Recombinant bacillus subtilis and application

A technology of Bacillus subtilis and Bacillus subtilis is applied in the field of recombinant microorganism genetic engineering and can solve the problems of large carbon flux and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] KHG / KDPG aldolase gene kdgA

[0023] According to the upstream and downstream sequences of the pyruvate kinase encoding gene pckA of Bacillus subtilis (Bacillus subtilis 168 purchased from the American Type Microorganism Collection, ATCC NO.27370) published on NCBI, and the sequence of the bleomycin resistance gene, the sequence was constructed Knockout box as shown in SEQ ID NO.1.

[0024] The specific construction process is as follows: the starting strain is based on B. subtilis 168, the genotype is modified as follows: ΔnagPΔgamPΔgamAΔnagAΔnagBΔldhΔptaΔglckΔpckA::lox72, and the promoter P xylA ,P 43 Control the recombinant expression of glmS and GNA1. The KHG / KDPG aldolase gene kdgA of the recombinant Bacillus subtilis BSGNK-PxylA-glmS-P43-GNA1 is knocked out by constructing a KHG / KDPG aldolase coding gene knockout frame, and the knockout frame is knocked out by homologous recombination. The bleomycin resistance gene zeo replaced the KHG / KDPG aldolase gene kdgA i...

Embodiment 2

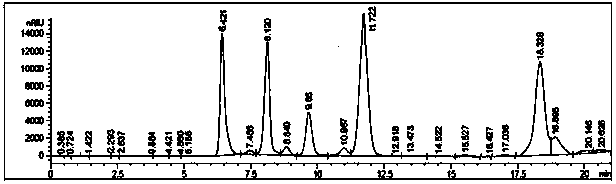

[0028] Determination method of acetylglucosamine:

[0029] High performance liquid chromatography (HPLC) detection method: Agilent 1200, RID detector, NH Column (250 * 4.6mm, 5 μ m), mobile phase: 70% acetonitrile, flow rate 0.75mL / min, column temperature 30 ℃, injection volume is 10 μL.

[0030] Seed medium (g / L): tryptone 10, yeast powder 5, NaCl10.

[0031] The fermentation medium is a compound medium; the compound medium is calculated in g / L, containing: glucose 60, peptone 6, yeast powder 12, (NH 4 ) SO 4 6,K 2 HPO 4 ·3H 2 O 12.5, KH 2 PO 4 2.5, CaCO 3 5. Trace element 10ml / L; trace element solution contains in g / L: MnSO 4 ·5H 2 O 1.0, C O cl 2 ·6H 2 O 0.4, NaMoO 4 2H 2 O 0.2, ZnSO 4 ·7H 2 O 0.2, AlCl 3 ·6H 2 O 0.1, CuCl 2 ·H 2 O 0.1, H 3 BO 4 0.05 with 5M HCl.

[0032]Culture conditions: Transfer the seeds cultivated at 37°C and 220rpm for 12h to the fermentation medium with an inoculation amount of 5%, add the inducer xylose 5g / L after 2h inocula...

Embodiment 3

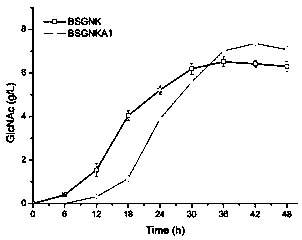

[0034] Fermentation of Acetyl Glucosamine

[0035] The seeds cultivated at 37° C. and 220 rpm for 12 hours were transferred to the fermentation medium at an inoculum size of 5%, and cultivated at 30-37° C. and 200-220 rpm for 48-52 hours. After 36 hours of fermentation, the content of acetylglucosamine in the fermentation supernatant reached 11.13g / L, which was 67.8% higher than that of the strain before the knockout (see attached Figure 1-2 Shown), realized the improvement of the extracellular production of acetylglucosamine in the recombinant Bacillus subtilis.

[0036] Table 1 Cell growth and acetylglucosamine synthesis of BSGNK and control bacteria BSGNKA1

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com