrasive flow polishing are nano-zirconia, and the particle size of abrasive particles is 0.3nm;

[0047] Platinization treatment: Platinization solution for platinum treatment is: tetrafluoroplatinic acid 60g / L, polyethylene glycol 28g / L, carboxyethyl cellulose 32g / L, polyacrylate 25g / L; The time is 4min, the temperature is 65°C;

[0048] Anodizing treatment: The electrolyte for anodizing treatment is: sodium silicate 8g / L, oxidized dilute sulfuric acid 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com