3D direct writing zirconium oxide ceramic ink

A technology of zirconia ceramics and zirconia particles, applied in the field of 3D printing materials, can solve the problems of low forming precision, low forming strength and high cost, and achieve the effects of good elastic properties and strength, wide application range and good rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Zirconia particles (preferably particle size D 50 =0.8um), deionized water, cellulose, polyvinyl acid, and ammonium chloride are mixed to form a slurry; the solid phase content of zirconia is 44%, the cellulose content is 0.002g / ml, and polyvinyl acid is a dry powder of zirconia particles content of 0.6%, and the amount of ammonium chloride is 0.06% of the ink mass. After mixing the above materials in proportion, they are placed on a ball mill and milled at a speed of 90rmp for 12 hours to obtain zirconia ceramic ink. The zirconia ceramic ink has very good Shear thinning, which in 10s -1 The viscosity at the shear rate is 2Pa·s, and it has very good viscoelasticity, and its elastic modulus at 1pa is as high as 10 3 Pa, has good shape retention, can pass through the needle nozzle blockage smoothly and maintain a three-dimensional shape, then put the ink into the spray barrel of the 3D direct writing device, the nozzle diameter is 100um, set the program of the 3D direct ...

Embodiment 2

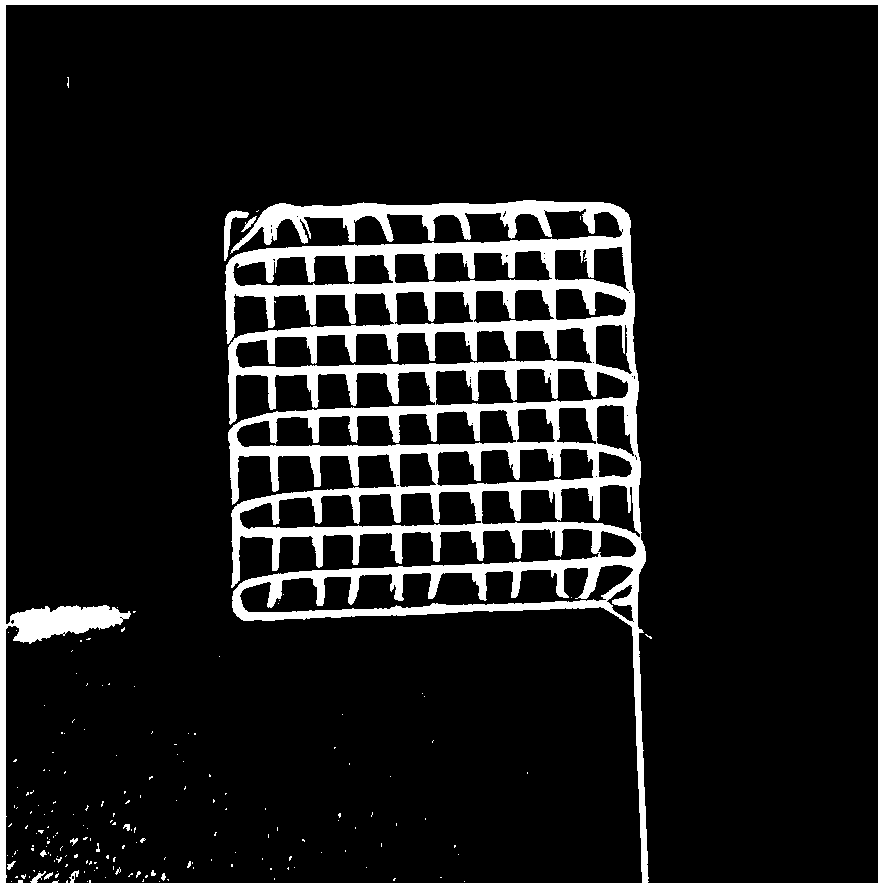

[0049] 1 μm zirconia particles, deionized water, zinc acetate, hydantoin epoxy resin, ammonium polyacrylate; in the slurry: zirconia solid phase content ranges from 56vol%, hydantoin epoxy resin with a content of 15wt%, ammonium polyacrylate The content of dry powder of zirconia particles is 0.8%, and the dosage of zinc acetate is 0.05% of the ink mass. Mix the above materials in proportion and put them on a ball mill at a speed of 100-140rmp for 12-24h, remove them, and ultrasonically oscillate for 1-12h Then get 3D direct writing zirconia ceramic ink. its in 10s -1 The viscosity at the shear rate is 3Pa·s, and it has very good viscoelasticity, and its elastic modulus at 10pa is as high as 10 3 Pa, has good shape retention, can pass through the nozzle plug smoothly and maintain a three-dimensional shape, (see Figure 5-6 )

[0050] The 3D direct writing zirconia ceramic ink is loaded into the spray barrel of the 3D direct writing device, the nozzle diameter is 2um, the pro...

