Light attenuation resistant PERC single crystalline silicon solar cell aluminum paste and preparation method thereof

A technology of solar cells and monocrystalline silicon, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. Reduce the photoelectric conversion efficiency and other problems to achieve the effect of reducing the light attenuation range, improving the photoelectric conversion efficiency, and enhancing the gettering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

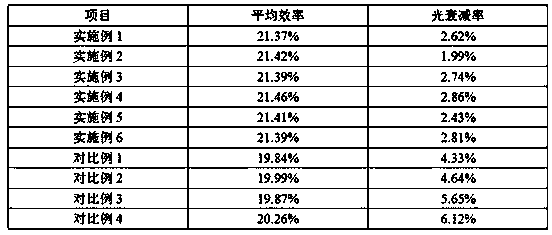

Examples

Embodiment 1

[0019] An anti-light fading aluminum paste for PERC monocrystalline silicon solar cells, the aluminum paste is made of the following components in proportion by mass: 75 parts of aluminum powder, 1.5 parts of inorganic binder, 22.5 parts of organic binder, 1 part of inorganic additives.

[0020] The inorganic auxiliary agent is indium powder with an average particle size of 2 μm and a tap density of 3.2 g / cm 3 , the specific surface area is 1.1m 2 / g.

[0021] The aluminum powder is spherical, with an average particle size of 8.6 μm and a tap density of 2.4 g / cm 3 , the specific surface area is 1.6m 2 / g.

[0022] The organic binder is composed of 35 parts of alcohol ester twelve parts by mass, 25 parts of terpineol, 14 parts of castor oil, 12 parts of tributyl citrate, 7 parts of ethyl cellulose, 4 parts of polyamide Wax, prepared from 3 parts polyether phosphate.

[0023] Described inorganic binder is 1 part of SiO by mass parts proportioning 2 , 30 parts BaCO 3 , 12...

Embodiment 2

[0029] An anti-light fading aluminum paste for PERC monocrystalline silicon solar cells, the aluminum paste is made of the following components in proportion by mass: 78 parts of aluminum powder, 1 part of inorganic binder, 19.5 parts of organic binder, 1.5 parts of inorganic additives.

[0030] The inorganic auxiliary agent is indium oxide powder with an average particle size of 1.3 μm and a tap density of 2.1 g / cm 3 , the specific surface area is 1.8m 2 / g.

[0031] The aluminum powder is spherical, with an average particle size of 9.2 μm and a tap density of 2.8 g / cm 3 , with a specific surface area of 1.3m 2 / g.

[0032] The organic binder is composed of 39 parts of alcohol ester twelve parts by mass, 26 parts of terpineol, 10 parts of castor oil, 10 parts of tributyl citrate, 5 parts of ethyl cellulose, 4 parts of polyamide Wax, prepared from 6 parts polyether phosphate.

[0033] Described inorganic binder is 1 part of SiO by mass parts proportioning 2 , 26 parts B...

Embodiment 3

[0039] An anti-light fading aluminum paste for PERC monocrystalline silicon solar cells, the aluminum paste is made of the following components in proportion by mass: 80 parts of aluminum powder, 1.5 parts of inorganic binder, 18 parts of organic binder, 0.5 parts of inorganic additives.

[0040] The inorganic auxiliary agent is indium powder with an average particle size of 0.4 μm and a tap density of 1.5 g / cm 3 , the specific surface area is 2.3m 2 / g.

[0041] The aluminum powder is spherical, with an average particle size of 10 μm and a tap density of 3.3 g / cm 3 , the specific surface area is 0.9m 2 / g.

[0042] The organic binder is composed of 32 parts of alcohol ester twelve parts by mass, 15 parts of terpineol, 15 parts of castor oil, 15 parts of tributyl citrate, 10 parts of ethyl cellulose, and 8 parts of polyamide Wax, prepared from 5 parts polyether phosphate.

[0043] Described inorganic binder is 4 parts of SiO by mass parts proportioning 2 , 15 parts BaCO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com