A preparation method of wc-co thermal spray powder with liquid phase sintered structure characteristics

A technology of thermal spraying powder and liquid phase sintering, which is applied in coating, molten spraying, metal processing equipment, etc. It can solve the problems of particle adhesion and reduce fluidity, and achieve high yield, high fluidity, and liquid phase sintering The effect of cemented carbide microstructure characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

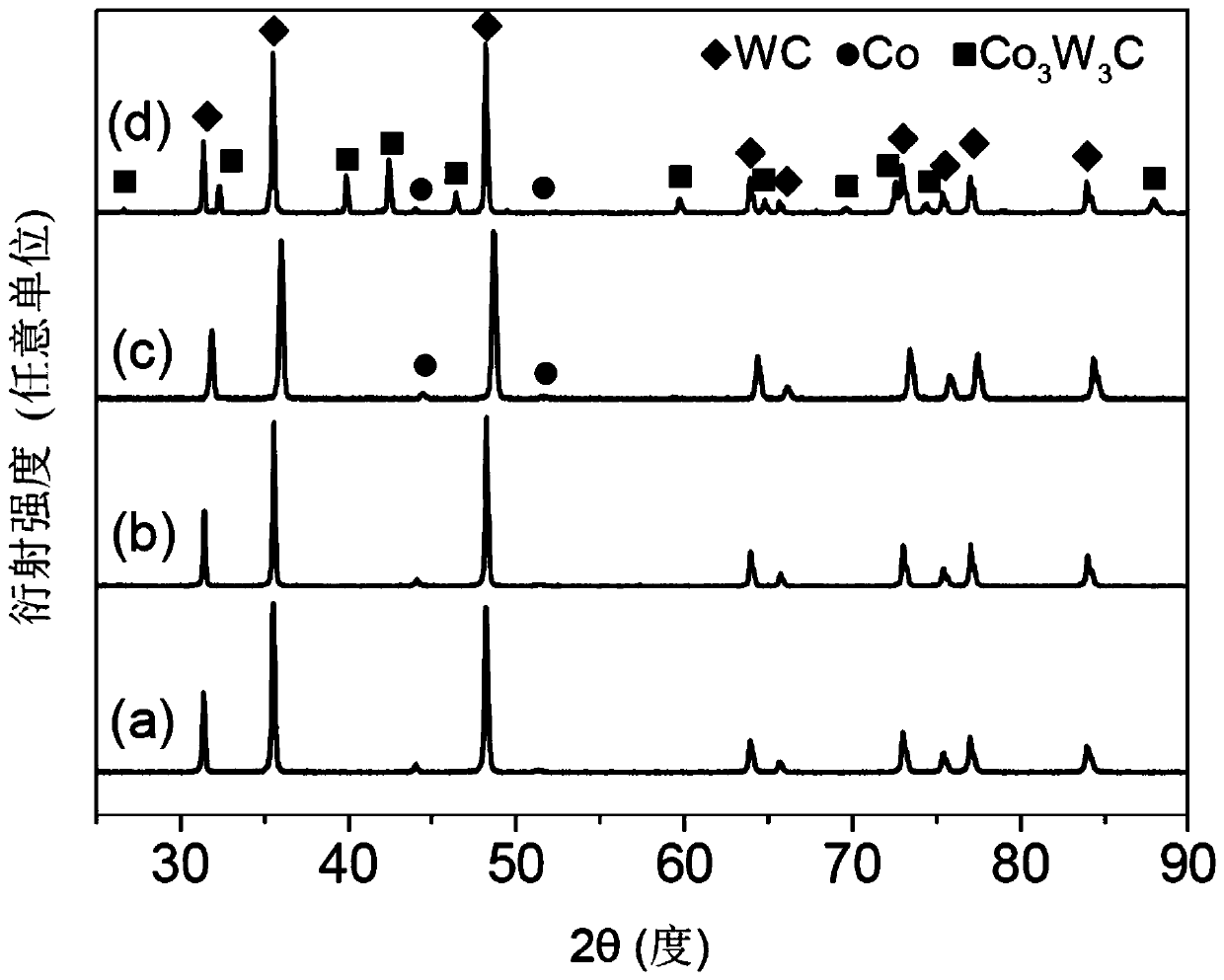

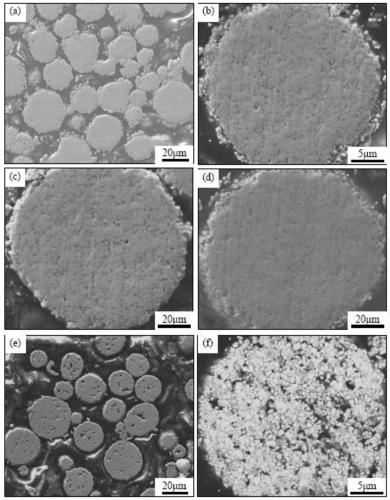

[0015] The WC-Co spherical powder of 15-45 microns, the brown corundum powder of 75-150 microns and the carbon black powder with a particle size of less than 0.5 microns are mechanically stirred and mixed in a certain proportion, and the mass of the brown corundum powder and the WC-Co spherical powder The ratio is 3:1, the mass of carbon black powder is 1% of the WC-Co spherical powder; the above mixed powder is placed in a vacuum furnace for heat treatment, the heat treatment temperature is 1390 ° C, the holding time is 1.5 h, and the furnace temperature rises to 1200 At ℃, 100mbar argon gas is introduced, and after the heat treatment is completed, it is cooled to room temperature with the furnace; the heat-treated powder is passed through a 325-mesh sieve, and the powder that passes through the sieve is collected to obtain a WC-Co thermal spray coating with liquid phase sintered structure characteristics. powder. Utilize X-ray diffraction analysis to detect the phase purity ...

Embodiment 2

[0017] The WC-Co spherical powder of 15-45 microns, the brown corundum powder of 75-150 microns and the carbon black powder with a particle size of less than 0.5 microns are mechanically stirred and mixed in a certain proportion, and the mass of the brown corundum powder and the WC-Co spherical powder The ratio is 4:1, the mass of carbon black powder is 1.5% of the WC-Co spherical powder; the above mixed powder is placed in a vacuum furnace for heat treatment, the heat treatment temperature is 1400°C, the holding time is 1h, and the furnace temperature rises to 1200°C 150mbar of argon gas is introduced, and after the heat treatment is completed, it is cooled to room temperature with the furnace; the heat-treated powder is passed through a 325 mesh sieve, and the powder that passes through the sieve is collected to obtain a WC-Co thermal spray powder with liquid phase sintered structure characteristics. . Utilize X-ray diffraction analysis to detect the phase purity of the spra...

Embodiment 3

[0019] The WC-Co spherical powder of 15-45 microns, the brown corundum powder of 75-150 microns and the carbon black powder with a particle size of less than 0.5 microns are mechanically stirred and mixed in a certain proportion, and the mass of the brown corundum powder and the WC-Co spherical powder The ratio is 5:1, the mass of carbon black powder is 2% of the WC-Co spherical powder; the above mixed powder is placed in a vacuum furnace for heat treatment, the heat treatment temperature is 1420 °C, the holding time is 0.5h, and the furnace temperature rises to 1200 At ℃, 150mbar argon gas is introduced, and after the heat treatment is completed, it is cooled to room temperature with the furnace; the heat-treated powder is passed through a 325 mesh sieve, and the powder that passes through the sieve is collected to obtain a WC-Co thermal spray coating with liquid phase sintered structure characteristics. powder. Utilize X-ray diffraction analysis to detect the phase purity of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com