A kind of cerium, terbium co-doped activated aluminosilicate luminescent phosphor and preparation method thereof

A technology of aluminosilicate and fluorescent powder, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., to achieve the effects of high emission intensity, low preparation cost and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

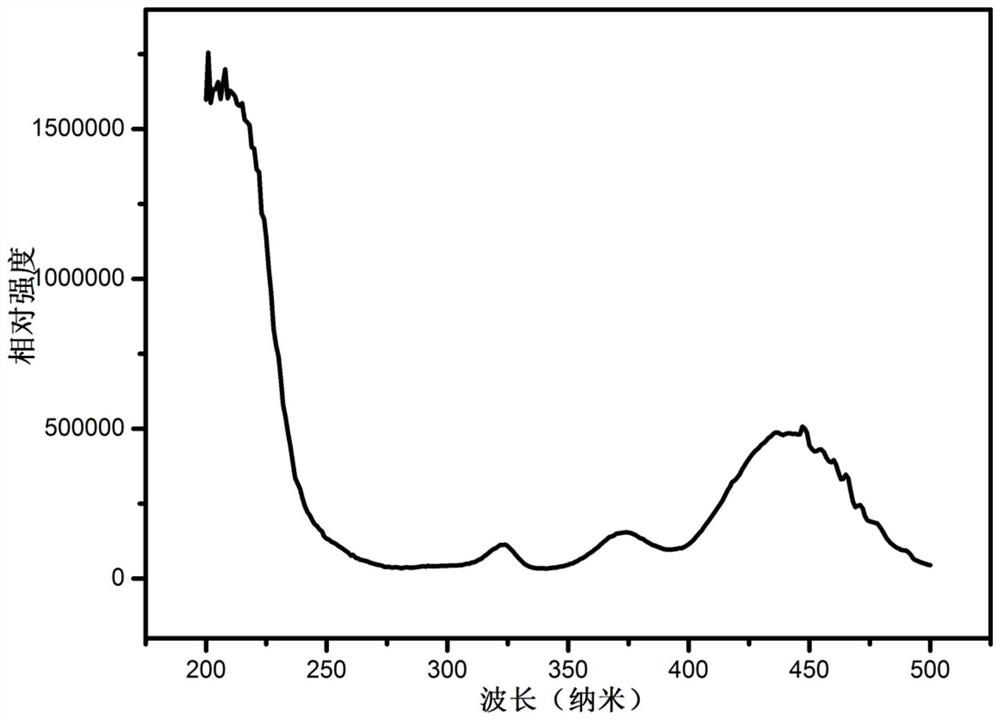

[0032] Example 1: Ca 19.96 al 26 Mg 3 Si 3 o 68 :0.2Ce 3+ ,0.2Li + ;

[0033] Weigh CaCO 3 (Analytical pure) 0.9809g, A1 2 o 3 (analytical pure) 0.6627g, MgO (analytical pure) 0.0604g, SiO 2 (Analytical pure) 0.0902g, Ce 2 (CO 3 ) 3 (99.99%) 0.0230g, Li 2 CO 3 (Analytical pure) 0.0037g. Put the above raw materials in an agate mortar, add ethanol with the same volume as the raw materials, and grind for 30 minutes to make the raw materials fully mixed. Transfer the uniformly mixed reactants into a corundum crucible, put it into a high-temperature tube furnace, and heat it under 10% (volume) H at 1350°C 2 , 90% (volume) N 2 Calcined in mixed gas for 2 hours. The reducing atmosphere in the high-temperature tube furnace was lowered to room temperature, and the calcined block sample was ground into powder in an agate mortar to obtain the required phosphor powder with a mass of 1.3877g. The sample emitted blue light under a 365nm ultraviolet lamp.

