Method for producing zinc based on choline chloride-malonic acid low eutectic system

A technology of choline chloride and malonic acid, which is applied to the improvement of process efficiency, photography process, electrodes and other directions, can solve problems such as low viscosity of molten salt of zinc coating, and achieves simple and easy operation, fast electrodeposition rate, Simple effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) The molar ratio of choline chloride, malonic acid and zinc oxide in the electrolyte is 4:4:1. Mix choline chloride, malonic acid and zinc oxide in a certain proportion and then heat to 90°C. Keep warm until stirring produces a clear viscous liquid. Then add 0.1mol / L ethylenediamine.

[0025] 2) Use the zinc sheet as a soluble anode, and the copper block as a cathode, put it into the above mixed liquid heated to 90°C for 60 minutes of double-anode constant current electrodeposition, where the distance between the anode and the cathode is 2cm, and the current density is 25mA / cm 2 .

[0026] 3) After electrodeposition, the sample was taken out and cleaned ultrasonically with absolute ethanol and deionized water, and finally blown with a hair dryer at low temperature.

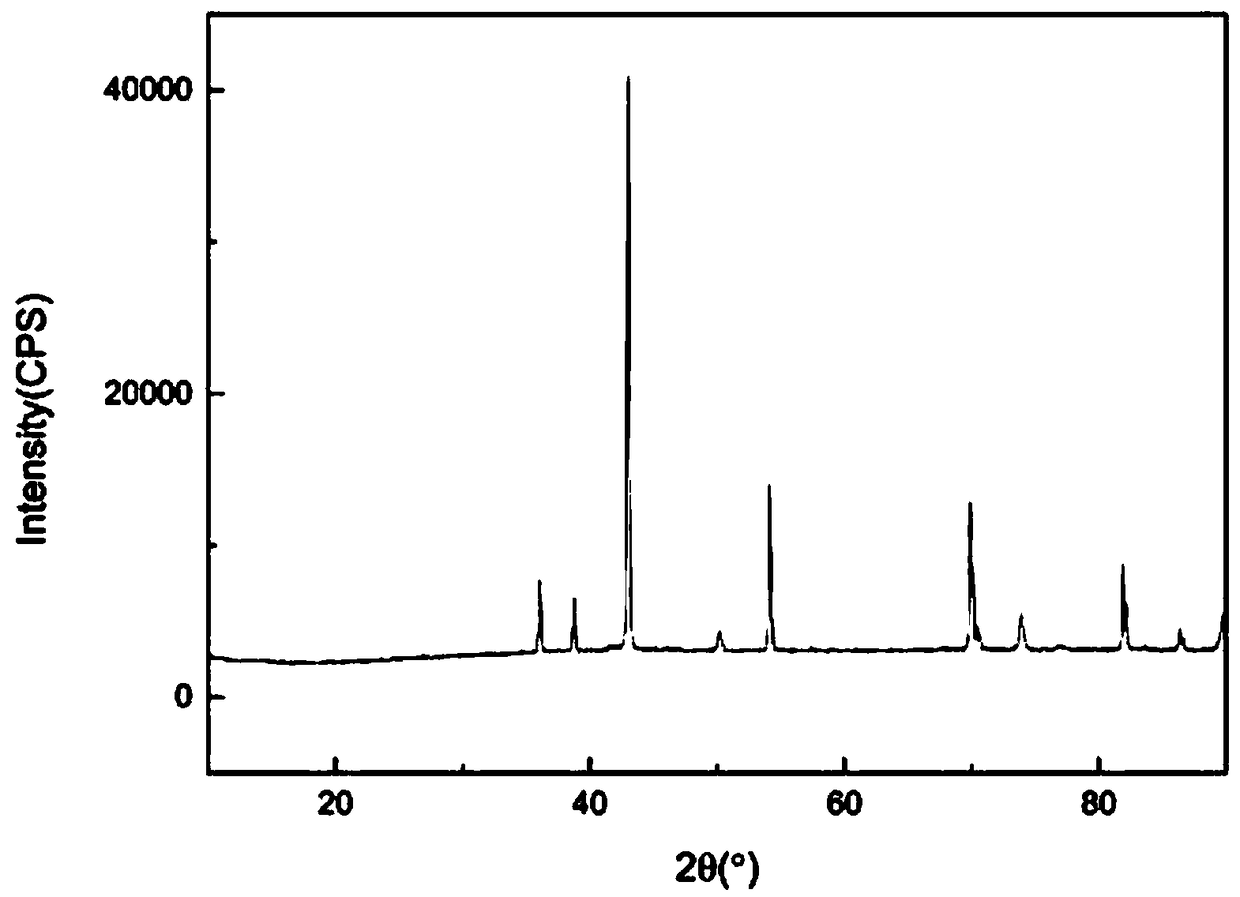

[0027] The XRD figure of gained coating sees figure 2 , it can be found that the coating on the copper substrate is a zinc coating.

Embodiment 2

[0029] 1) The molar ratio of choline chloride, malonic acid and zinc oxide in the electrolyte is 4:4:1. Mix choline chloride, malonic acid and zinc oxide in a certain proportion and then heat to 90°C. Keep warm until stirring produces a clear viscous liquid. Then add 0.1mol / L ethylenediamine.

