A kind of wall color decorative mortar and preparation method thereof

A technology for colored veneer mortar and wall, applied in the field of building materials, can solve the problems of waste of resources, occupation of cultivated land, pollution of the environment, etc., and achieve the effect of low cost and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

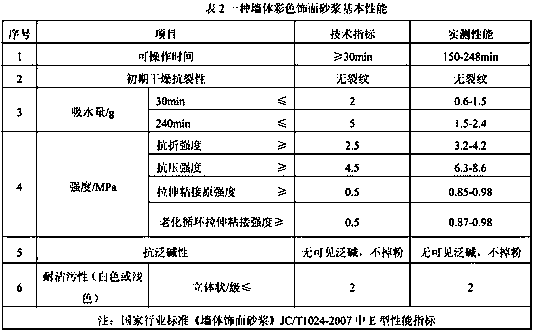

Examples

Embodiment 1

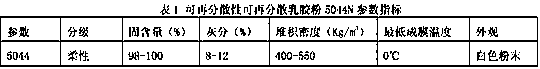

[0038] A kind of wall color decorative mortar, which comprises the following raw materials prepared in parts by weight: 250 parts of recycled gypsum, 500 parts of quartz sand, 100 parts of heavy calcium carbonate, 5 parts of redispersible latex powder, cellulose ether 0.2 parts, 4 parts of inorganic pigments, 2 parts of waterproofing agents, 1.2 parts of retarders and 0.5 parts of water reducers; the redispersible latex powder is vinyl acetate / ethylene copolymer powder; the cellulose ether is hydroxyl Propyl methyl cellulose ether; the waterproofing agent is a modified silicone waterproofing agent; the water-reducing agent is a low-alkali naphthalene-based water-reducing agent; the retarder is sodium tripolyphosphate powder. The fineness of the regenerated gypsum is 1100m 2 / kg, the initial setting time is 7min, and the final setting time is 12min. The quartz sand adopts the following particle size and gradation: 20-40 mesh: 35%, 40-70 mesh: 55%, 70-140 mesh: 10%. Described ...

Embodiment 2

[0041] A colored decorative mortar for walls, which is prepared by the following raw materials in parts by weight: 350 parts of recycled gypsum, 600 parts of quartz sand, 100 parts of heavy calcium carbonate, 10 parts of redispersible latex powder, cellulose ether 0.4 parts, 10 parts of inorganic pigments, 4 parts of waterproofing agent, 1.8 parts of retarder and 1 part of water reducer; the described redispersible latex powder is vinyl acetate / ethylene copolymer powder; the cellulose ether is hydroxyl Propyl methyl cellulose ether; the waterproofing agent is a modified silicone waterproofing agent; the water-reducing agent is a low-alkali naphthalene-based water-reducing agent; the retarder is sodium tripolyphosphate powder. The fineness of the regenerated gypsum is 1100m 2 / kg, the initial setting time is 7min, and the final setting time is 12min. The quartz sand adopts the following particle size and gradation: 20-40 mesh: 45%, 40-70 mesh: 45%, 70-140 mesh: 10%. Described...

Embodiment 3

[0044] A kind of wall color decorative mortar, the mortar comprises the following raw materials prepared according to weight parts: 300 parts of recycled gypsum, 550 parts of quartz sand, 100 parts of heavy calcium carbonate, 7.5 parts of redispersible latex powder, cellulose ether 0.3 parts, 7 parts of inorganic pigments, 3 parts of waterproofing agents, 1.5 parts of retarders and 0.75 parts of water reducers; the redispersible latex powder is vinyl acetate / ethylene copolymer powder; the cellulose ether is hydroxyl Propyl methyl cellulose ether; the waterproofing agent is a modified silicone waterproofing agent; the water-reducing agent is a low-alkali naphthalene-based water-reducing agent; the retarder is sodium tripolyphosphate powder. The fineness of the regenerated gypsum is 1100m 2 / kg, the initial setting time is 7min, and the final setting time is 12min. The quartz sand adopts the following particle size and gradation: 20-40 mesh: 40%, 40-70 mesh: 50%, 70-140 mesh: 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com