Embodiment 2

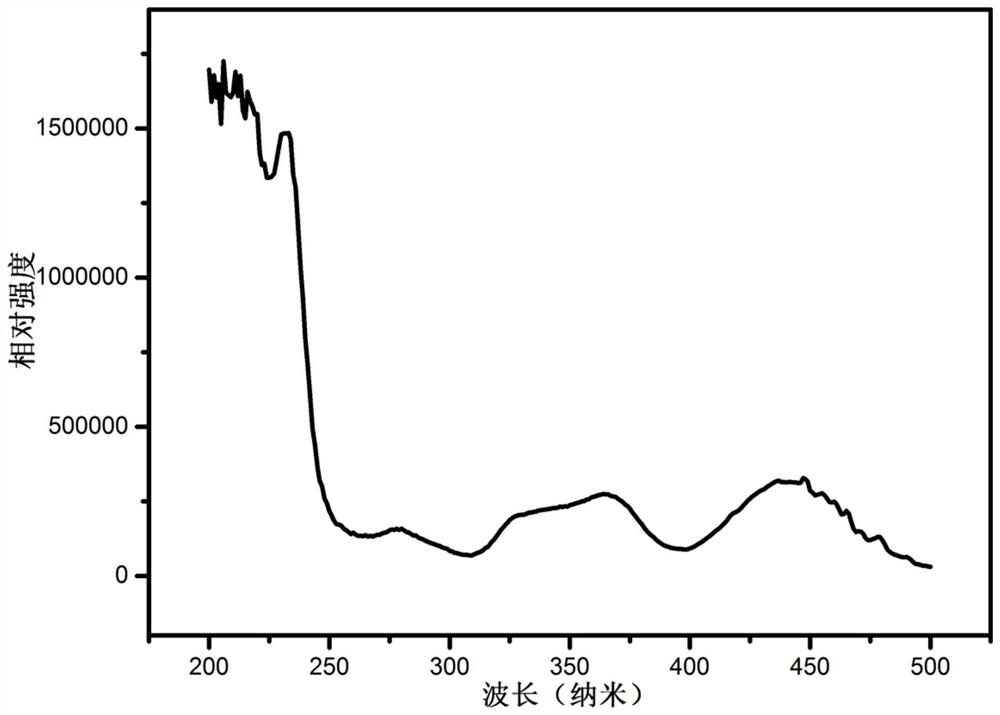

[0034] Example 2: Ca 19.90 al 26 Mg 3 Si 3 o 68 :0.2Ce 3+ ,0.3Tb 3+ ,0.5Li + ;

[0035] Weigh CaCO 3 (Analytical pure) 0.9509g, A1 2 o 3 (analytical pure) 0.6627g, MgO (analytical pure) 0.0604g, SiO 2 (Analytical pure) 0.0902g, Ce 2 (CO 3 ) 3 (99.99%) 0.0230g, Tb 4 o 7 (99.99%) 0.0280g, Li 2 CO 3 (Analytical pure) 0.0092g. Put the above raw materials in an agate mortar, add ethanol with the same volume as the raw materials, and grind for 30 minutes to make the raw materials fully mixed. Transfer the uniformly mixed reactants into a corundum crucible, put it into a high-temperature tube furnace, and heat it under 10% (volume) H at 1350°C 2 , 90% (volume) N 2 Calcined in mixed gas for 2 hours. The reducing atmosphere in the high-temperature tube furnace was lowered to room temperature, and the calcined block sample was ground into powder in an agate mortar to obtain the required phosphor powder with a mass of 1.4114g. The sample glowed green under a 365nm ul...

Embodiment 3

[0036] Example 3: Ca 19.90 al 26 Mg 3 Si 3 o 68 :0.2Ce 3+ ,0.3Tb 3+ ,0.5Li + ;

[0037] Weigh CaO (analytical pure) 0.5325g, A1 2 o 3 (analytical pure) 0.6627g, MgO (analytical pure) 0.0604g, SiO 2 (Analytical pure) 0.0902g, Ce 2 (CO 3 ) 3 (99.99%) 0.0230g, Tb 4 o 7 (99.99%) 0.0280g, Li 2 CO 3 (Analytical pure) 0.0092g. Put the above raw materials in an agate mortar, add ethanol with the same volume as the raw materials, and grind for 30 minutes to make the raw materials fully mixed. Transfer the uniformly mixed reactants into a corundum crucible, put it into a high-temperature tube furnace, and heat it under 10% (volume) H at 1350°C 2 , 90% (volume) N 2 Calcined in mixed gas for 2 hours. In the high-temperature tube furnace, the reducing atmosphere was lowered to room temperature, and the block sample obtained by calcining was ground into powder in an agate mortar to obtain the required phosphor powder with a mass of 1.4110g. The sample glowed green under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com