A kind of anti-oxidizing disinfectant corrosion epoxy primer, modified polyester topcoat, color-coated steel plate and color-coated steel plate manufacturing process

A technology of oxidation resistance, color-coated steel plate, applied in polyester coating, epoxy resin coating, metal material coating process, etc. The effect of medium corrosion ability, strong pertinence and good machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

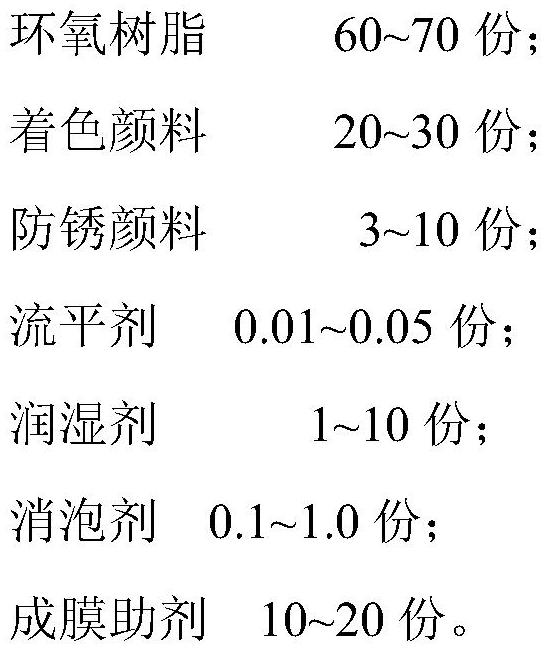

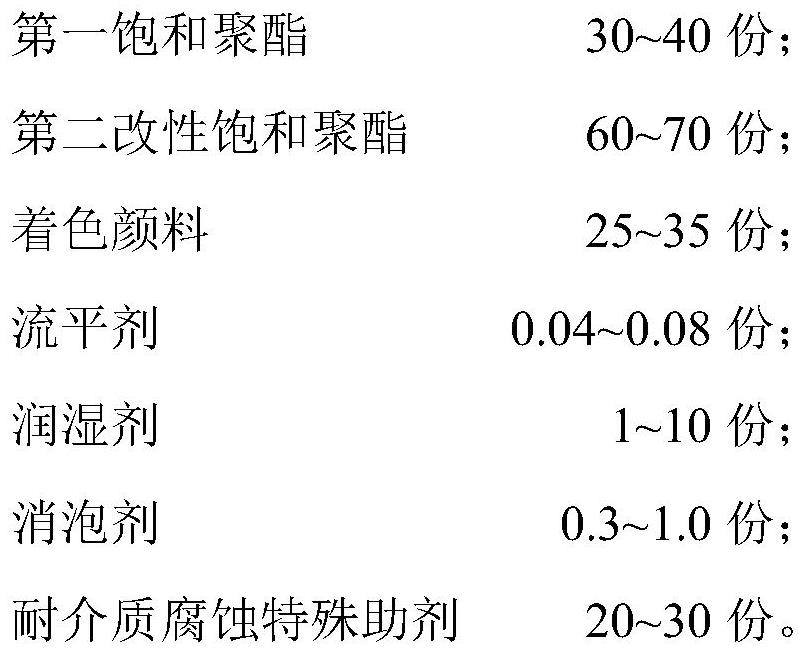

[0070] The dry film composition of a kind of anti-oxidant disinfectant corrosion epoxy primer, polyester topcoat, epoxy back paint of each embodiment is as shown in table 2

[0071] The formula of table 2 embodiment and comparative example

[0072]

[0073]

[0074] Select the coating weight as 120g / m 2 (Double-sided) hot-dip galvanized steel plate as color pre-coated substrate 1, the process of preparing color-coated steel plate: galvanized plate-degreasing-cleaning-passivation-front and back primer coating-curing-front topcoat Coating—solidification—cooling—inspection—coiling, to make the color-coated steel sheets of Examples 1 to 3 and Comparative Examples, wherein the film thickness of the front primer is controlled at 5 to 7 μm, and the film thickness of the front top coat is controlled at 15 μm. ~17μm, and the film thickness of the back paint is controlled at 5~12μm.

[0075] Specifically, the steps in the manufacturing process of the color-coated steel plate cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com