Embodiment 3

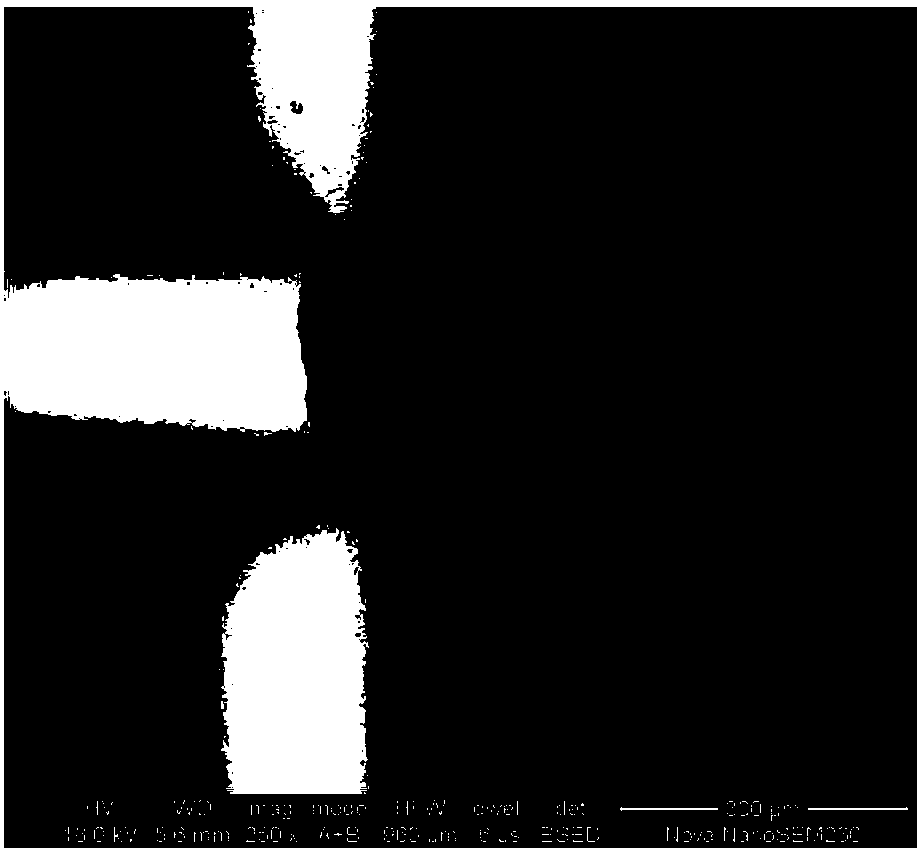

[0052] Mix 0.5 μm zirconia particles, deionized water, gum arabic, sodium polycarboxylate, and sodium chloride evenly, the solid phase content of zirconia is 40vol%, the gum arabic content is 0.08g / ml, sodium polycarboxylate The salt is 1% of the dry powder content of zirconia particles, and the amount of sodium chloride is 0.1% of the ink mass. The above materials are mixed in proportion and placed on a ball mill at a speed of 100-140rmp for 12-24h, removed, and ultrasonically oscillated for 1 After -12h, the 3D direct writing zirconia ceramic ink is obtained. its in 10s -1 The viscosity at the shear rate is 2Pa·s, and has very good viscoelasticity, and its elastic modulus at 0.5pa is as high as 10 3 Pa, has good shape retention, can pass through the nozzle plug smoothly and maintain a three-dimensional shape, (see Figure 7-8 )

[0053] The 3D direct writing zirconia ceramic ink is loaded into the spray barrel of the 3D direct writing device, the nozzle diameter is 10um, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com