Preparation method of conjugate polyvinyl alcohol modified nano molybdenum disulfide

A polyvinyl alcohol, molybdenum disulfide technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of catalysis efficiency to be improved, acute poisoning, high cost, etc., and achieve good catalysis Reduced effect, good visible light absorption, improved photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

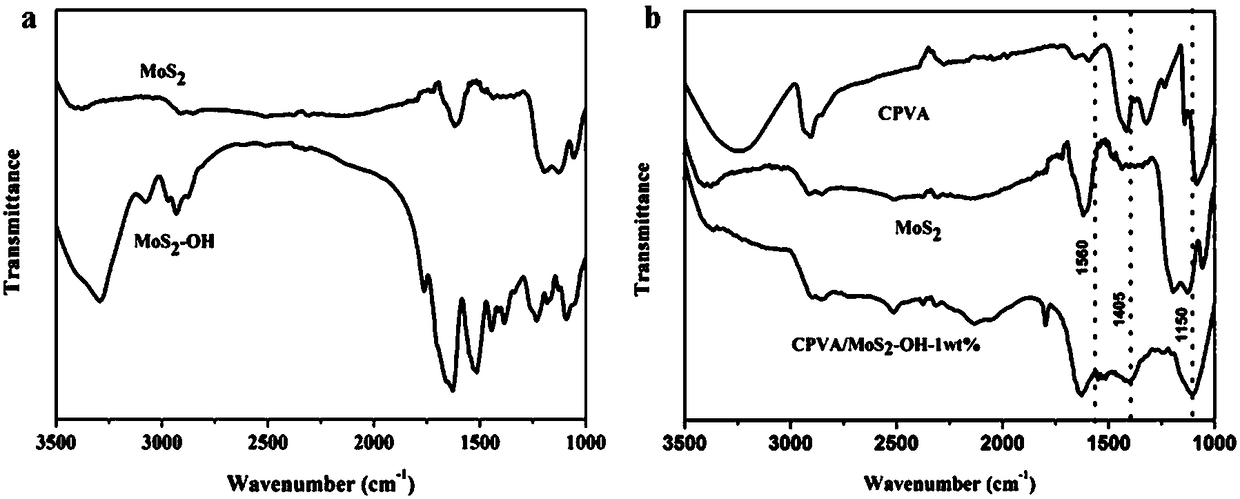

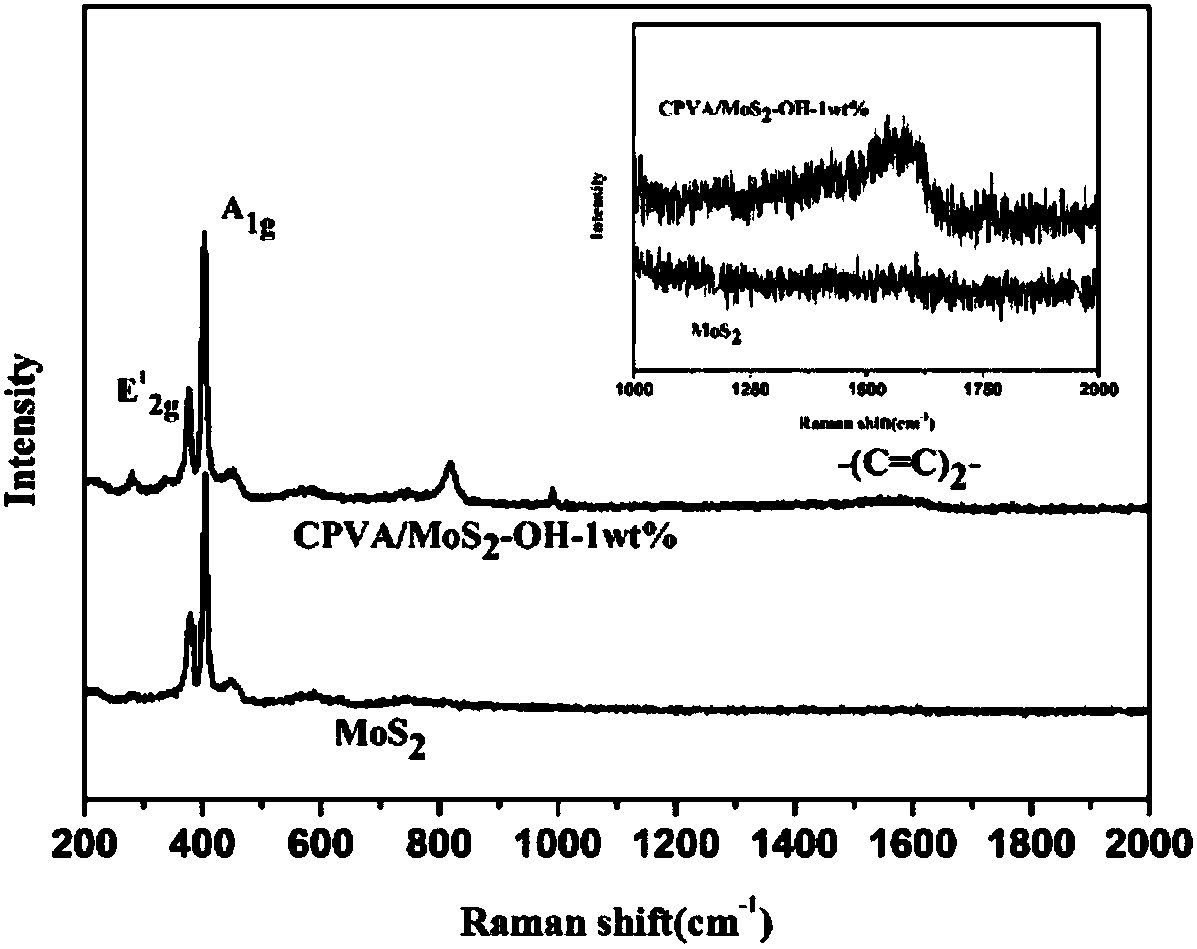

[0029] This embodiment prepares the conjugated polyvinyl alcohol / hydroxylated molybdenum disulfide complex according to the following steps:

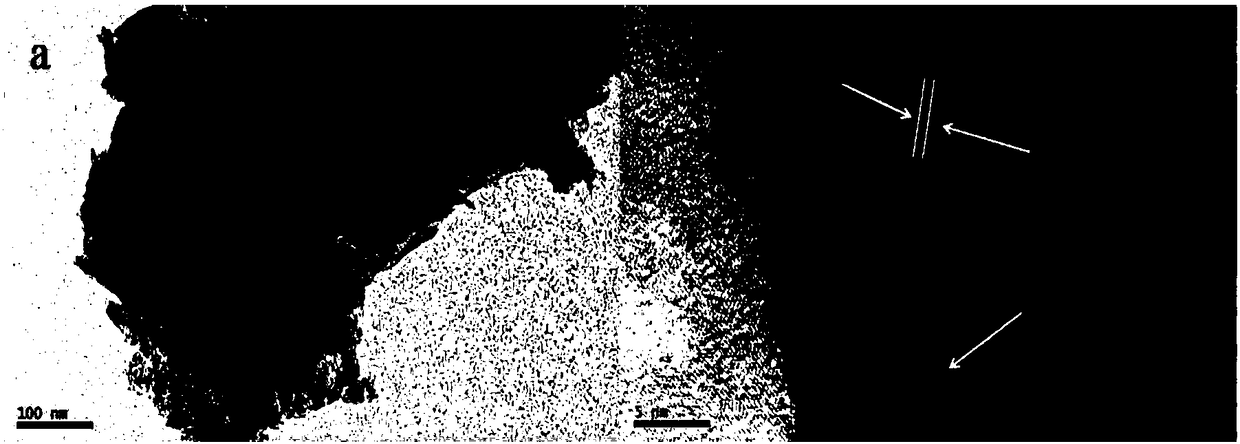

[0030] 1. Preparation of lamellar molybdenum disulfide

[0031] Add 1g of molybdenum disulfide powder into a three-necked flask, then add 10mL of n-butyllithium, and stir for three days under a nitrogen atmosphere. The obtained product was dried in a constant temperature drying oven at 60°C for 4 hours, and the dried powder was dissolved in 250 mL of deionized water, ultrasonically dispersed for 12 hours, and then freeze-dried at -50°C for 24 hours to obtain lamellar molybdenum disulfide.

[0032] 2. Preparation of hydroxylated molybdenum disulfide

