Circuit board with side metal structure and method of making the same

A metal structure, circuit board technology, applied in the direction of printed circuit manufacturing, printed circuits, printed circuit components, etc., can solve the problems of burr residue, affecting reliability and appearance, and achieve the effect of improving product reliability and improving product appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

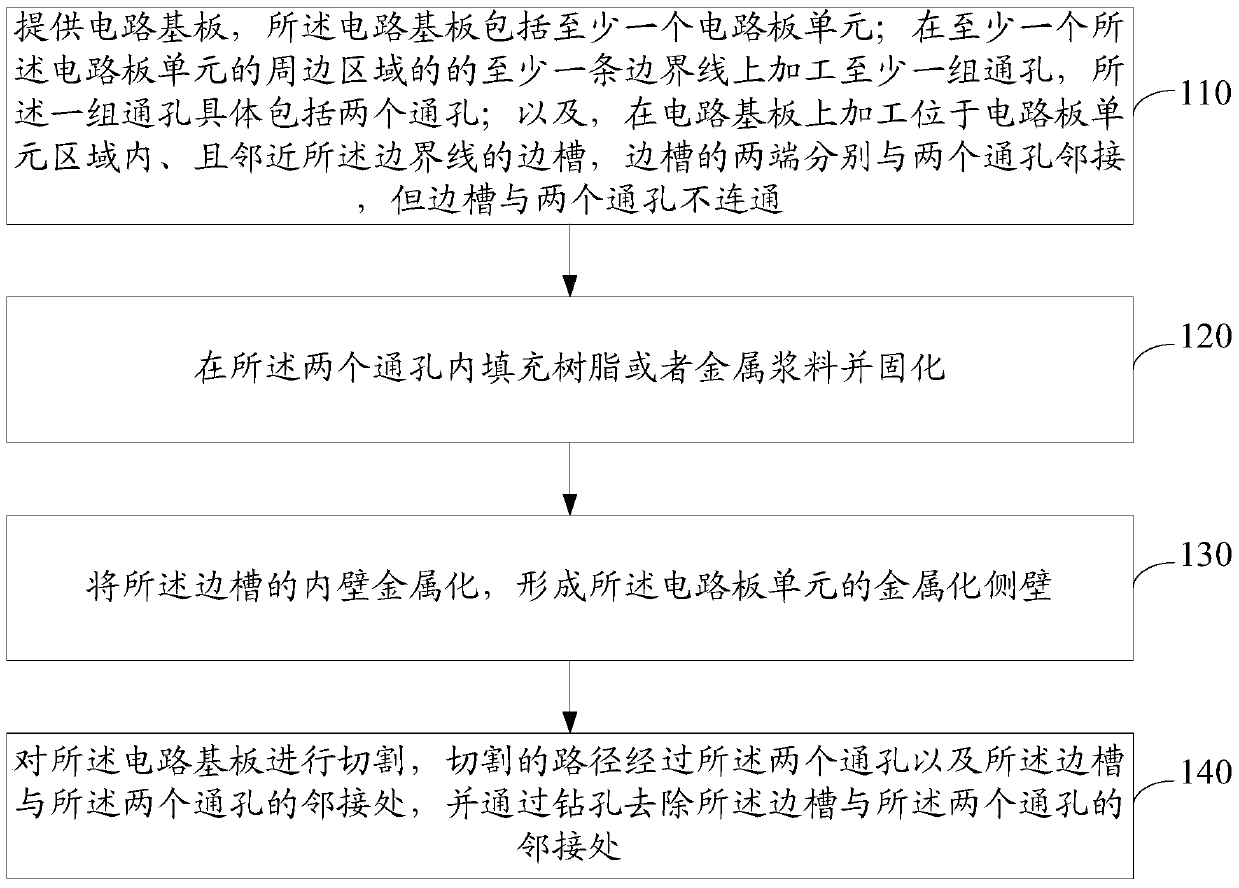

[0025] Please refer to figure 1 , an embodiment of the present invention provides a method for manufacturing a circuit board with a side metal structure, which may include:

