Large-sized, high-strength and high-toughness 7000 series aluminum alloy round cast ingot and preparation method thereof

A high-strength, high-toughness, aluminum alloy technology, applied in the field of 7000 series aluminum alloy round ingots and their preparation, can solve problems such as poor strength and fracture toughness, and achieve the advantages of increasing strength, reducing flux usage, and improving melt purification effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

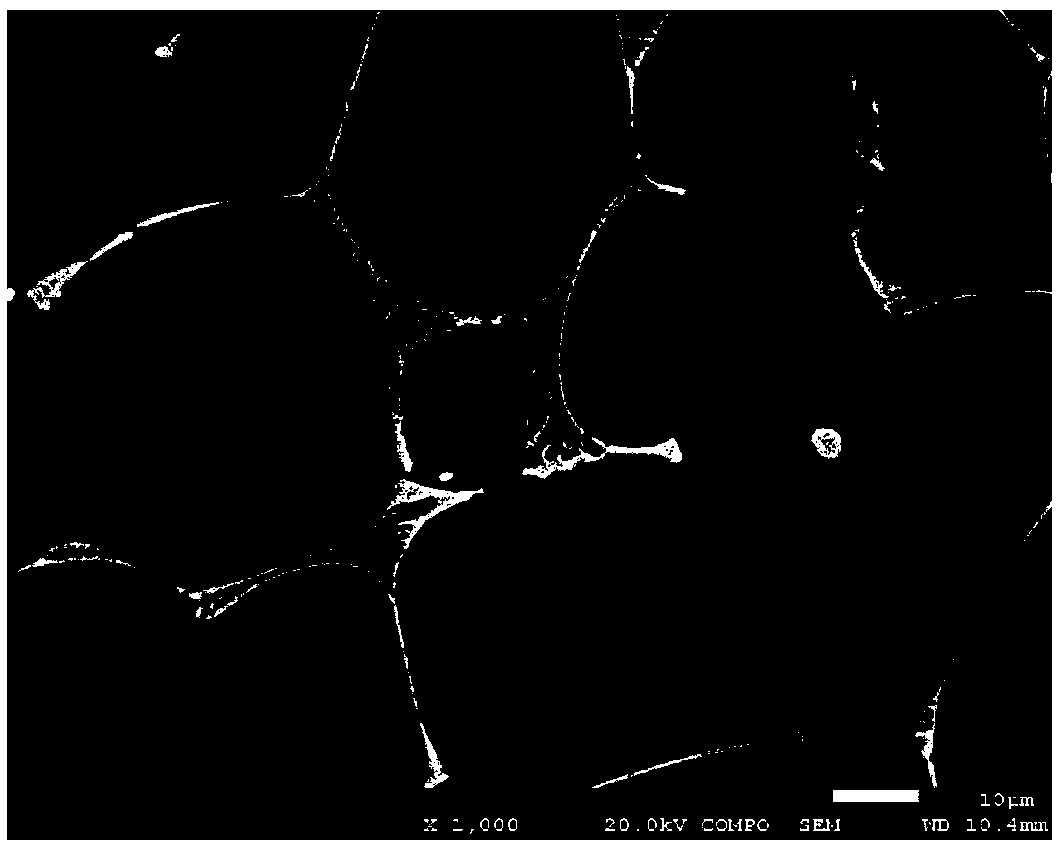

Image

Examples

specific Embodiment approach 1

[0069] Specific Embodiment 1: In this embodiment, the large-scale 7000 series high-strength aluminum alloy round ingot is composed of Si≤0.01%, Fe≤0.01%, Cu: 1.9%-2.5%, Mn: 0.2%-0.6%, Mg: 1.8% ~2.5%, Cr: 0.03%~0.05%, Zn: 8.4%~9.4%, Ti≤0.10%, Zr: 0.15%~0.22%, Sb: 0.03%~0.05%, Be: 0.00045%~0.0012%, Na The total amount of +Li+K≤5ppm and the balance of Al are made.

[0070] The mechanical properties of Al-Zn-Mg-Cu alloys mainly depend on the content of Zn and Mg, and MgZn with remarkable strengthening effect can be formed. 2 Phase, as the content of Zn and Mg increases, the strength of the alloy increases significantly, and the tensile strength and heat treatment effect generally increase accordingly. However, its resistance to stress corrosion and exfoliation corrosion will decrease accordingly.

[0071] The present invention can further increase the strength of the alloy and improve the castability of the alloy by appropriately adding the microalloying element Mn element, appr...

specific Embodiment approach 2

[0073] Specific implementation mode two: the preparation method of the large-scale 7000 series high-strength aluminum alloy round ingot in this implementation mode includes the following steps:

[0074] 1. By weight percentage Si≤0.01%, Fe≤0.01%, Cu: 1.9%~2.5%, Mn: 0.2%~0.6%, Mg: 1.8%~2.5%, Cr: 0.03%~0.05%, Zn: 8.4 %~9.4%, Ti≤0.10%, Zr: 0.15%~0.22%, Sb: 0.03%~0.05%, Be: 0.00045%~0.0012%, the total amount of Na+Li+K≤5ppm and the balance Al to weigh the ingredients The ingredients are aluminum ingots, copper plates, magnesium ingots, zinc ingots, electrolytic manganese metal, aluminum alloy waste, aluminum titanium boron wire, powdered aluminum zirconium master alloy, aluminum beryllium master alloy, aluminum antimony master alloy, the aluminum alloy The waste material is an aluminum alloy of the same type as the aluminum alloy to be prepared; the aluminum ingot is a refined aluminum ingot;

[0075] 2. Sprinkle a layer of flux evenly on the bottom of the smelting furnace before...

specific Embodiment approach 3

[0085] Embodiment 3: This embodiment differs from Embodiment 2 in that: the content of Fe in the refined aluminum ingot in step 1 is less than 0.005, the content of Si is less than 0.005, and the content of Na+Li+K alkali metals is less than 5 ppm. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Longitudinal tensile strength | aaaaa | aaaaa |

| Non-proportional tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com