Preparation method of smoke-free aluminum alloy polishing solution

A technology of polishing liquid and aluminum alloy, which is applied in the direction of polishing compositions containing abrasives, etc., can solve the problems of workers’ health damage, fast corrosion rate, and impact on the environment, so as to reduce corrosive pitting, enhance oxidation performance, and apply promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

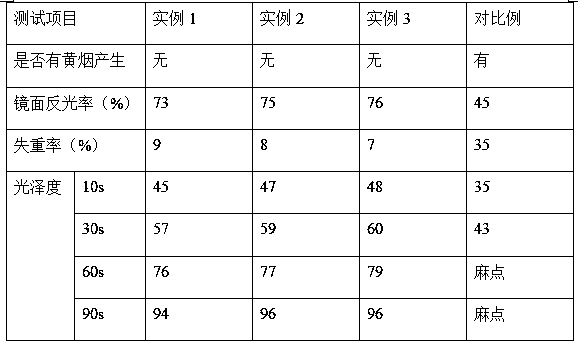

Examples

Embodiment Construction

[0024] Take bauxite and put it in a ball mill to pulverize for 40-45 minutes, pass through a 200-mesh sieve to obtain bauxite powder, mix 40% sodium hydroxide solution and bauxite powder in a mass ratio of 4:1, and mix them in the ball mill Continue wet grinding in the medium to make the causticization coefficient reach 1.65-1.70 to obtain alkalized suspension; put the alkalized suspension under high pressure condition of 2.5-3.0MPa, heat up to 160-180°C, hold heat and hold pressure for 2-3 hours to dissolve Impurities, add 300-400mL deionized water to the alkalized suspension, stir and mix for 30-45 minutes, then let it settle for 3-4 hours, filter and separate to obtain the supernatant, put the supernatant in a crucible, and heat up to 120- Evaporate at 140°C for 3 to 4 hours to obtain dry powder; weigh 60 to 70 mL of aniline and 50 to 55 mL of absolute ethanol, put them into a three-necked flask equipped with a reflux condenser and a stirring device, start the stirrer to sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com