4H-SiC semiconductor neutron detector applied to prompt fission neutron uranium mine logging

A neutron detector and fission neutron technology, applied in the field of nuclear radiation detection, can solve the problems of not fully exploiting the properties of 4H-SiC materials, not fully utilizing the growth process and device preparation technology, etc., to optimize in-situ etching parameters , Improve charge collection efficiency, remove surface damage and stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

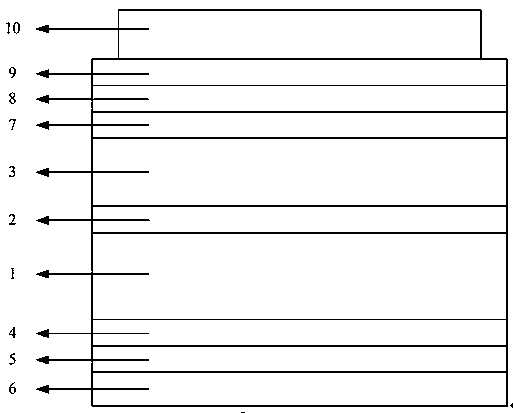

Image

Examples

Embodiment 1

[0026] A preparation method for a 4H-SiC neutron detector applied to prompt fission neutron uranium ore logging mainly includes the following steps:

[0027] (1) Choose a 6-inch n + type 4H-SiC substrate with a thickness of 380 μm and an N doping concentration of 2×1018 cm -3 , the crystal orientation deviates from {0001}0°( direction), the dislocation density is lower than 3×10 2 cm -2 , and good uniformity, double-sided polishing.

[0028] (2) The cleaning sequence is: clean the substrate with deionized water (DIW) supplemented by ultrasonic cleaning to remove impurity particles on the surface; clean the substrate with a 1:1 mixture of concentrated sulfuric acid and hydrogen peroxide for 15 minutes, and then clean it with deionized water ; soak the substrate with 10% HF solution for 10 minutes, and then clean it with deionized water; in No. 1 cleaning solution (NH 4 OH: H 2 o 2 : DIW three ratios are 3:3:10), then soaked in buffered hydrofluoric acid with a concentra...

Embodiment 2

[0036] A preparation method for a 4H-SiC neutron detector applied to prompt fission neutron uranium ore logging mainly includes the following steps:

[0037] (1) Choose a 6-inch n + type 4H-SiC substrate with a thickness of 380 μm and a N doping concentration of 5×10 18 cm -3 , the crystal orientation deviates from {0001}0°( direction), the dislocation density is lower than 3×10 2 cm -2 , and good uniformity, double-sided polishing.

[0038] (2) The cleaning sequence is: clean the substrate with deionized water (DIW) supplemented by ultrasonic cleaning to remove impurity particles on the surface; clean the substrate with a 1:1 mixture of concentrated sulfuric acid and hydrogen peroxide for 15 minutes, and then clean it with deionized water ; soak the substrate with 10% HF solution for 10 minutes, and then clean it with deionized water; in No. 1 cleaning solution (NH 4 OH: H 2 o 2 : DIW three ratios are 3:3:10), then soaked in buffered hydrofluoric acid with a concentr...

Embodiment 3

[0046] A preparation method for a 4H-SiC neutron detector applied to prompt fission neutron uranium ore logging mainly includes the following steps:

[0047] (1) Choose a 6-inch n + type 4H-SiC substrate with a thickness of 350 μm and an N doping concentration of 1×10 18 cm -3 , the crystal orientation deviates from {0001}0°( direction), the dislocation density is lower than 3×10 2 cm -2 , and good uniformity, double-sided polishing.

[0048] (2) The cleaning sequence is: clean the substrate with deionized water (DIW) supplemented by ultrasonic cleaning to remove impurity particles on the surface; clean the substrate with a 1:1 mixture of concentrated sulfuric acid and hydrogen peroxide for 15 minutes, and then clean it with deionized water ; soak the substrate with 10% HF solution for 10 minutes, and then clean it with deionized water; in No. 1 cleaning solution (NH 4 OH: H 2 o 2 : DIW three ratios are 3:3:10), then soaked in buffered hydrofluoric acid with a concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Contact resistivity | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com