[0033] Disperse 0.7g lamellar molybdenum disulfide in 200mL deionized water, add 2mL mercaptoethanol, ultrasonicate for 48 hours, then freeze-dry at -50°C for 24 hours, wash and dry the freeze-dried product with ethanol to obtain hydroxylated disulfide molybdenum.

[0034] 3. Preparation...

Embodiment 2

[0037] In this example, the conjugated polyvinyl alcohol / hydroxylated molybdenum disulfide composite is prepared according to the same method as in Example 1, the only difference being that the mass ratio of the polyvinyl alcohol (0.0005 g) to the hydroxylated molybdenum disulfide in step 3 is 0.5%, the resulting conjugated polyvinyl alcohol / hydroxylated molybdenum disulfide complex is denoted as CPVA / MoS 2 -OH-0.5 wt%.

Embodiment 3

[0039] In this example, the conjugated polyvinyl alcohol / hydroxylated molybdenum disulfide composite was prepared according to the same method as in Example 1, the only difference being that the mass ratio of the polyvinyl alcohol (0.0010 g) to the hydroxylated molybdenum disulfide in step 3 was 1.0%, the resulting conjugated polyvinyl alcohol / hydroxylated molybdenum disulfide complex is denoted as CPVA / MoS 2 -OH-1wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com