Method of hole sealing and modification on cold spraying coating on surface of light metal

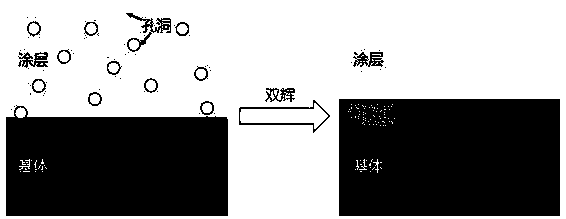

A cold spraying, light metal technology, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problems of insufficient bonding strength, many holes, etc., achieve outstanding engineering value, increase the density of the coating, improve The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Pore sealing modification of cold sprayed pure titanium coating on the surface of 2024 aluminum alloy

[0025] (1) Sample pretreatment. The surface of the 2024 aluminum alloy surface was cold sprayed with pure titanium coating and cleaned with alcohol and dried.

[0026] (2) Put it into the double-glow diafiltration furnace. Place the pure titanium infiltration source and the 2024 aluminum alloy surface cold sprayed pure titanium coating workpiece, and adjust the pole spacing to 40mm.

[0027] (3) vacuuming. Close the air inlet, turn on the vacuum pump, and pump the air pressure in the furnace to 10 -1 Below Pa, then pass argon to the working pressure of 40Pa.

[0028] (4) Plasma cleaning the sample. Turn on the cooling water, start the power supply, first turn on the power supply of the 2024 aluminum alloy surface cold spray pure titanium coating workpiece, apply 500V voltage, and use the plasma beam generated by glow discharge to cold spray the pure titanium co...

Embodiment 2

[0034] Pore sealing modification of cold sprayed pure copper coating on the surface of 2024 aluminum alloy

[0035] (1) Sample pretreatment. Clean the surface of the sample with alcohol and dry it, if necessary, polish it first and then clean it.

[0036] (2) Put it into the double-glow diafiltration furnace. Place the infiltration source of pure copper target material, cold spray pure copper coating workpiece on the surface of 2024 aluminum alloy, and adjust the pole spacing to 30mm.

[0037] (3) vacuuming. Close the air inlet, turn on the vacuum pump, and pump the air pressure in the furnace to 10 -1 Below Pa, then pass argon to the working pressure of 30Pa.

[0038] (4) Plasma cleaning the sample. Turn on the cooling water, start the power supply, first turn on the power supply of the 2024 aluminum alloy surface cold spray pure copper coating workpiece, apply 400V voltage, and use the plasma beam generated by glow discharge to cold spray the pure copper coating workp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com