Method for realizing giant negative thermal expansion of wide temperature area in MnCoGe base alloy

A technology with negative thermal expansion and wide temperature range, applied in the direction of nanotechnology, can solve the problem of few MnCoGe-based alloys, and achieve the effect of simple and convenient preparation method, less energy consumption and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

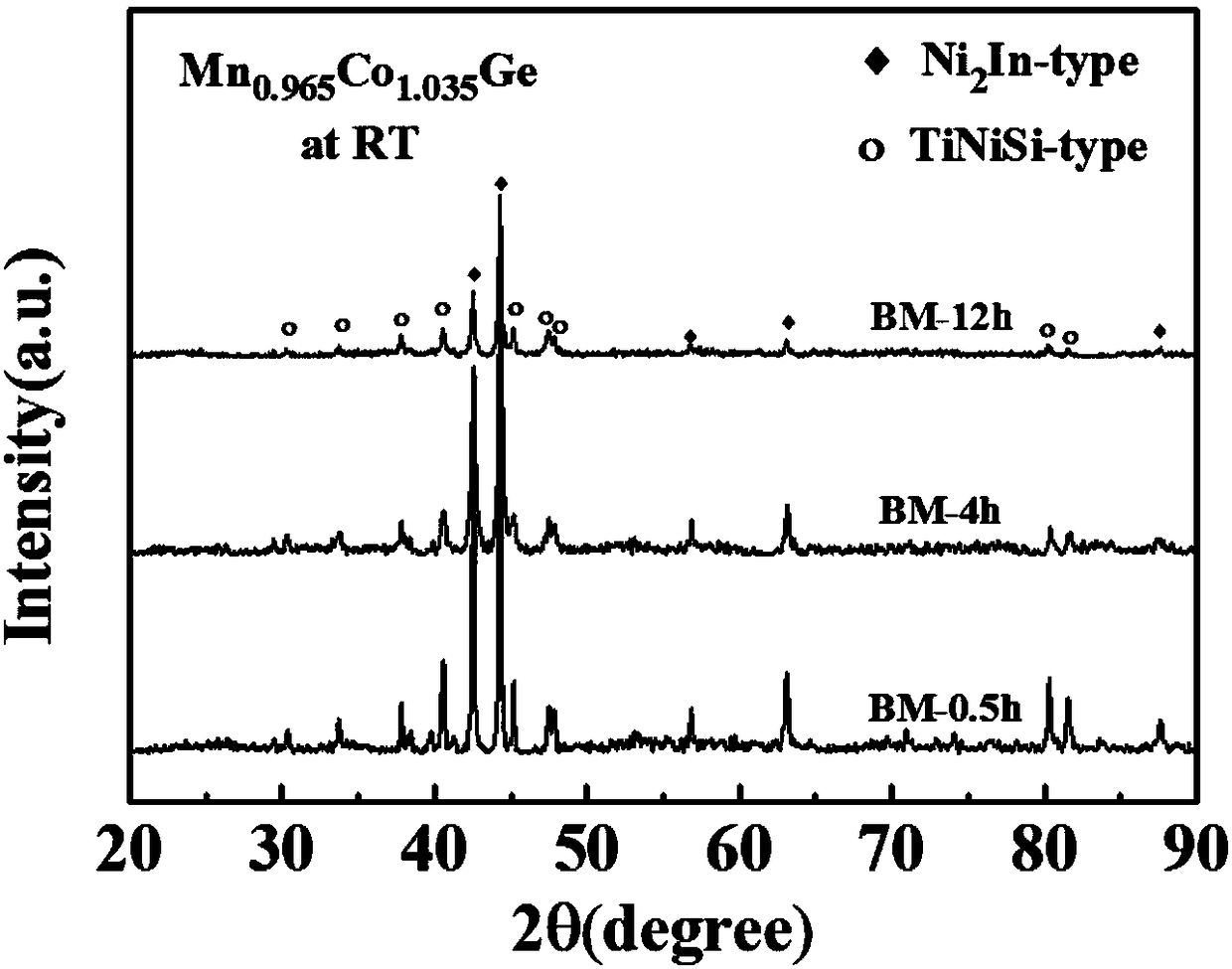

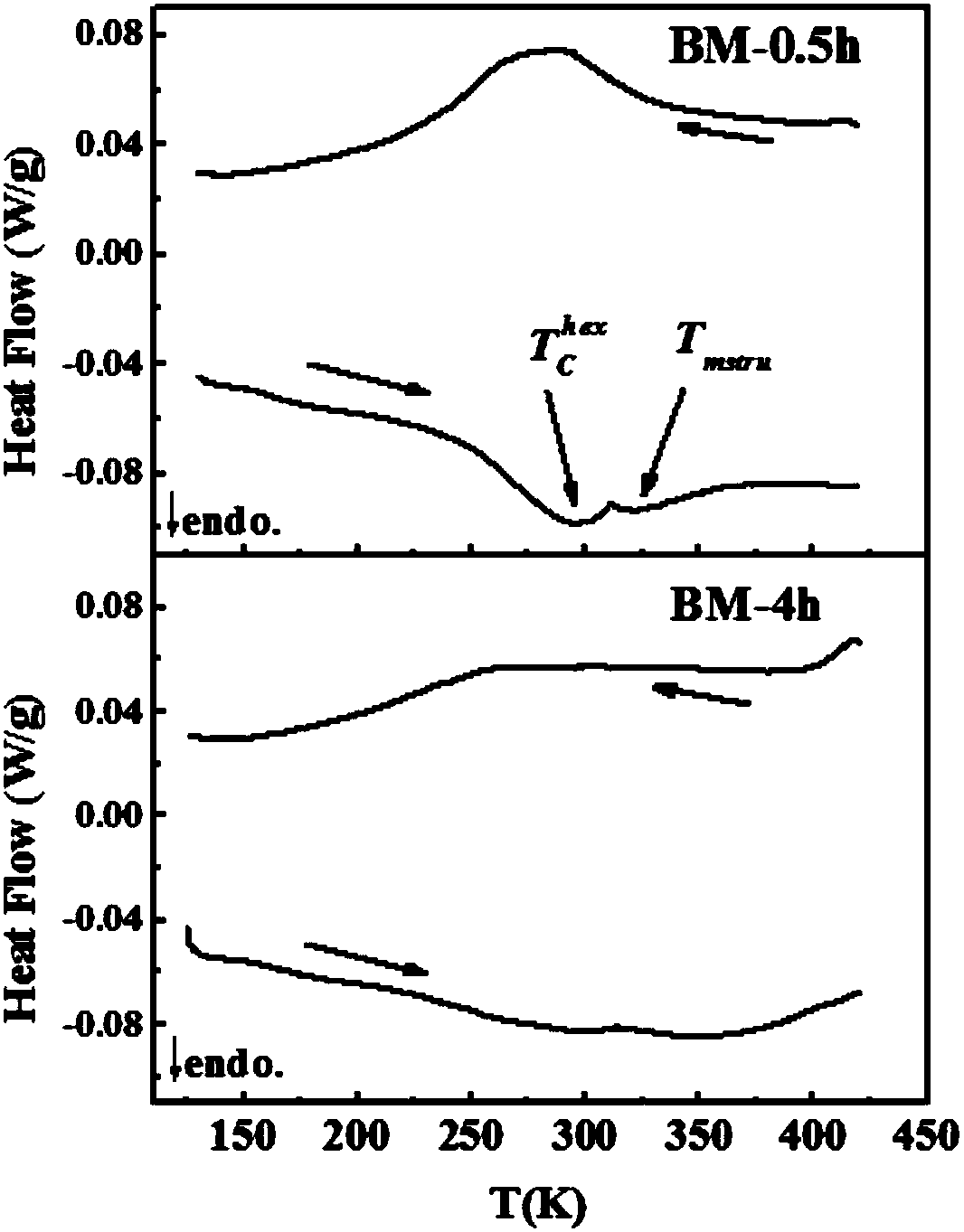

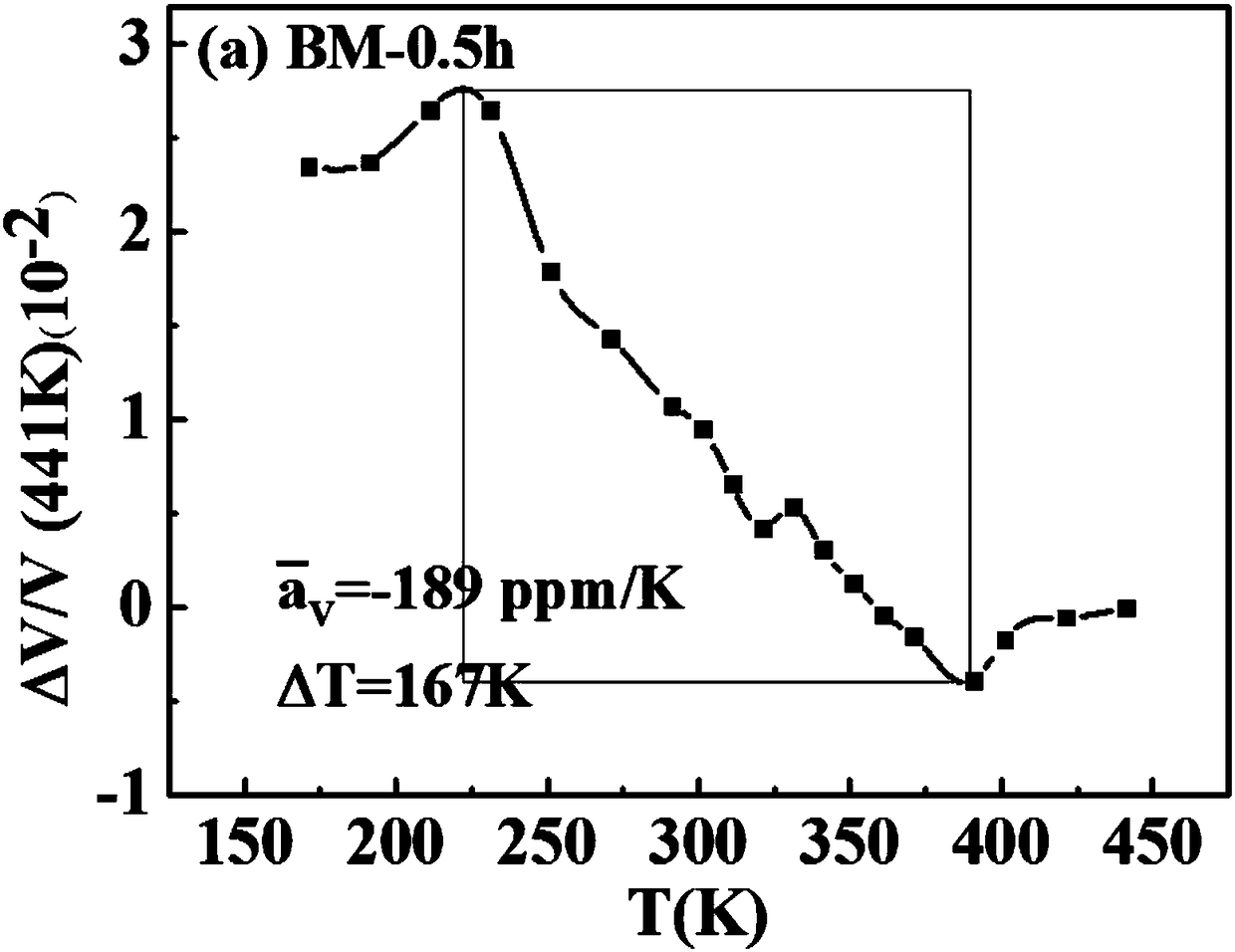

Embodiment 1

[0024] Alloys are designed according to principle, specifically Mn 0.965 co 1.035 Ge, the preparation steps are as follows:

[0025] S1. Dosing: According to the stoichiometric ratio, calculate the mass of the required Mn, Co, and Ge element elements, generally accurate to 0.1 mg, and the purity of the metal elements is above 99.99%. For volatile metals, appropriately increase the amount to compensate for the loss during the smelting process, such as Mn, for MnCoGe-based alloy samples, consider adding 3-10wt.% more;

