Felt panels with thermal insulation and sound absorption

A heat insulation and sound absorption technology, applied in construction, building components, fire protection, etc., can solve the problems of poor high temperature resistance, unsatisfactory noise reduction effect, etc., achieve excellent fire resistance performance, good non-combustibility and chemical resistance, and improve sound absorption performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

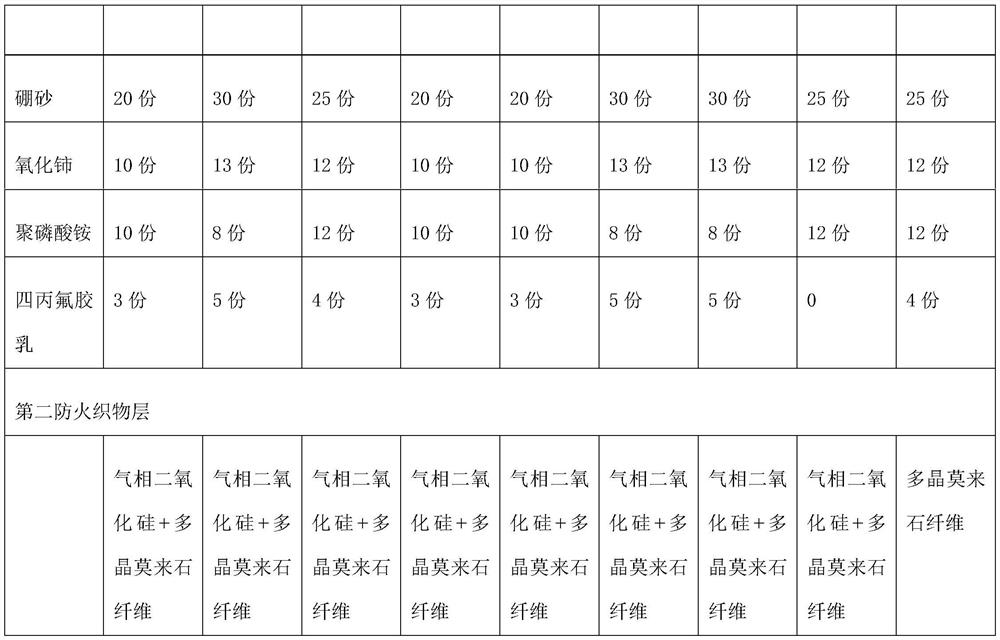

[0030] This case provides a heat-insulating and sound-absorbing felt board, wherein the heat-insulating and sound-absorbing felt board includes a first fire-proof fabric layer, a heat-insulating and sound-absorbing layer and a second fire-proof fabric layer stacked sequentially from top to bottom;

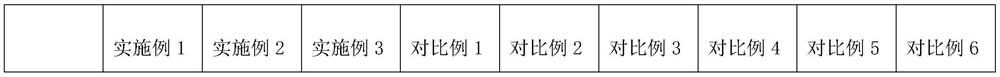

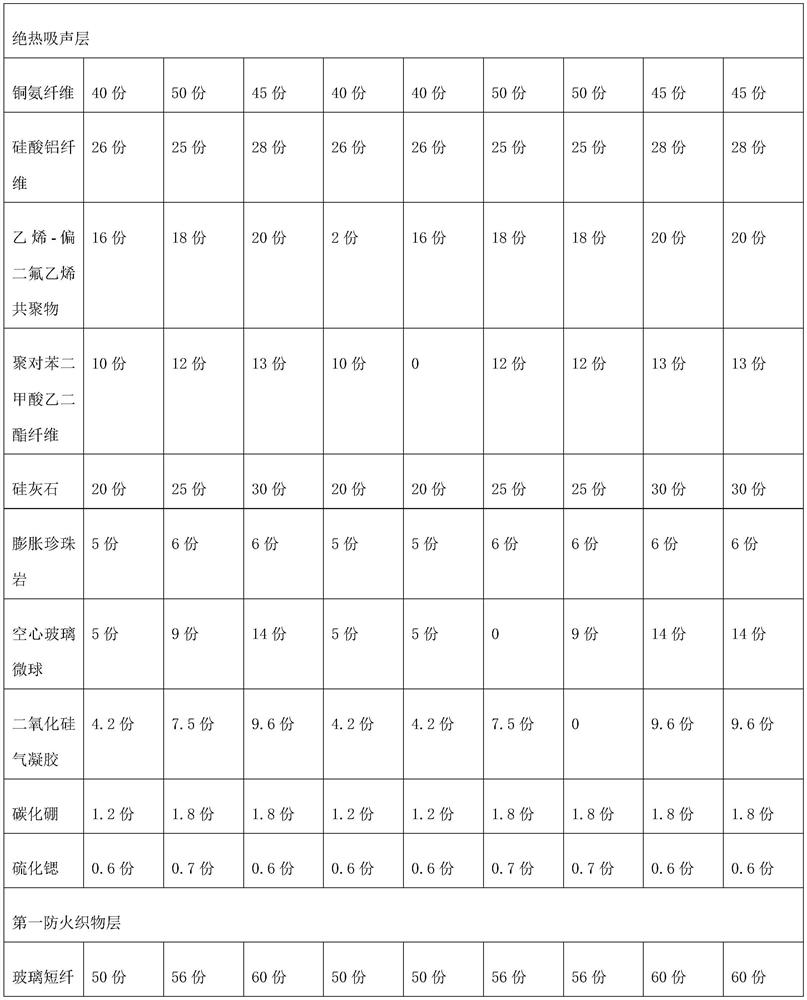

[0031] Wherein, the heat-insulating and sound-absorbing layer includes the following materials in parts by weight:

[0032] Cupro ammonia fiber 40~60 parts;

[0033] Aluminum silicate fiber 24~30 parts;

[0034] Ethylene-vinylidene fluoride copolymer 15~20 parts;

[0035] 8~14 parts of polyethylene terephthalate fiber;

[0036] Wollastonite 20~40 parts;

[0037] 10~20 parts of sound absorbing agent;

[0038] 6~12 parts of heat preservation agent.

[0039] As the main body of the heat-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com