A kind of flue gas denitrification catalyst and its preparation method and denitrification process

A denitrification catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as scaling and blockage of the heat exchange tube layer, long process, corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

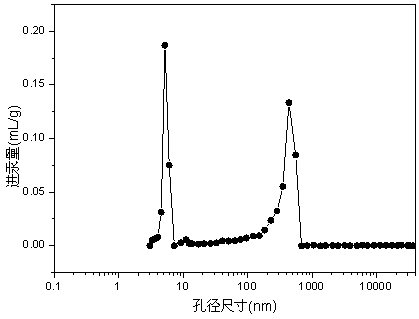

[0047] At room temperature (20°C), mix water, absolute ethanol, aluminum chloride, polyethylene glycol, and formamide evenly, and then add pyridine. The contents of each component of the mixture are by weight: water 23%, ethanol 22% , aluminum chloride 20%, polyethylene glycol (viscosity average molecular weight 1 million) 0.3%, formamide 1%, pyridine 33.7%. After mixing evenly, add 0.5mol / L copper nitrate trihydrate and mix evenly. The resulting mixture is added dropwise into an oil column at 20~50°C to form microspheres, aged at 45°C for 48 hours, and then mixed with ethanol and water Soak the aged mixture for 48 hours. After soaking and removing the liquid phase, dry it at 40°C until the product no longer loses weight significantly. Then calcined at 600° C. for 6 hours, and then cooled to room temperature to obtain catalyst A. The content of CuO is 10wt%, the total porosity is 80%, the pores have a double pore distribution, and the macropores are evenly distributed, the av...

Embodiment 2

[0049] At room temperature (20°C), mix water, absolute ethanol, aluminum chloride, polyethylene glycol, and formamide evenly, and then add pyridine. The contents of each component of the mixture are by weight: water 31%, ethanol 29% , aluminum chloride 16%, polyethylene glycol (viscosity average molecular weight 2 million) 0.5%, formamide 3.5%, pyridine 20%. After mixing evenly, add 0.8mol / L copper nitrate trihydrate and 0.5mol / L ammonium metavanadate solution and mix evenly. The resulting mixture is added dropwise into an oil column at 20~50°C to form microspheres, and aged at 60°C After 24 hours, soak the aged mixture with ethanol for 48 hours. After soaking and removing the liquid phase, dry it at 50° C. until the product no longer loses weight significantly. Then it was calcined at 750° C. for 5 hours, and then cooled to room temperature to obtain catalyst B. CuO content is 15wt%, V 2 o 5 The content is 5%, the total porosity is 75%, the pores have a double pore distrib...

Embodiment 3

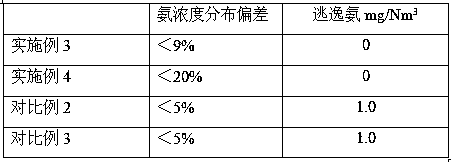

[0055] The catalyst adopts A.

[0056] FCC regeneration flue gas flow rate is 150,000 Nm 3 / h, temperature is 650°C, pressure is 10kPa, NOx concentration is 600mg / Nm 3 , SO 2 The concentration is 1000mg / Nm 3 , SO 3 The concentration is 20mg / Nm 3 , the dust content is 200mg / Nm 3 . NOx emission standard is 200 mg / Nm 3 .

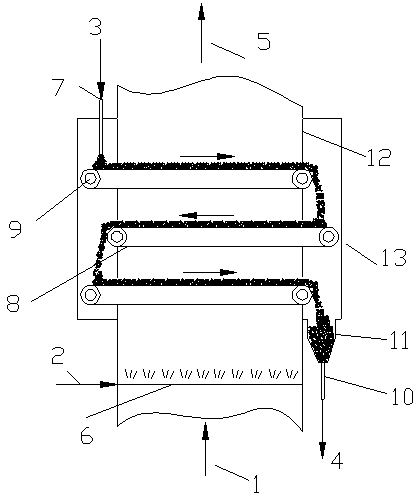

[0057] First, the FCC regenerated flue gas passes through the boiler to obtain heat, and the temperature is lowered from 650°C to the SCR denitrification reaction temperature of 400°C; the flow rate of the mixed gas containing ammonia provided by the raw material supply area is 1120 Nm 3 / h, where the ammonia gas concentration is 4v%, the size of the inner sealed chamber of the reactor is 8m long × 6m wide × 8m high; the reaction time is 0.5s, and 3 layers of conveyor belts are set, and the height of the catalyst bed on each conveyor belt is 300mm. The size of the conveyor belt is 9m long × 5.8m wide. The stainless steel mesh conveyor belt is selected....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com