[0026] S2. Carry out electric arc melting: put the prepared raw materials into a water-cooled copper crucible electric arc furnace, and pump the vacuum to 5×10 - 3 Below Pa, fill in argon gas with a purity of 99.999% at 1 atmosphere, and carry out arc melting. During the first smelting, melt the metal with a current of 28A. Just see the molten metal flowing in the crucible, and melt the first smelting Turn the block sample over, slightly increase the current ...

Embodiment 2

[0030] Alloys are designed according to principle, specifically Mn 0.965 co 1.035 Ge, the preparation steps are as follows:

[0031] S1. Dosing: According to the stoichiometric ratio, calculate the mass of the required Mn, Co, and Ge element elements, generally accurate to 0.1 mg, and the purity of the metal elements is above 99.99%. For volatile metals, appropriately increase the amount to compensate for the loss during the smelting process, such as Mn, for MnCoGe-based alloy samples, consider adding 3-10wt.% more;

[0032] S2. Carry out electric arc melting: put the prepared raw materials into a water-cooled copper crucible electric arc furnace, and pump the vacuum to 5×10 - 3 Below Pa, fill in argon gas with a purity of 99.999% at 1 atmosphere, and carry out arc melting. During the first smelting, melt the metal with a current of 28A. Just see the molten metal flowing in the crucible, and melt the first smelting Turn the block sample over, slightly increase the current ...

Embodiment 3

[0036] This embodiment designs the alloy according to the principle, Mn 1-x co 1+x In Ge, (x=0.015, x=0.02), namely Mn 0.985 co 1.015 Ge and Mn 0.98 co 1.02 Ge,

[0037] The difference between this embodiment and Embodiment 1 lies in that in step S3, the rotational speed of the high-energy ball milling process is 300 rpm, after the high-energy ball milling treatment, the ball milling time is 10 h. Other steps and selected parameters are the same as in Example 1. As a result, a sample with a large negative thermal expansion in a wide temperature range was obtained, and the Mn 0.985 co 1.015 Ge and Mn 0.98 co 1.02 Ge, a martensitic phase transformation with a wide temperature range was observed in the sample, and a huge negative thermal expansion in a wide temperature range was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com