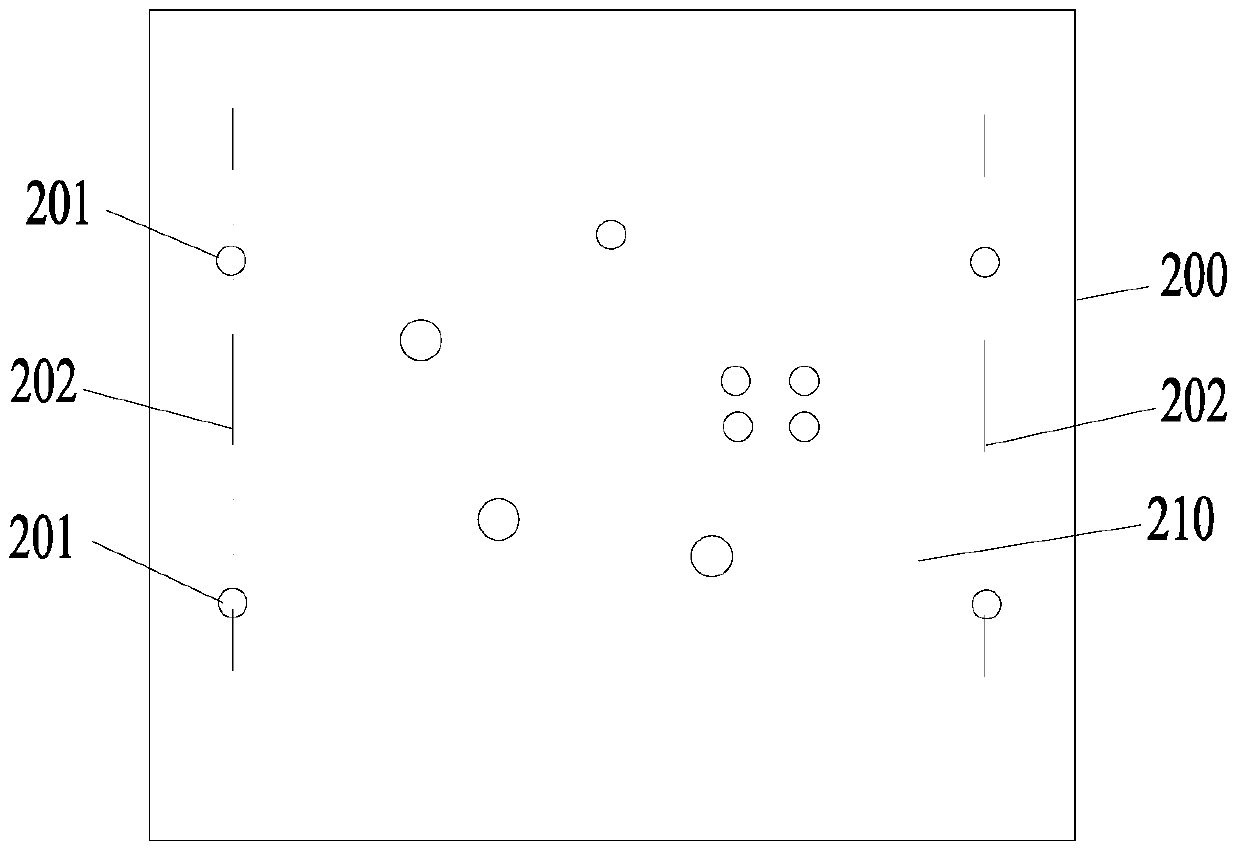

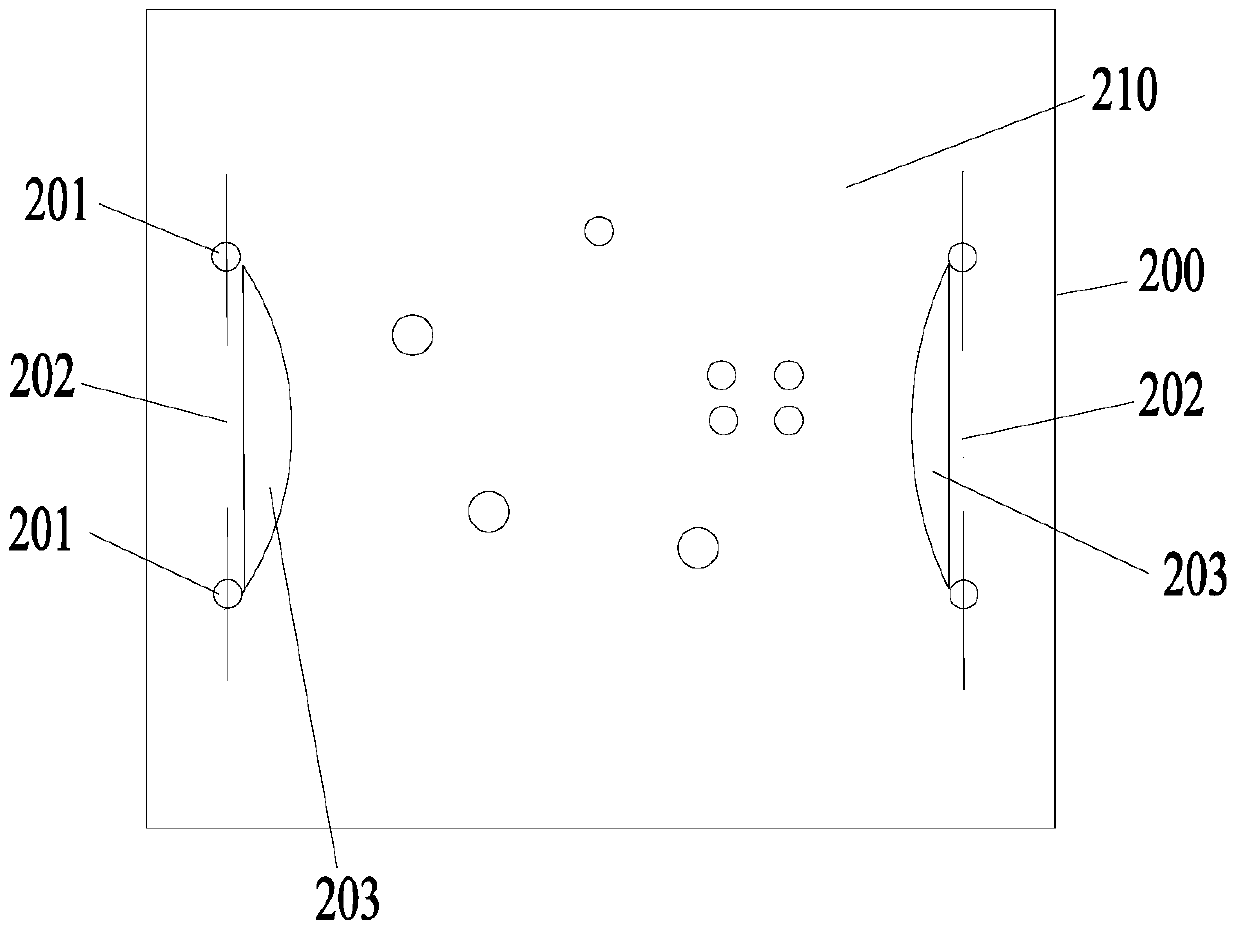

[0026] 110. A circuit substrate is provided, and the circuit substrate includes at least one circuit board unit; at least one set of through holes is processed on at least one boundary line of the peripheral area of at least one of the circuit board units, and the set of through holes specifically includes two through holes; and, processing a side groove located in the circuit board unit area and adjacent to the boundary line on the circuit substrate, the two ends of the side groove are respectively adjacent to the two through holes, but the side groove is adjacent to the two through holes Not connected.

[0027] In the embodiment of the present invention, the circuit substrate may be a copper-clad laminate or a multi-layer laminate based on the copper-clad laminate, and the copper-clad laminate may be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com