[0030] 2) Use the zinc sheet as a soluble anode, and the copper block as a cathode, and put it into the above mixed liquid heated to 90°C for 60 minutes of double-anode constant current electrodeposition, wherein the distance between the anode and the cathode is 2cm, and the current density is 20mA / cm 2 .

[0031] 3) After electrodeposition, the sample was taken out and cleaned ultrasonically with absolute ethanol and deionized water, and finally blown with a hair dryer at low temperature.

[0032] The EDS energy spectrum of gained coating sees figure 2 , it can be found that the coating on the copper substrate is a zinc coating.

Embodiment 3

[0034] 1) The molar ratio of choline chloride, malonic acid and zinc oxide in the electrolyte is 4:4:1. Mix choline chloride, malonic acid and zinc oxide in a certain proportion and then heat to 90°C. Keep warm until stirring produces a clear viscous liquid. Then add 0.1mol / L ethylenediamine.

[0035] 2) Use the zinc sheet as a soluble anode, and the copper block as a cathode, and put it into the above mixed liquid heated to 90°C for 60 minutes of double-anode constant current electrodeposition, where the distance between the anode and the cathode is 2cm, and the current density is 15mA / cm 2 .

[0036] 3) After electrodeposition, the sample was taken out and cleaned ultrasonically with absolute ethanol and deionized water, and finally blown with a hair dryer at low temperature.

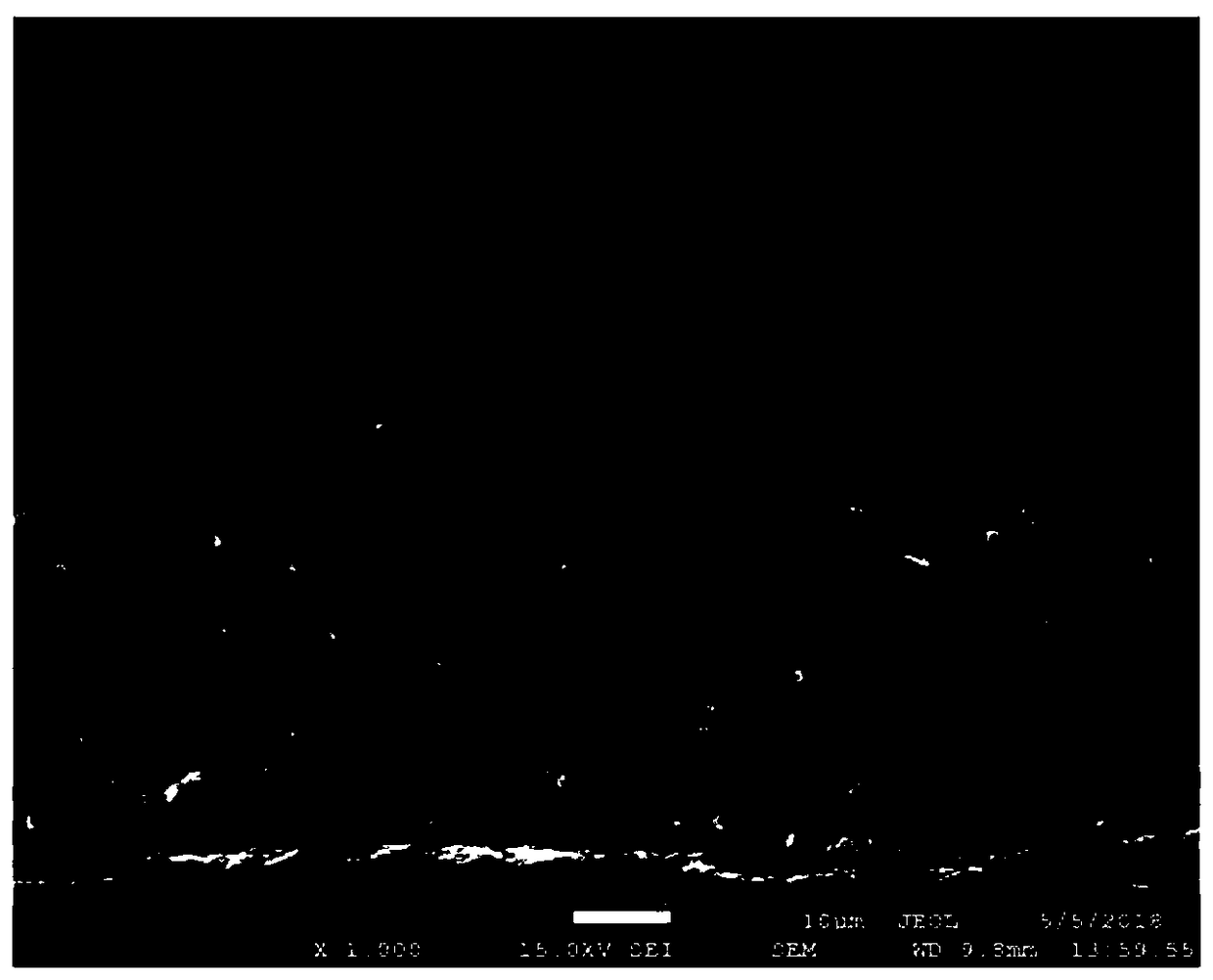

[0037] The surface energy spectrum analysis figure of gained coating sees image 3 , it can be found that the coating on the copper substrate is closely combined with the substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com